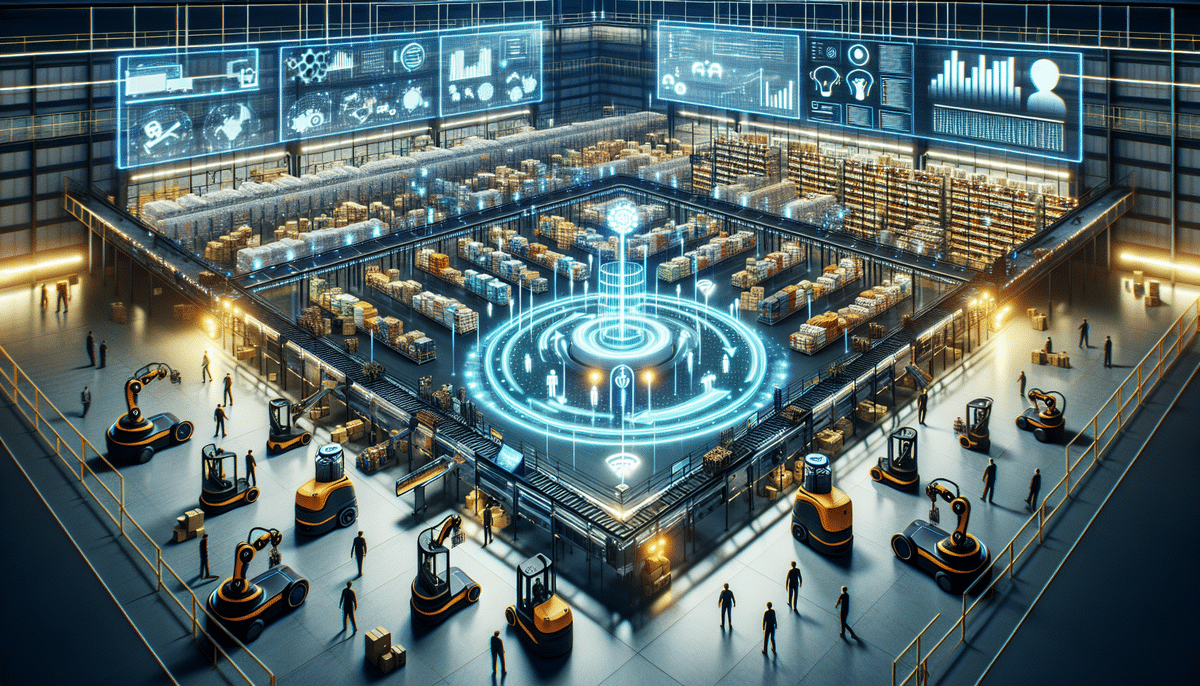

Locus Robotics vs GreyOrange: A Comprehensive Comparison

In the realm of e-commerce fulfillment, warehouse automation has emerged as a critical factor driving efficiency and competitiveness. Two frontrunners in this space are Locus Robotics and GreyOrange. These companies are at the forefront of transforming warehouse operations by leveraging advanced robotics and artificial intelligence. This article provides an in-depth analysis of the technologies, features, and strategies employed by Locus Robotics and GreyOrange to help businesses determine which solution is best suited for their e-commerce fulfillment and warehouse management needs.

Technological Advancements in Locus Robotics and GreyOrange

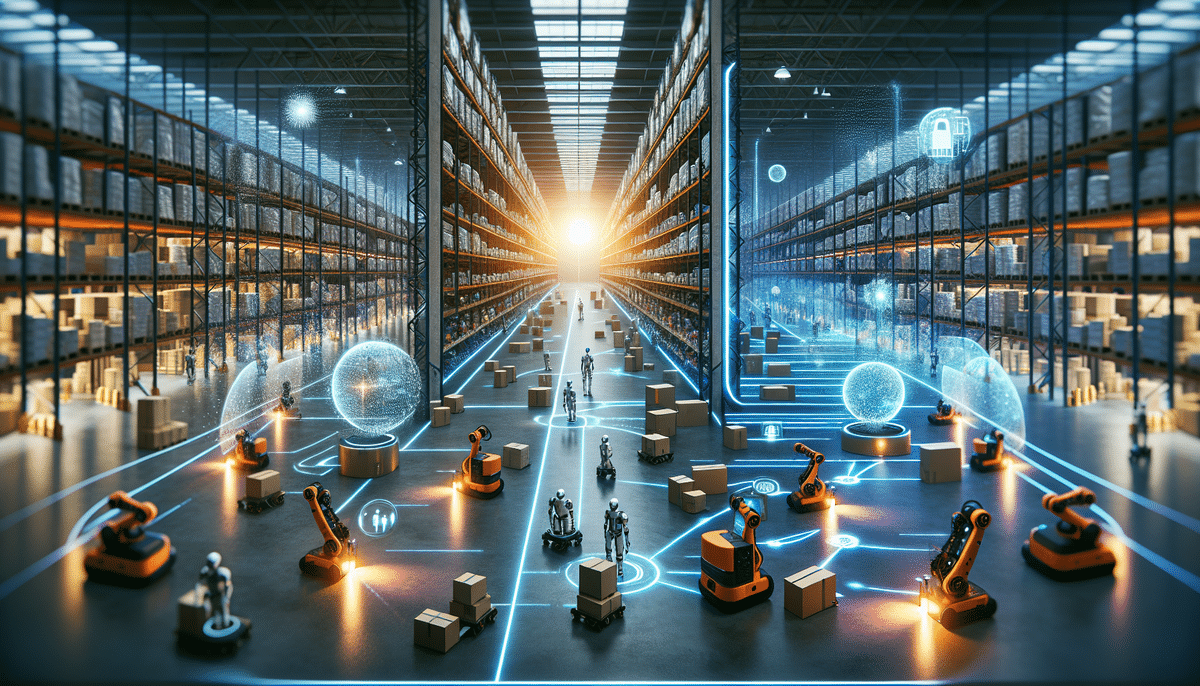

Locus Robotics' Collaborative Autonomous Mobile Robots (AMRs)

