5 Core Elements of a Robust Warehouse Operations Strategy

A well-developed warehouse operations strategy is crucial for organizations that rely on efficient logistics and supply chain management. Identifying the right mix of people, processes, and technology is essential to optimize your warehouse's operations. A robust warehouse operations strategy helps organizations establish standardized processes, procedures, and metrics to streamline operations and minimize errors, leading to increased efficiency and cost savings. In this article, we will explore the five core elements that constitute a robust warehouse operations strategy.

The Importance of a Strong Warehouse Operations Strategy

A strong warehouse operations strategy enhances customer satisfaction and helps businesses maintain a competitive edge. According to the Supply Chain 2023 Report, companies with optimized warehouse strategies see a 15% increase in on-time deliveries and a 20% reduction in operational costs. A robust strategy ensures that products are delivered to customers on time and in optimal condition. It helps reduce cycle times, maintain optimal inventory levels, minimize errors, and streamline communication between different stakeholders in the supply chain.

Additionally, a strong warehouse operations strategy enables businesses to adapt to changing market conditions and customer demands. With a flexible strategy in place, organizations can quickly respond to fluctuations in demand, adjust inventory levels, and optimize their operations to meet evolving customer needs. This agility is critical in today's fast-paced business environment, where companies must pivot swiftly to stay ahead of the competition.

Finally, a robust warehouse operations strategy can improve sustainability and reduce environmental impact. By optimizing operations, reducing waste, and minimizing energy consumption, organizations can lower their carbon footprint and contribute to a more sustainable future. This not only benefits the environment but also enhances the company's reputation and appeals to environmentally conscious customers.

Understanding the Role of Your Warehouse in Your Supply Chain

A warehouse plays a pivotal role in the supply chain, serving as the hub where goods are stored, sorted, and dispatched to their final destination. To develop a strong warehouse operations strategy, it is essential to understand the critical role your warehouse plays within the supply chain. Key factors include the flow of goods, inventory levels, storage capacity, and delivery times.

- Flow of Goods: Efficiently managing the movement of goods from suppliers to customers.

- Inventory Levels: Maintaining optimal stock to meet demand without overstocking.

- Storage Capacity: Utilizing space effectively to maximize storage while ensuring accessibility.

- Delivery Times: Ensuring timely dispatch and delivery of products to customers.

Understanding these elements enables organizations to develop a comprehensive and effective warehouse operations plan. A well-managed warehouse can reduce costs throughout the supply chain by optimizing inventory levels and minimizing the time goods spend in storage, thereby freeing up capital and reducing transportation costs.

Furthermore, leveraging technology such as Warehouse Management Systems (WMS) can automate and optimize warehouse operations, improving inventory accuracy, reducing labor costs, and increasing overall efficiency.

Identifying Key Performance Indicators (KPIs) for Warehouse Operations

Key Performance Indicators (KPIs) are essential metrics used to evaluate the effectiveness and efficiency of an organization's warehouse operations. According to industry studies, organizations that actively monitor KPIs experience a 25% improvement in warehouse performance.

- Inventory Accuracy: Measures the precision of inventory records compared to actual stock.

- Order Accuracy: Tracks the percentage of orders correctly fulfilled without errors.

- On-Time Delivery: Monitors the punctuality of order deliveries to customers.

- Warehouse Capacity Utilization: Assesses how effectively warehouse space is being used.

Identifying the most critical KPIs allows organizations to take corrective actions and optimize warehouse performance. For example, cycle time, which measures the time taken for a product to move through the warehouse from receiving to shipping, helps identify bottlenecks and streamline processes. Similarly, the picking accuracy rate ensures customer satisfaction by minimizing errors and reducing costs associated with returns and re-shipping.

Regularly reviewing and adjusting KPIs ensures they remain aligned with organizational goals and adapt to changing business environments. This continuous monitoring enables organizations to stay agile and responsive to market conditions and customer needs.

How to Develop a Comprehensive Warehouse Operations Plan

A comprehensive warehouse operations plan outlines all activities required to move goods through the warehouse, from receiving to shipping. Developing an effective plan involves:

- Identifying Critical Processes: Pinpointing essential operations such as receiving, storing, picking, packing, and shipping.

- Resource Allocation: Determining the necessary resources, including workforce, equipment, and technology.

- Defining Workflows: Mapping out step-by-step procedures to ensure consistency and efficiency.

