Knapp vs GreyOrange: Choosing the Right Automated Warehouse Solution for Your Business

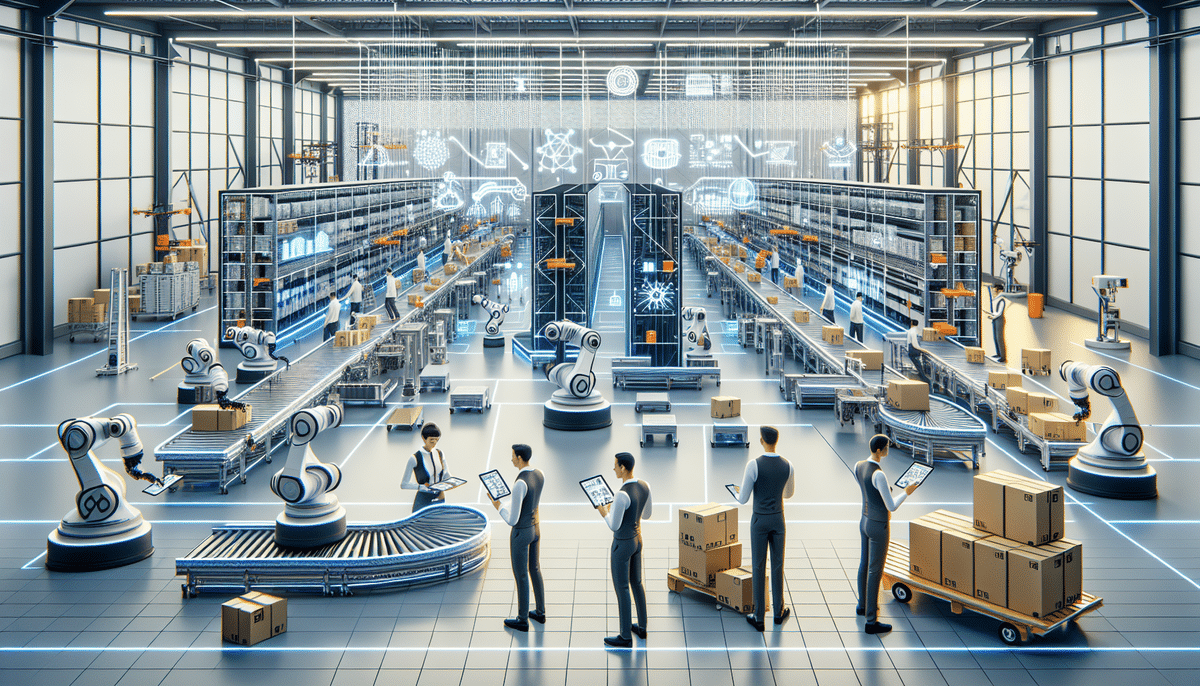

In the realm of automated warehouse solutions, Knapp and GreyOrange are renowned for their cutting-edge technology and efficient processes. Selecting the right system is crucial for optimizing your warehouse operations. This comprehensive comparison will guide you in making an informed decision tailored to your business needs.

Comprehensive Comparison of Knapp and GreyOrange

Overview

Knapp and GreyOrange both offer advanced automated warehouse systems, but they cater to different operational requirements and business sizes. Understanding their core functionalities and specializations is essential for determining which system aligns best with your organizational goals.

Technology Integration

Knapp integrates robotics, conveyor systems, and sophisticated software to enhance picking and packing operations. Their Automated Storage and Retrieval System (ASRS) ensures efficient storage and retrieval of goods, accommodating a wide range of product sizes.

GreyOrange, on the other hand, leverages AI-powered robots equipped with computer vision technology. Their systems are designed for tasks such as picking, sorting, and transportation, and seamlessly integrate with existing Warehouse Management Systems (WMS) to optimize workflow.

Both companies utilize artificial intelligence and IoT technologies to enhance operational efficiency and accuracy.

Implementation and Scalability

Knapp systems typically require a longer lead time for installation and customization due to their comprehensive nature. This makes them suitable for large-scale operations with specific needs.

