Introduction to Warehouse Automation: 6 River Systems vs Fetch Robotics

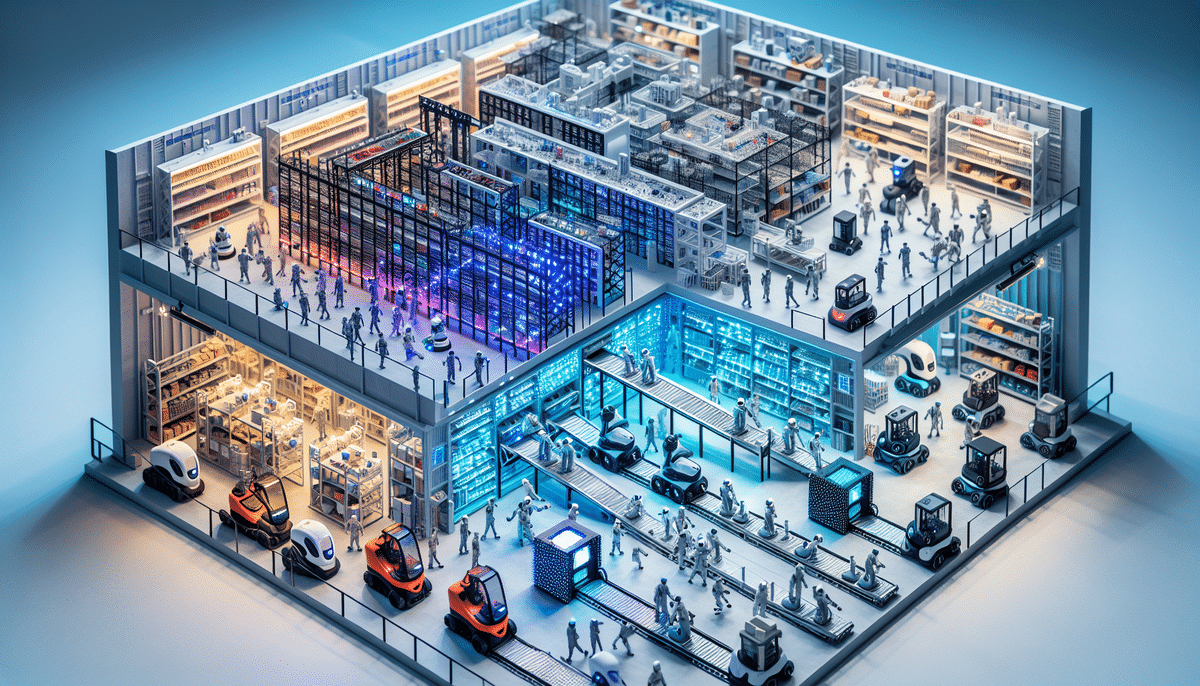

In the rapidly evolving landscape of warehouse automation, 6 River Systems, a subsidiary of Shopify, and Fetch Robotics have emerged as leading innovators. These companies offer state-of-the-art robotic systems designed to streamline warehouse operations, enhance efficiency, and reduce operational costs. This comprehensive comparison delves into the features, pricing, technical specifications, case studies, and future prospects of 6 River Systems and Fetch Robotics to help businesses make informed decisions about their warehouse automation strategies.

Overview of 6 River Systems and Fetch Robotics

6 River Systems, acquired by Shopify in 2019, specializes in collaborative robotics for warehouse operations. Their flagship product, the Chuck robot, is engineered to work alongside human workers, improving productivity and operational efficiency through intelligent task management and real-time coordination.

Fetch Robotics offers a diverse range of autonomous mobile robots (AMRs) designed for various warehouse tasks, including material transport, data collection, and inventory management. Their robots are built to integrate seamlessly with existing warehouse systems, offering scalability and flexibility to adapt to dynamic operational demands.

Both companies are at the forefront of warehouse automation, leveraging advanced robotics and artificial intelligence to meet the growing demands of the e-commerce boom and the necessity for rapid, accurate order fulfillment. According to Forbes, the global warehouse robotics market is expected to reach $30 billion by 2026, highlighting the critical role these companies play in shaping the future of logistics and supply chain management.

Key Differences Between 6 River Systems and Fetch Robotics

While both 6 River Systems and Fetch Robotics are prominent in warehouse automation, they adopt different approaches and target varied segments of the market:

- Collaboration vs. Autonomy: 6 River Systems' Chuck robot is designed for collaborative operations, working directly with human employees to enhance workflow. In contrast, Fetch Robotics focuses on creating fully autonomous robots that can operate independently with minimal human intervention.

- Market Focus: 6 River Systems primarily caters to e-commerce and retail warehouses, emphasizing agility and adaptability in narrow aisles. Fetch Robotics targets a broader range of industries, including manufacturing and distribution centers, with robots capable of handling heavier loads and traversing longer distances.

- Software Integration: 6 River Systems offers a cloud-based software platform for real-time monitoring and optimization, providing detailed analytics on productivity and inventory. Fetch Robotics provides a modular software solution that allows for extensive customization and integration with various warehouse management systems (WMS).

Features and Capabilities

Features of 6 River Systems

6 River Systems' Chuck robot is renowned for its collaborative capabilities and adaptive design:

- Collaborative Operation: Chuck seamlessly works alongside human workers, assisting with picking tasks and dynamically adapting to changes in workflow. This collaboration enhances overall productivity and reduces the physical strain on staff.

- Flexibility and Adaptability: Designed to navigate complex warehouse environments, Chuck can adjust to various layouts and configurations, ensuring efficient task execution across different settings.

- Advanced Safety Features: Equipped with sensors and obstacle detection technology, Chuck ensures safe interactions with human workers by avoiding collisions and responding to safety hazards in real-time.

- Real-Time Analytics: The integrated software platform provides valuable insights into warehouse operations, enabling continuous improvement and data-driven decision-making.

These features collectively enable warehouses to achieve higher efficiency levels, reduce error rates, and enhance worker satisfaction by automating repetitive and physically demanding tasks.

Features of Fetch Robotics

Fetch Robotics offers a versatile lineup of autonomous mobile robots tailored to various warehouse needs:

- Autonomous Navigation: Fetch's AMRs leverage advanced mapping and navigation algorithms to traverse warehouse floors autonomously, optimizing routes for efficiency.

- Modular Design: The robots are designed for easy integration with existing systems such as conveyor belts, barcode scanners, and inventory management software, providing a cohesive automation solution.

- Real-Time Reporting: Comprehensive analytics and reporting tools offer real-time visibility into robot performance and operational metrics, facilitating informed decision-making.

- Scalability: Fetch Robotics' solutions are scalable, allowing businesses to expand their automation capabilities as their operational needs grow.

Fetch Robotics' emphasis on autonomy and integration makes their robots suitable for businesses seeking to minimize human intervention and maximize operational flexibility.

Pros and Cons

Pros and Cons of 6 River Systems

Pros:

- Collaborative Efficiency: Enhances productivity by seamlessly integrating robots with human workflows.

- Flexibility: Adaptable to various warehouse layouts and operational changes.

- Advanced Analytics: Provides real-time data for continuous operational improvement.

- Safety: Robust safety features ensure secure interactions between robots and humans.

Cons:

- Dependency on Human Interaction: Requires human workers to interact and manage robot tasks, which might limit full automation aspirations.

- Initial Investment: High upfront costs involved in purchasing and integrating robots into existing systems.

- Training Requirements: Staff may need training to effectively collaborate with robotic systems, leading to temporary productivity dips during the transition period.

Pros and Cons of Fetch Robotics

Pros:

- High Autonomy: Robots can operate independently, reducing the need for constant human oversight.

- Scalability: Easily scalable to accommodate growing operational demands.

- Integration Capabilities: Compatible with a variety of existing warehouse management systems.

- Flexibility: Suitable for multiple industries beyond e-commerce, including manufacturing and hospitality.

Cons:

- Higher Cost: Autonomous robots may come with a higher price tag compared to collaborative solutions.

- Maintenance: Ongoing maintenance and repair costs can contribute to the overall cost of ownership.

- Learning Curve: Implementing and managing autonomous robots may require specialized knowledge and can pose a learning curve for staff.

Pricing and Cost Comparison

The cost structures of 6 River Systems and Fetch Robotics vary based on the scale and specific requirements of each deployment:

- 6 River Systems: The price for a single Chuck robot ranges between $25,000 and $50,000, depending on the configuration and integration complexity.

- Fetch Robotics: Fetch's AMRs typically start at around $80,000 and can exceed $150,000 for more advanced models with specialized functionalities.

It's crucial to consider not only the initial purchase costs but also ongoing expenses such as maintenance, software subscriptions, and potential upgrades. Both companies offer leasing options, which can mitigate upfront costs and provide businesses with flexibility to scale their automation as needed. For example, leasing a Chuck robot from 6 River Systems may cost approximately $1,500 per month, whereas leasing Fetch Robotics' AMRs might range from $2,000 to $3,000 per month.