- Establishing Policies: Creating guidelines for operations, safety, and quality management.

Incorporating technology is also crucial. Tools like WMS, barcode scanners, and RFID readers enhance accuracy and streamline operations. Additionally, prioritizing employee safety by implementing safety protocols, providing proper training, and maintaining equipment is essential for a secure and efficient warehouse environment.

Having a contingency plan for unexpected events, such as natural disasters or equipment failures, ensures minimal disruptions to warehouse operations. By prioritizing safety and preparedness, organizations can create a comprehensive warehouse operations plan that not only increases efficiency but also protects employees and assets.

Optimizing Inventory Management for Increased Efficiency and Cost Savings

Optimizing inventory management is a fundamental element of a robust warehouse operations strategy. It involves:

- Tracking Inventory Levels: Utilizing real-time data to monitor stock levels and movements.

- Maintaining Safety Stock: Ensuring adequate stock to prevent stockouts during demand fluctuations.

- Accurate Inventory Accounting: Keeping precise records to avoid discrepancies and losses.

Organizations must deploy a robust inventory management system to track the movement of materials, ensure optimal stock levels, and avoid stockouts. According to a study by Warehouse Management News, optimized inventory management can reduce carrying costs by up to 30% and minimize losses due to obsolescence and stockouts.

Effective inventory management also enhances order fulfillment accuracy, leading to higher customer satisfaction and reduced costs associated with returns and reshipping. By leveraging data analytics and forecasting tools, organizations can anticipate demand trends and adjust inventory levels proactively.

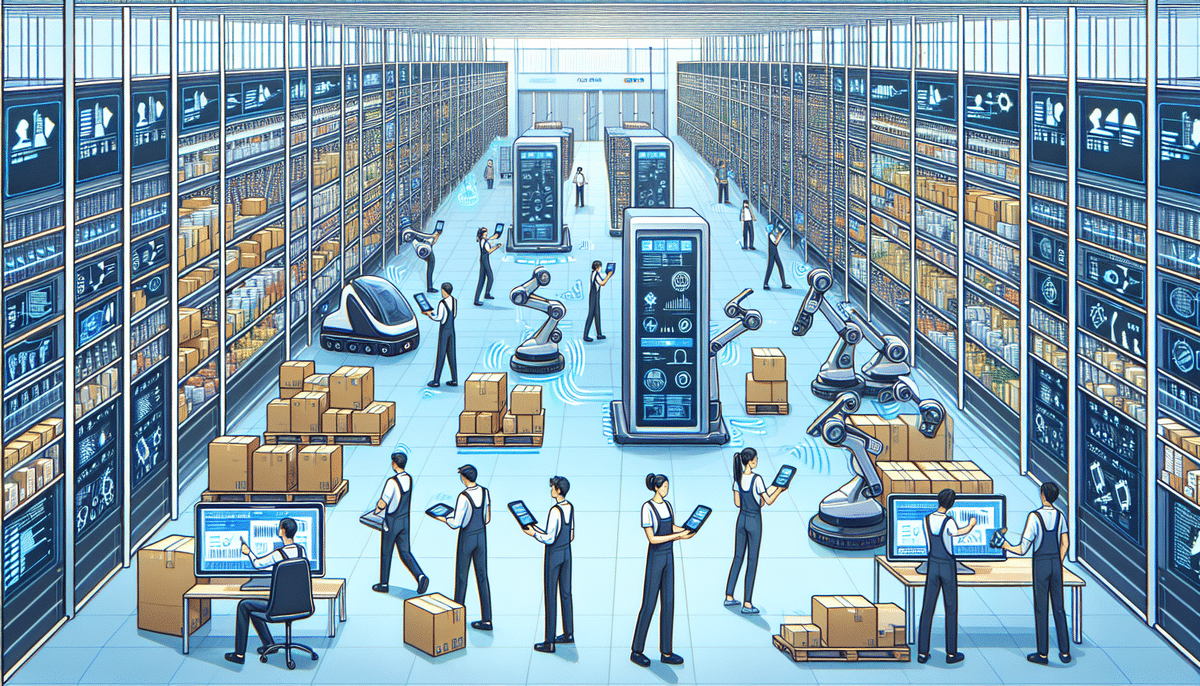

Harnessing Technology to Streamline Warehouse Operations

Technological innovations have revolutionized warehouse operations, enabling efficient inventory management, process control, and workflow automation. Key technologies include:

- Warehouse Management Systems (WMS): Provide real-time inventory tracking, streamline order processing, and enhance shipment tracking.

- Robotics: Automate repetitive tasks such as picking, packing, and sorting, reducing labor costs and increasing speed.

- Automated Storage and Retrieval Systems (ASRS): Optimize storage space and improve retrieval efficiency.

- Artificial Intelligence (AI): Enhance predictive analytics for demand forecasting and inventory optimization.

Organizations that harness these technologies benefit from increased efficiency, reduced costs, and improved accuracy. For instance, implementing AI-driven analytics can provide actionable insights into warehouse performance, enabling data-driven decision-making. Moreover, automation reduces human error, enhances safety, and allows employees to focus on higher-value tasks.

Investing in the latest technologies ensures that organizations stay competitive and can adapt to evolving market demands. According to a report by Tech Warehouse, warehouses utilizing advanced technology experience a 40% increase in operational efficiency.

Effective Employee Training and Management in the Warehouse Environment

Employees are the backbone of warehouse operations. Proper training ensures that employees understand their roles and how they contribute to the organization's goals. Key aspects of effective employee training and management include:

- Role-Specific Training: Providing training tailored to specific job functions, such as operating equipment or managing inventory.

- Safety Training: Educating employees on safety protocols to prevent accidents and ensure a safe working environment.

- Continuous Development: Offering ongoing training programs to enhance skills and promote professional growth.

- Performance Management: Implementing performance metrics and regular evaluations to recognize achievements and identify areas for improvement.

According to the SHRM Warehouse Training Research, organizations that invest in comprehensive training programs see a 25% improvement in employee productivity and a 15% reduction in turnover rates.

Creating a positive work environment and fostering a culture of continuous improvement not only boosts employee morale but also enhances overall warehouse performance. By empowering employees with the necessary skills and knowledge, organizations can achieve higher efficiency and better operational outcomes.

Mitigating Risks and Ensuring Compliance with Industry Standards and Regulations

Compliance with industry standards and regulations is paramount for warehouse operations. Adhering to guidelines set by the OSHA and other regulatory bodies ensures a safe and legally compliant workplace. Key strategies for mitigating risks and ensuring compliance include:

- Risk Assessment: Conducting regular risk assessments to identify potential hazards and implement appropriate controls.

- Safety Protocols: Establishing and enforcing safety procedures to prevent workplace accidents and injuries.

- Environmental Compliance: Adhering to environmental regulations to minimize the warehouse's ecological footprint.

- Insurance Coverage: Securing appropriate insurance policies to protect against potential liabilities and losses.

Developing a comprehensive risk assessment plan is essential to minimize the risk of workplace accidents, injuries, and property damage. Implementing safety protocols, providing proper training, and ensuring regular maintenance of equipment contribute to a safe and efficient warehouse environment.

Furthermore, staying updated with the latest industry regulations and standards ensures ongoing compliance and helps avoid legal penalties. Organizations should regularly review and update their compliance strategies to align with evolving regulations and industry best practices.

The Role of Data Analytics in Improving Warehouse Operations

Data analytics plays a crucial role in modern warehouse operations by providing actionable insights into performance and efficiency. Utilizing analytics tools allows warehouse managers to:

- Analyze Performance Trends: Identify patterns and trends in operational data to make informed decisions.

- Optimize Processes: Streamline workflows based on data-driven insights to enhance efficiency.

- Improve Customer Service: Use data to ensure timely and accurate order fulfillment, leading to higher customer satisfaction.

- Boost Efficiency: Identify areas of waste and implement strategies to reduce costs and increase productivity.

According to a report by Analytics Warehouse, warehouses that leverage data analytics experience a 35% improvement in operational efficiency and a 20% increase in order accuracy.

Organizations must collect, analyze, and utilize warehouse performance data continuously to evaluate and enhance their operations. By leveraging data analytics, organizations can make informed decisions that lead to improved warehouse operations, reduced costs, and increased efficiency. Implementing predictive analytics can also help forecast demand, optimize inventory levels, and prevent potential disruptions.

Best Practices for Managing Inbound and Outbound Logistics

Effective management of inbound and outbound logistics is critical for optimizing supply chain efficiency. Best practices in this area include:

- Efficient Transportation Networks: Develop reliable transportation and delivery networks to ensure timely movement of goods.