GreyOrange's modular design allows for quicker and more flexible implementation, making it ideal for businesses that need to scale their operations rapidly or have variable demands.

Accuracy and Reliability

Knapp boasts an impressive accuracy rate of less than 0.1%, making it highly reliable for high-volume and diverse inventory management.

While GreyOrange also maintains high accuracy, its AI-driven systems continuously learn and improve, promising even greater precision over time. Occasional errors have been reported but are mitigated by ongoing system enhancements.

Advantages and Disadvantages

- Knapp

- Advantages: Highly efficient for large-scale operations, customizable for diverse product ranges, integrates seamlessly with various WMS.

- Disadvantages: Higher implementation costs, longer lead times, requires specialized expertise for maintenance.

- GreyOrange

- Advantages: Flexible and modular design, quicker implementation, AI-powered adaptability to changing business needs.

- Disadvantages: Initial implementation can be costly, may not be as effective for handling very large or bulky items, mixed feedback on customer support responsiveness.

Cost Analysis

The cost of implementing either a Knapp or GreyOrange system depends on various factors, including warehouse size, product volume, and specific customization requirements.

- Knapp: Generally involves higher upfront costs due to system complexity and extensive customization. However, long-term savings are realized through increased efficiency and reduced labor costs.

- GreyOrange: May have lower initial investment costs with modular components. Long-term expenses can include maintenance and upgrades of AI-powered robots.

It's essential to evaluate both the immediate and long-term financial implications to determine which system offers the best return on investment (ROI) for your business.

Case Studies: Successful Implementations

Both Knapp and GreyOrange have demonstrated their effectiveness through successful implementations across various industries:

- Knapp has partnered with global brands such as Adidas and Levi's, enhancing their warehouse operations and boosting efficiency.

- GreyOrange has collaborated with companies like Decathlon and Flipkart, optimizing their warehouse processes and increasing productivity.

- Additional collaborations include Knapp's work with BMW and Coca-Cola, leading to significant improvements in operational efficiency and accuracy.

- GreyOrange's implementations for Arvind Lifestyle Brands have resulted in increased throughput and reduced order processing times.

These case studies highlight the versatility and effectiveness of both Knapp and GreyOrange solutions in diverse real-world applications.

Choosing the Right System for Your Warehouse

Selecting between Knapp and GreyOrange requires a thorough assessment of your business's specific needs and objectives:

- Inventory Volume and Diversity: Knapp is ideal for businesses with large and diverse inventories, while GreyOrange suits those looking for flexible automation solutions.

- Warehouse Layout and Infrastructure: Evaluate how each system integrates with your existing warehouse layout and infrastructure.

- Budget Considerations: Assess both upfront and long-term costs, including implementation, maintenance, and potential upgrades.

- Customization and Flexibility: Determine the level of customization required. Knapp offers extensive customization, whereas GreyOrange provides more standardized yet adaptable solutions.

- Support and Maintenance: Consider the level of customer support and maintenance services provided by each vendor. Knapp is known for exceptional customer service, while GreyOrange has mixed reviews regarding support responsiveness.

Engaging with a warehouse automation consultant can offer personalized recommendations based on your specific operational requirements.

Future Trends in Automated Warehousing

The landscape of automated warehousing is rapidly evolving, with both Knapp and GreyOrange at the forefront of innovation. Emerging trends include:

- Advanced AI and Machine Learning: Enhanced AI algorithms for better decision-making and predictive analytics in warehouse management.

- Sustainability Initiatives: Implementation of eco-friendly solutions such as energy-efficient systems and sustainable packaging materials.

- Internet of Things (IoT) Integration: Greater connectivity through IoT devices and sensors for real-time monitoring and data analysis.

- Robotic Process Automation (RPA): Increased use of robotics for repetitive tasks, reducing human error and labor costs.

By embracing these trends, Knapp and GreyOrange aim to further enhance operational efficiency, reduce downtime, and improve overall productivity in automated warehouses.

Best Practices for Maximizing Efficiency

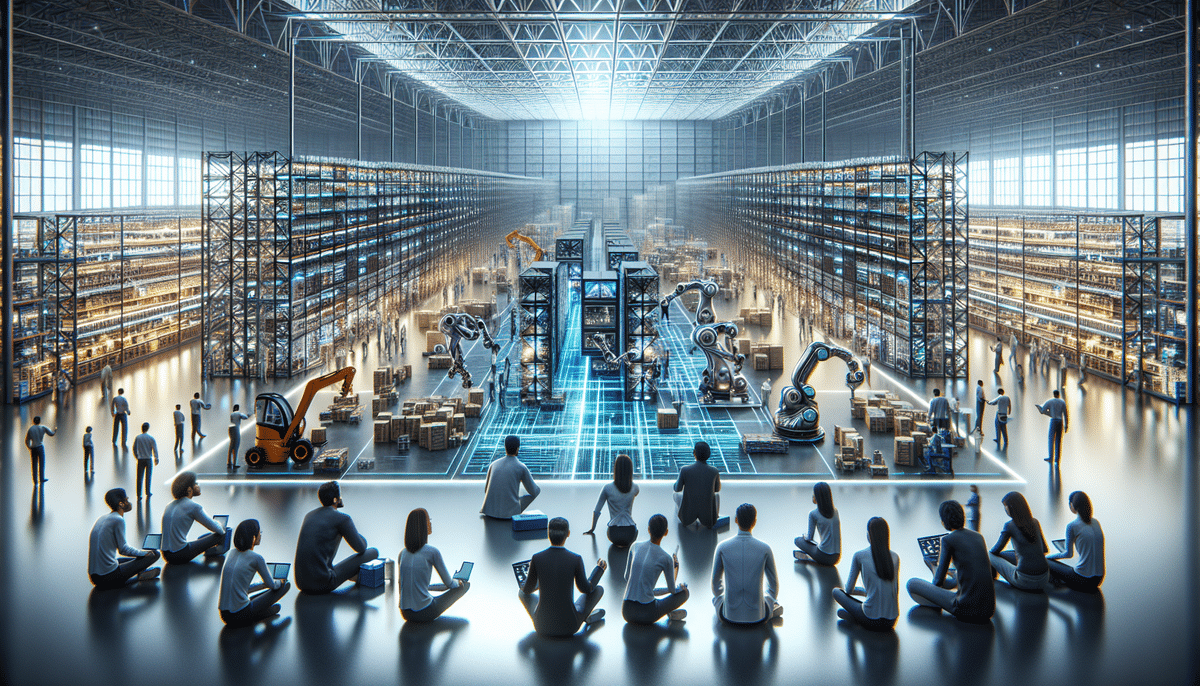

To ensure optimal performance and return on investment with Knapp or GreyOrange systems, consider implementing the following best practices:

- Regular Maintenance: Schedule routine maintenance to prevent system breakdowns and minimize downtime.

- Comprehensive Staff Training: Provide thorough training for staff to efficiently operate and manage the automated systems.

- Optimized Warehouse Layout: Design your warehouse layout to fully leverage the capabilities of the automated systems.

- Continuous Performance Monitoring: Use data analytics to monitor system performance and identify areas for improvement.

- Software Upgrades: Keep system software up to date to benefit from the latest features and security enhancements.

- Disaster Recovery Planning: Develop a comprehensive disaster recovery plan to maintain operations during unexpected events.

Implementing these best practices will ensure that your automated warehouse system operates efficiently, delivering sustained ROI and supporting your business growth.

Conclusion

Knapp and GreyOrange are both leading providers of automated warehouse solutions, each with distinct advantages tailored to different business needs. When deciding between these systems, it is essential to evaluate your specific operational requirements, budget constraints, and long-term strategic goals.

Consulting with a warehouse automation expert can provide valuable insights and help you select the most effective system for your operations. By choosing the right solution and adhering to best practices, you can ensure that your warehouse operates efficiently, enhances productivity, and delivers the desired return on investment.