Locus Robotics utilizes a fleet of Autonomous Mobile Robots (AMRs) that operate alongside human workers in warehouses. These robots are equipped with state-of-the-art sensors, cameras, and machine learning algorithms, enabling them to efficiently handle, transport, and organize products. According to a Forbes report, Locus robots can increase picking rates by up to 200%, significantly enhancing warehouse productivity.

GreyOrange's GreyMatter AI and Automation Solutions

GreyOrange offers a comprehensive suite of automation solutions powered by its proprietary GreyMatter AI engine. This platform integrates various systems, including Goods-to-Person, Automated Sorting, and Orders-to-Bin technologies, facilitating extensive warehouse optimization. According to a Supply Chain 247 article, GreyMatter AI has been instrumental in reducing operational costs by up to 30% for large distribution centers.

Comparative Analysis of Technologies

While both companies aim to enhance warehouse efficiency, their approaches differ. Locus Robotics focuses on collaborative robots that seamlessly integrate with existing warehouse workflows, promoting synergy between humans and robots. In contrast, GreyOrange emphasizes a centralized AI-driven platform that optimizes various aspects of warehouse operations through automation.

Company Background and Market Presence

Locus Robotics: Growth and Partnerships

Founded in 2014 in Massachusetts, Locus Robotics has rapidly expanded its presence across North America, Europe, and Asia. Serving industry leaders like DHL, GEODIS, and Boots, Locus has secured partnerships with major investors such as Toyota and SoftBank, bolstering its position in the automation market.

GreyOrange: Global Expansion and Innovations

Established by Samay Kohli and Akash Gupta, GreyOrange has positioned itself as a global contender in warehouse automation. With over $170 million in funding, the company has deployed its solutions in diverse environments, catering to both small e-commerce warehouses and high-volume distribution centers globally.

Scalability and Cost-Benefit Analysis

Scalability of Locus Robotics Solutions

Locus Robotics offers scalable solutions, with the ability to deploy approximately five to six robots per day through their "plug and play" installation process. This rapid scalability makes it ideal for businesses experiencing significant growth or seasonal demand fluctuations.

GreyOrange's Scalable AI-Powered Systems

GreyOrange's systems are designed to be highly adaptable and scalable, allowing businesses to expand their automation capabilities in line with operational demands. This scalability is supported by the GreyMatter platform, which can handle increased order volumes without compromising efficiency.

Cost Analysis

The implementation costs for Locus Robotics typically involve an annual rental fee per robot, encompassing licensing, maintenance, and support. This model offers transparency and predictability in budgeting. GreyOrange, on the other hand, employs a custom pricing strategy tailored to each client's specific requirements, which can be advantageous for large-scale deployments but may require more negotiation.

Suitability for E-commerce Fulfillment

For businesses prioritizing a flexible solution that integrates seamlessly with current operations, Locus Robotics is highly suitable. Its collaborative robots enhance human workforce efficiency without necessitating a complete overhaul of existing systems. In contrast, GreyOrange's comprehensive AI-driven platform is better suited for high-volume warehouses seeking extensive automation across multiple operational facets.

Efficiency and Optimization in Warehouse Processes

Both Locus Robotics and GreyOrange significantly improve warehouse efficiency, albeit through different mechanisms. Locus Robotics enhances productivity by enabling multi-order picking and reducing manual errors through collaboration with human workers. GreyOrange utilizes data-driven AI to optimize inventory management, order fulfillment, and throughput, resulting in lower operational costs and increased accuracy.

Success Stories and Customer Satisfaction

Numerous e-commerce giants have reaped the benefits of implementing Locus Robotics and GreyOrange solutions. For instance, DHL reported a 25% increase in picking efficiency after deploying Locus robots. Similarly, GreyOrange's implementation at Zalando resulted in a 30% reduction in order processing time, showcasing the tangible benefits of warehouse automation.

Challenges in Implementing Warehouse Automation

Despite the advantages, deploying automated systems like Locus Robotics and GreyOrange can present challenges. High initial investment costs and the complexity of integrating new technologies into existing workflows are primary concerns. Additionally, there may be a learning curve for staff to adapt to new systems, necessitating training and change management strategies.

Future Impact on the Logistics Industry

The ongoing advancements in robotics and AI are set to revolutionize the logistics sector. According to a Gartner forecast, the global warehouse automation market is expected to reach $7 billion by 2025. Companies like Locus Robotics and GreyOrange are pivotal in driving this transformation, enabling more efficient, scalable, and intelligent warehouse operations.

Conclusion

Both Locus Robotics and GreyOrange offer robust solutions that cater to different aspects of warehouse automation. Locus Robotics excels in collaborative, easily deployable robot systems that enhance human productivity, while GreyOrange provides an AI-driven platform that offers comprehensive automation for large-scale and complex warehouse environments. Businesses must assess their unique operational needs, scalability requirements, and budget constraints to choose the solution that best aligns with their e-commerce fulfillment and warehouse management goals.