Technical Specifications and Performance

When evaluating technical specifications, several key factors should be considered to determine which system aligns best with your operational needs:

- Robot Speed: Fetch Robotics' AMRs typically have higher movement speeds, ranging up to 2 meters per second, which can be advantageous for large warehouses.

- Payload Capacity: Fetch's robots often support greater payloads, making them suitable for transporting heavier items as opposed to 6 River Systems' Chuck, which excels in handling smaller, more agile items.

- Battery Life: Both systems offer robust battery life, with Chuck robots providing up to 8 hours of continuous operation and Fetch's AMRs supporting similar or extended durations with swappable battery systems.

- Navigation Technology: 6 River Systems utilizes proprietary navigation algorithms optimized for warehouse environments, while Fetch Robotics employs a combination of LIDAR and computer vision for precise autonomous movement.

Based on these specifications, Fetch Robotics may offer superior performance in environments requiring high-speed operations and larger payloads, while 6 River Systems provides efficient performance in collaborative settings with a focus on agility and flexibility.

Customer Support and Service

Both 6 River Systems and Fetch Robotics prioritize customer support, offering comprehensive services to ensure successful implementation and ongoing operation:

- 6 River Systems: Provides dedicated account managers, extensive training programs, and 24/7 technical support. However, some users have reported delays in response times during peak periods.

- Fetch Robotics: Offers robust customer support with real-time monitoring, proactive maintenance, and a dedicated support team. Customers have noted Fetch's prompt and reliable assistance in troubleshooting and system optimization.

Overall, Fetch Robotics tends to receive higher ratings for customer satisfaction, particularly regarding response times and support effectiveness, whereas 6 River Systems may benefit from enhancing their support infrastructure to match industry standards.

Case Studies: Success Stories

Several leading companies have implemented 6 River Systems and Fetch Robotics solutions with notable success:

- 6 River Systems: Office Depot and XPO Logistics have integrated Chuck robots into their warehouses, reporting significant increases in pick rates and operational efficiency.

- Fetch Robotics: GE Healthcare and DHL have deployed Fetch's AMRs, achieving improvements in material handling speed and accuracy, as well as enhanced data collection capabilities.

For instance, DHL reported a 30% increase in efficiency and a 25% reduction in operational costs after implementing Fetch Robotics' solutions (Source). Similarly, XPO Logistics saw a 50% improvement in order fulfillment speed upon adopting 6 River Systems' Chuck robots (Source).

Future of Warehouse Automation: Industry Predictions

The warehouse automation industry is poised for substantial growth and innovation. Key trends and predictions include:

- Integration of AI and Machine Learning: Advanced AI algorithms will enable robots to make more autonomous decisions, optimize task workflows, and predict maintenance needs.

- Increased Collaboration between Humans and Robots: Future systems will likely see a deeper integration of collaborative robots (cobots) that work alongside humans with enhanced safety and communication capabilities.

- Expansion into New Industries: While e-commerce currently leads in warehouse automation adoption, sectors like healthcare, automotive, and food and beverage are expected to increasingly integrate robotic solutions.

- Sustainability Focus: Robotics manufacturers will emphasize energy-efficient designs and sustainable materials to align with global sustainability goals.

- Enhanced Data Analytics: Robotic systems will provide more granular data analytics, enabling precise optimization of warehouse operations and supply chain management.

Both 6 River Systems and Fetch Robotics are well-positioned to capitalize on these trends, continuously evolving their technologies to meet the future demands of the warehouse automation landscape.

Conclusion: Choosing the Right Automation System

Deciding between 6 River Systems and Fetch Robotics hinges on your specific warehouse requirements, operational goals, and budgetary constraints. Consider the following when making your choice:

- Operational Needs: If your operations require significant human-robot collaboration, 6 River Systems offers a robust solution. For fully autonomous operations, Fetch Robotics is the better choice.

- Budget Considerations: Evaluate both initial and long-term costs, including potential leasing options and total cost of ownership.

- Scalability and Flexibility: Consider your growth projections and whether the system can scale accordingly while maintaining flexibility to adapt to changing operational demands.

- Integration Capabilities: Ensure the chosen system can seamlessly integrate with your existing warehouse management systems and technologies.

- Customer Support: Assess the quality and responsiveness of the company's customer support services to ensure smooth implementation and ongoing operations.

Ultimately, both 6 River Systems and Fetch Robotics offer comprehensive, innovative solutions for warehouse automation. Conducting a thorough evaluation, including potential pilot programs and consultations with industry experts, will help determine the most suitable system to enhance your warehouse operations and drive future growth.