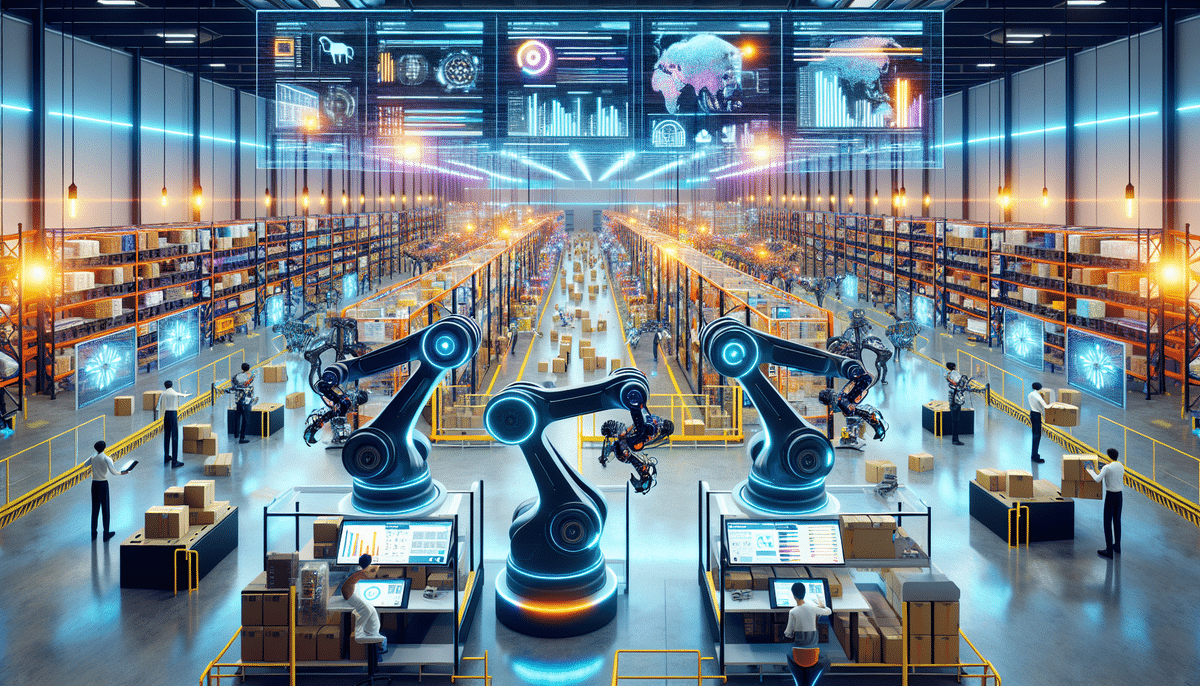

Introduction: The Growing Popularity of Robotics in eCommerce

In recent years, the eCommerce sector has experienced a significant shift towards automation and robotics. With global eCommerce sales projected to surpass $6.4 trillion by 2024 [1], businesses are continuously seeking ways to enhance efficiency, speed, accuracy, and cost-effectiveness in their operations. Robotics has emerged as a pivotal element in this transformation, offering advanced automation solutions that address these demands.

One of the primary advantages of integrating robotics into eCommerce operations is the ability to manage large volumes of orders swiftly and precisely. Automated systems enable businesses to process orders faster, significantly reducing fulfillment times and enhancing customer satisfaction. This technological advancement not only boosts competitiveness but also allows for scalability in response to increasing market demands.

Additionally, robotics helps businesses reduce labor costs and enhance workplace safety. By automating repetitive and hazardous tasks, companies can minimize the risk of workplace injuries and improve overall employee well-being. Robots can operate around the clock without the need for breaks, thereby increasing productivity and reducing reliance on human labor.

Overview of 6 River Systems and Locus Robotics

6 River Systems is a leading fulfillment automation company founded in 2015, now a part of Shopify. It offers a comprehensive automation solution that includes collaborative mobile robots, cloud-based software, and advanced assignment optimization algorithms.

Locus Robotics, established in 2014, specializes in autonomous mobile robots designed for warehouse automation. The company has gained traction among eCommerce businesses of varying sizes, thanks to its reliable and adaptable robotic solutions.

Both 6 River Systems and Locus Robotics have significantly impacted the warehouse automation landscape. 6 River Systems focuses on collaborative robots that work alongside human employees, enhancing efficiency and productivity through real-time data analytics. In contrast, Locus Robotics emphasizes autonomous navigation and independent operation, offering flexible integration with existing warehouse systems tailored to specific business needs.

Comparison of Key Features and Capabilities

6 River Systems provides a range of features aimed at optimizing picking, put-away, and replenishment processes. Its system reduces manual labor, increases productivity, and is highly scalable and customizable. The seamless integration with various warehouse management systems (WMS) makes it a versatile choice for diverse business environments.

Locus Robotics focuses on enhancing warehouse efficiency through effective order picking and transport solutions. Key features include a reliable navigation system, an intuitive user interface, and adaptable warehouse execution software, which collectively contribute to streamlined operations.

- Collaborative Robots: 6 River Systems’ mobile robots collaborate directly with human workers, utilizing sensors and cameras for obstacle avoidance and efficient navigation.

- Multi-Bot Solutions: Locus Robotics offers multi-bot configurations, enabling multiple robots to work in tandem, significantly speeding up task completion in high-volume settings.

- Real-Time Analytics: Both systems provide real-time data and analytics for informed decision-making and operational optimization.

User Interface and Ease of Use

The user interfaces of both 6 River Systems and Locus Robotics are designed for intuitiveness and user-friendliness. Locus Robotics features a straightforward interface that simplifies the training process for new employees, allowing them to adapt quickly and work efficiently.