- Clear Communication Channels: Establish transparent communication between suppliers, warehouse staff, and customers to facilitate smooth operations.

- Goods Tracking: Utilize tracking systems to monitor the movement of goods throughout the supply chain.

- Supplier Relationship Management: Foster strong relationships with suppliers to ensure timely and quality deliveries.

Implementing these best practices enables organizations to optimize supply chain efficiency, reduce costs, and enhance customer satisfaction. Advanced technologies such as logistics management software can further streamline these processes by providing real-time visibility and control over inbound and outbound logistics.

Additionally, adopting just-in-time (JIT) inventory practices can minimize inventory holding costs and reduce waste by ensuring that goods are received and dispatched precisely when needed.

Balancing Flexibility and Scalability in Your Warehouse Strategy

Flexibility and scalability are essential components of a successful warehouse operations strategy. A warehouse must adapt to sudden changes in demand, new product offerings, and seasonal fluctuations. Key strategies to balance flexibility and scalability include:

- Facility Design: Design warehouse layouts that can be easily reconfigured to accommodate changing needs.

- Scalable Technology: Invest in technology that can scale with business growth and adapt to new operational requirements.

- Flexible Workforce: Develop a workforce strategy that allows for scalability, such as cross-training employees to perform multiple roles.

- Modular Systems: Implement modular storage and handling systems that can expand or contract based on demand.

By considering factors such as facility size, location, workforce, and technology, organizations can create a warehouse strategy that is both flexible and scalable. This balance enables organizations to respond quickly to changing market conditions and customer needs, ultimately leading to increased customer satisfaction and revenue growth.

For example, during peak seasons, scalable technology and a flexible workforce allow warehouses to handle increased order volumes efficiently without compromising on service quality.

Building a Resilient Supply Chain with a Strong Warehouse Operations Strategy

A strong warehouse operations strategy is a cornerstone of a resilient supply chain. Resilience in the supply chain refers to the ability to withstand and recover from disruptions such as natural disasters, market fluctuations, or logistical challenges. Key elements of building a resilient supply chain include:

- Diversified Suppliers: Establish relationships with multiple suppliers to reduce dependency on a single source.

- Redundant Systems: Implement redundant systems and processes to ensure continuity of operations during disruptions.

- Risk Management: Develop comprehensive risk management plans to anticipate and mitigate potential disruptions.

- Collaborative Partnerships: Foster collaboration with partners and stakeholders to enhance collective resilience.

Organizations that invest in developing a robust warehouse operations strategy are better equipped to weather disruptions and maintain uninterrupted service. This resilience ensures that products are delivered on time, customer satisfaction remains high, and the organization can continue to grow and succeed despite challenges.

According to the Resilient Supply Chain Study, companies with resilient supply chains experience 50% less downtime during disruptions and recover 30% faster than their competitors.

Measuring Success: Evaluating the Effectiveness of Your Warehouse Operations Strategy

The final core element of a strong warehouse operations strategy is measuring success. Regular evaluation of warehouse performance against key performance indicators (KPIs) and other metrics ensures that the strategy remains aligned with organizational goals and adapts to changing needs. Key steps in measuring success include:

- Regular Performance Reviews: Conduct periodic assessments of warehouse operations to identify strengths and areas for improvement.

- Data-Driven Insights: Utilize data analytics to gain insights into operational performance and identify trends.

- Continuous Improvement: Implement a culture of continuous improvement by making data-driven adjustments to processes and strategies.

- Stakeholder Feedback: Gather feedback from employees, suppliers, and customers to inform strategy adjustments.

By measuring success, organizations can ensure that their warehouse operations strategy remains effective, relevant, and optimized for their needs. Regular evaluation allows organizations to identify and address inefficiencies, capitalize on strengths, and adapt to evolving business landscapes.

In conclusion, a robust warehouse operations strategy is essential for organizations engaged in logistics and supply chain management. The five core elements include understanding the warehouse's role in the supply chain, identifying key performance indicators, developing a comprehensive operations plan, optimizing inventory management, and harnessing technology. Additional elements such as effective employee training, risk mitigation, managing logistics, balancing flexibility and scalability, building a resilient supply chain, and measuring success further contribute to an effective warehouse operations strategy. By focusing on these elements, organizations can achieve enhanced efficiency, cost savings, and sustained growth.