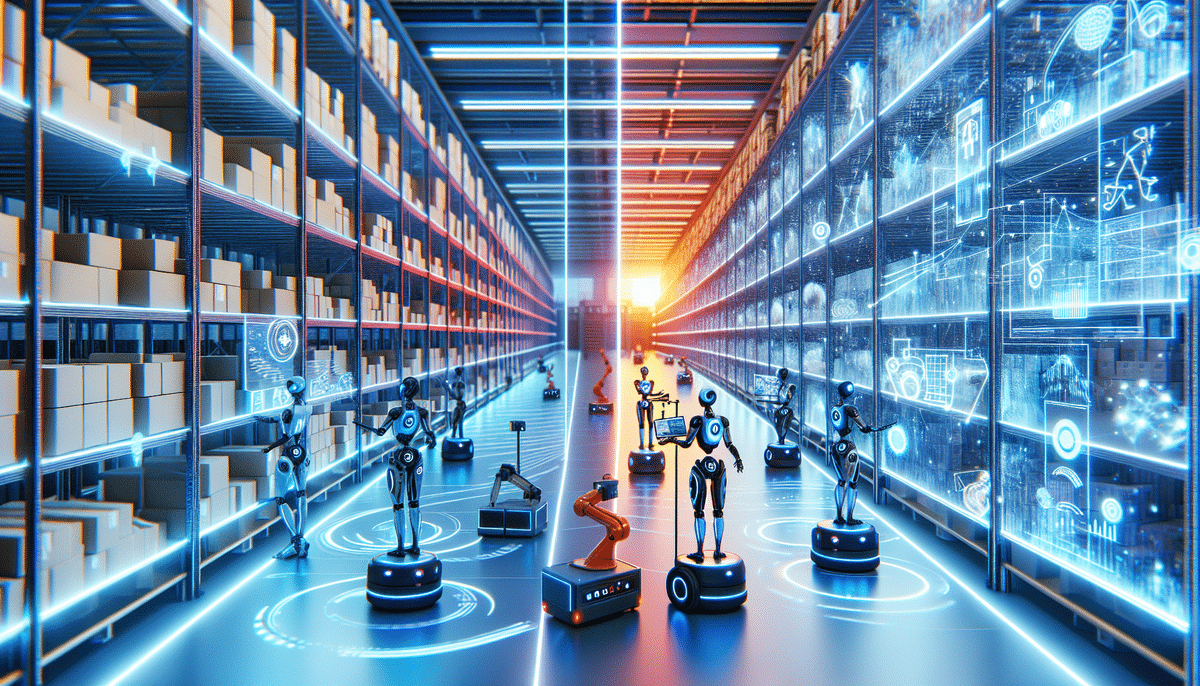

Introduction to Automated Warehouse Systems

Automated warehouse systems utilize advanced technologies such as robotics, artificial intelligence, and machine learning to manage and optimize the movement, storage, and retrieval of products within a warehouse. By integrating hardware, software, and robotics, these systems automate tasks like picking, packing, and shipping, resulting in increased efficiency, reduced labor costs, and minimized errors. Real-time inventory tracking allows businesses to monitor stock levels accurately and make informed reordering decisions, thereby reducing the risk of inventory discrepancies and ensuring timely order fulfillment (Supply Chain Digital).

Overview of 6 River Systems and Amazon Robotics

6 River Systems offers collaborative mobile robots and cloud-based software designed to enhance warehouse operations. Acquired by Shopify in 2019, it is now integrated into the Shopify Fulfillment Network (Shopify Fulfillment Network). Amazon Robotics, formerly known as Kiva Systems before Amazon’s acquisition in 2012, provides autonomous mobile robots and software aimed at optimizing warehouse operations for Amazon and other businesses.

Comparative Analysis: 6 River Systems vs. Amazon Robotics

Automation Approach

6 River Systems utilizes collaborative robots, or "cobots," that work alongside human workers to enhance efficiency and productivity without fully replacing the human workforce. This approach fosters a synergistic environment where humans and robots complement each other.

Amazon Robotics employs fully autonomous robots that operate independently to manage large volumes of inventory with minimal human intervention. This method is highly efficient for large-scale operations but may require significant changes to existing workflows (Forbes).

Customization and Flexibility

6 River Systems offers greater customization, allowing businesses to adapt the system to diverse warehouse layouts and workflows. This flexibility makes it suitable for various industries and operational scales. In contrast, Amazon Robotics provides a highly efficient solution optimized for specific warehouse configurations, particularly those of Amazon, but may require substantial modifications to a warehouse's layout and processes.

Key Features of 6 River Systems

- Easy setup and deployment

- Intuitive software with real-time visibility

- Cloud-based integration with existing systems

- Scalability and flexibility

- Real-time data insights for informed decision-making

6 River Systems' adaptive robots can be reconfigured to fit new layouts or changes in product inventory, enhancing efficiency and productivity. The user-friendly interface ensures that workers can interact seamlessly with the robots, reducing the need for extensive training and increasing overall worker satisfaction.

Key Features of Amazon Robotics

- Autonomous robots for inventory movement

- Centralized control software for streamlined management

- Rapid setup and deployment

- Flexible and scalable solutions

- Data-driven insights to optimize operations

Amazon Robotics significantly reduces the time and labor required for order fulfillment by automating inventory movement. This automation leads to faster and more accurate processing of orders, resulting in higher customer satisfaction and increased repeat business. The system's scalability ensures that it can grow with your business, adapting to expanding inventory and evolving operational requirements without the need for a complete overhaul.

Advantages and Disadvantages

6 River Systems

Advantages

- Ease of use and deployment

- Collaborative robots working alongside human operators

- Real-time visibility and data insights

- Scalable and flexible solution

Disadvantages

- Limited carrying capacity of collaborative robots

- May not be ideal for high-volume warehouses

- Higher initial implementation costs

Amazon Robotics

Advantages

- Autonomous robots with higher inventory handling capacity

- Quick setup and deployment

- Centralized control for easy management

- Valuable data insights for decision-making

Disadvantages

- High upfront costs

- Less flexibility compared to other solutions

- Requires significant changes to warehouse layout and processes

Both systems offer robust automation capabilities, but each comes with its own set of strengths and limitations. 6 River Systems is ideal for businesses seeking flexibility and collaboration between humans and robots, while Amazon Robotics excels in large-scale, high-volume operations requiring autonomous solutions.

Factors to Consider When Choosing an Automated Warehouse System

- Cost: Evaluate both upfront and ongoing expenses to ensure the solution fits within your budget.

- Scalability: Ensure the system can grow with your business needs.

- Capacity: Choose a system that can handle your current and projected inventory volumes.

- Customization: Verify that the system can be tailored to your specific warehouse layout and workflows.

- Integration: Ensure seamless integration with your existing systems.

Additionally, consider the level of maintenance and support provided by the vendor. Reliable support is essential for addressing issues promptly and ensuring the system operates smoothly. Training and education provided by the vendor are also critical, as a well-trained staff is necessary to effectively manage and utilize the automated system (Logistics Management).

Use Cases for 6 River Systems and Amazon Robotics

6 River Systems:

- Assisting a growing US-based e-commerce company in doubling its daily shipments within six months.

- Enhancing order processing time by 80% for a Canadian apparel distributor.

- Reducing carton count by 47% for a global footwear retailer in Brazil.

Amazon Robotics:

- Optimizing warehouse operations for Amazon, managing millions of daily shipments efficiently.

- Increasing order processing speed by fourfold for a major toy retailer in the UK.

- Decreasing damaged goods and associated costs for a US-based kitchenware manufacturer.

Innovations and the Future of Automated Warehouses

The advancement of technologies such as artificial intelligence, machine learning, and predictive analytics continues to enhance the capabilities of automated warehouse systems. These innovations enable more sophisticated inventory management, predictive maintenance, and adaptive learning systems that further optimize warehouse operations (Forbes Technology Council).

The future of automated warehousing looks promising, with ongoing investments in technology driving further improvements in efficiency and productivity. As machines and software become more advanced, warehouse management will increasingly rely on intelligent automation, leading to smarter, more responsive, and highly efficient operations.

Conclusion: Making the Right Choice for Your Business

Choosing the right automated warehouse system is a pivotal decision that depends on your business's unique requirements and objectives. Both 6 River Systems and Amazon Robotics offer advanced solutions capable of transforming warehouse operations. By carefully considering factors such as cost, scalability, capacity, customization, and integration, you can make an informed decision that aligns with your business goals and ensures long-term success.