6 River Systems offers a software platform that provides detailed instructions for warehouse tasks, fostering an excellent learning environment for new hires. Both systems support customization of the user interface, enabling companies to tailor the software to their specific operational needs. Locus Robotics utilizes a drag-and-drop interface for easy customization, while 6 River Systems provides more advanced options for businesses requiring specialized configurations.

Performance Analysis: Speed, Accuracy, and Reliability

Both 6 River Systems and Locus Robotics deliver fast and accurate automation solutions for warehouses. Their systems are built to operate reliably in dynamic environments, maintaining high levels of accuracy and speed regardless of changes in warehouse conditions.

6 River Systems incorporates a "Pick to Light" feature, which uses visual indicators to guide workers to the correct items, enhancing picking accuracy and speed. This reduces the time spent searching for items and minimizes errors.

Locus Robotics introduces a "gamification" element, motivating workers to complete tasks efficiently by turning work into an engaging game. This approach not only speeds up task completion but also maintains high accuracy levels.

Both companies offer real-time data analytics, allowing warehouse managers to monitor performance metrics and identify areas for improvement. This data-driven approach supports workflow optimization, error reduction, and overall efficiency enhancement. Additionally, both companies are known for their excellent customer support, providing dedicated teams to assist with any operational issues.

Integration and Compatibility with Existing Systems

Integration and compatibility are crucial considerations when selecting an automation system. Both 6 River Systems and Locus Robotics offer flexible integration with existing warehouse management systems (WMS), including platforms like Shopify, which is particularly beneficial for eCommerce businesses.

They provide robust APIs that facilitate seamless integration with third-party software tools, such as accounting software and customer relationship management (CRM) systems. This ensures that businesses can maintain cohesive operations across various software platforms.

Compatibility with existing hardware infrastructure is another important aspect. Both systems are designed to work with a wide range of hardware, including different types of mobile robots and sensors. This flexibility allows businesses to select hardware that best fits their specific needs and budget without facing compatibility issues.

Cost Analysis: Upfront and Long-Term Expenses

Both 6 River Systems and Locus Robotics offer competitive pricing structures, with costs varying based on warehouse size, system complexity, installation, maintenance, and upgrades. Despite the initial investment, both systems promise a strong return on investment (ROI) through long-term cost savings and operational efficiencies.

The upfront costs of implementing robotic systems may appear substantial, but the long-term benefits—such as increased efficiency, accuracy, and productivity—often outweigh these initial expenses. These enhancements can lead to higher profits and an improved customer experience.

Customization capabilities also influence cost. Both 6 River Systems and Locus Robotics offer tailored solutions to meet specific warehouse requirements. While customization may increase initial costs, it can result in greater efficiency and cost savings over time, making the investment worthwhile.

Customer Reviews and Feedback

Customers have lauded both 6 River Systems and Locus Robotics for their speed, accuracy, and reliability. Positive feedback often highlights the systems' ability to enhance operational efficiency and the supportive customer service provided by both companies.

6 River Systems is particularly praised for its user-friendly interface, which reduces training time and boosts productivity. Users appreciate the intuitive design and comprehensive instructions that facilitate seamless integration into existing workflows.

Locus Robotics receives commendations for its flexibility and adaptability. Customers value the system’s ability to customize operations to their specific needs and workflows, which enhances overall efficiency and effectiveness.

Cost-effectiveness is another critical factor for customers. While both systems are considered affordable relative to other warehouse automation solutions, some customers have found one system to be more financially suitable for their particular business needs. The long-term savings in labor costs and increased efficiency further justify the initial investment.

Case Studies: Successful Implementations Across Industries

DHL implemented 6 River Systems in its warehouse operations and reported a 2-3x increase in productivity [2]. This substantial improvement highlights the system's capability to enhance operational efficiency significantly.

Radial, an eCommerce fulfillment provider, adopted Locus Robotics and experienced a 200% increase in productivity [3]. This demonstrates the effectiveness of Locus Robotics in scaling operations to meet high-volume demands.

In the healthcare sector, a California-based hospital implemented 6 River Systems to automate the transportation of medical supplies. This integration resulted in a significant reduction in restocking times, allowing medical staff to focus more on patient care [4].

Within the food and beverage industry, a major beverage company adopted Locus Robotics to improve order fulfillment and reduce errors. Post-implementation, the company observed a 50% increase in productivity and a 40% reduction in errors [5].

Future Potential and Scalability for Business Growth

Both 6 River Systems and Locus Robotics offer scalable solutions designed to grow alongside your business. Their systems are easily adaptable and can be updated to accommodate evolving warehouse requirements, providing businesses with the flexibility to enhance processes and operational efficiencies as needed.

Robotic systems also generate valuable data insights that inform strategic decision-making. By analyzing data on inventory levels, order fulfillment times, and employee productivity, businesses can identify areas for improvement and optimize their workflows for maximum efficiency.

Furthermore, the automation of repetitive tasks through robotics leads to significant cost savings by reducing labor expenses and minimizing errors. These efficiencies contribute to a healthier bottom line and enable businesses to allocate resources more effectively, fostering sustained growth and competitiveness in the market.

Conclusion: Choosing the Right Robotics System for Your eCommerce Business

Selecting a robotics system is a critical decision that involves evaluating factors such as cost, speed, accuracy, and scalability. Both 6 River Systems and Locus Robotics offer robust automation solutions designed to enhance efficiency and deliver long-term cost savings. The best choice depends on your business's specific needs, warehouse size, and budget constraints.

It's essential to assess each system's capabilities and how they align with your operational requirements. Consider factors like integration compatibility, customization options, and the level of support provided by the vendor. By thoroughly evaluating these aspects, you can make an informed decision that will drive your eCommerce business towards greater efficiency, productivity, and success.

Sources: