Introduction

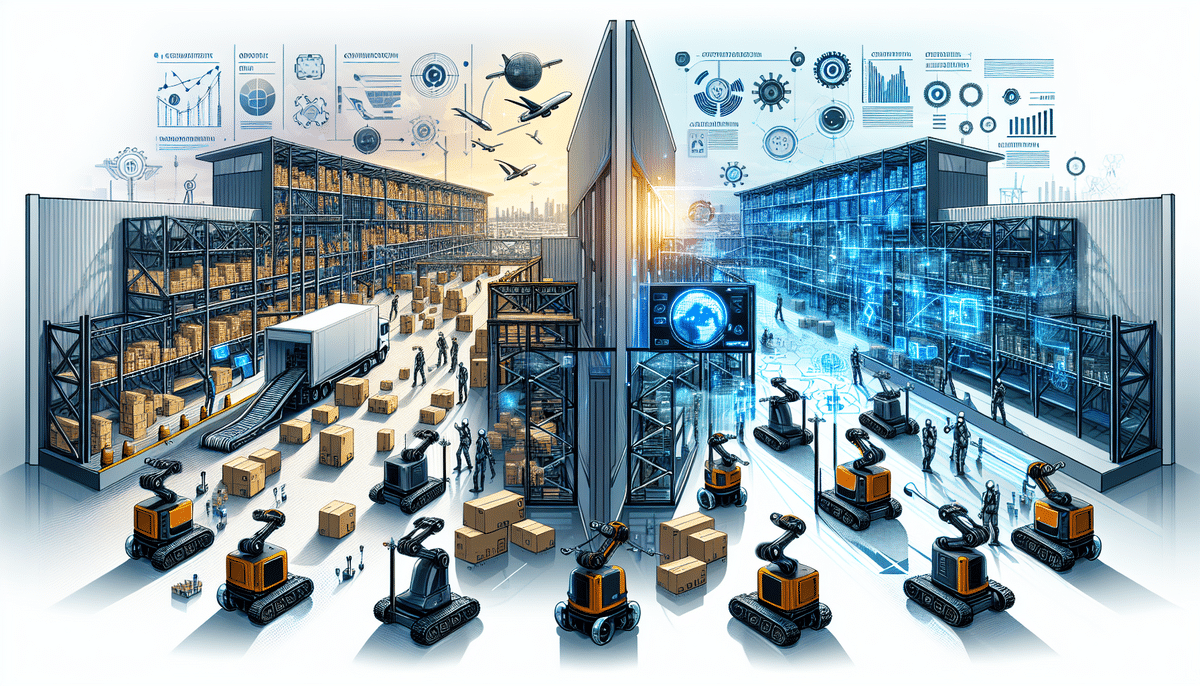

In the realm of warehouse automation, Knapp and Fetch Robotics stand out as prominent players offering innovative robotic solutions. This article provides a comprehensive comparison of these two companies, delving into their products, services, and overall impact on warehouse efficiency to help businesses identify the best fit for their operational needs.

Overview of Knapp

Knapp is an Austrian company with over seven decades of experience in logistics automation. They specialize in designing and implementing customized automation systems for various industries, including healthcare, retail, and fashion. Knapp's solutions focus on optimizing warehouse processes, reducing operational costs, and enhancing efficiency through advanced technologies such as automated storage and retrieval systems (AS/RS), conveyor systems, and shuttle systems.

Overview of Fetch Robotics

Fetch Robotics, established in 2014, is a leading innovator in autonomous mobile robots (AMRs) designed to streamline warehouse operations. Their robots are engineered to collaborate seamlessly with human workers, performing tasks like picking, transporting, and inventory management. Equipped with state-of-the-art sensors and AI-driven navigation systems, Fetch Robotics' AMRs enhance flexibility and scalability in dynamic warehouse environments.

Key Differences Between Knapp and Fetch Robotics

Scope of Solutions

Knapp provides end-to-end automation solutions encompassing a wide range of systems, including AS/RS, conveyor belts, and sophisticated software integrations. Their comprehensive approach caters to diverse industry needs, offering highly customizable systems tailored to specific operational requirements.

Customization and Flexibility

While Knapp focuses on comprehensive, highly customized automation systems, Fetch Robotics emphasizes flexibility and scalability with their AMRs. Fetch's solutions are designed to be easily configurable for various tasks without necessitating extensive overhauls of existing warehouse infrastructure.

Industry Focus

Knapp serves a broad spectrum of industries such as healthcare, food & beverage, retail, and fashion, providing specialized automation solutions for each. In contrast, Fetch Robotics primarily targets the logistics and warehousing sectors, offering solutions that enhance efficiency in material handling and order fulfillment.

Cost Comparison

Initial Investment

Knapp's comprehensive automation systems typically involve a higher initial investment due to their extensive customization and integration capabilities. These systems are designed for large-scale operations, where the upfront costs are offset by long-term gains in efficiency and reduced labor costs.

Maintenance Costs

Fetch Robotics offers a more cost-effective entry point with lower initial costs. However, businesses should consider ongoing maintenance and potential scalability requirements, which could influence the overall cost-benefit analysis.

Scalability

Knapp's solutions are ideal for large-scale operations with plans for expansion, offering robust systems that can be scaled effectively. On the other hand, Fetch Robotics provides scalable AMRs that can be easily added or reconfigured to meet evolving operational demands, making them suitable for businesses anticipating growth or fluctuating workloads.

According to a Forbes analysis, implementing warehouse automation can lead to up to a 20% increase in efficiency, justifying the investment over time.

Functional and Performance Analysis

Automation Levels

Knapp’s systems provide a high level of automation, suitable for handling large volumes and diverse product types. Their AS/RS and conveyor systems minimize the need for manual intervention, thereby enhancing operational efficiency and reducing error rates.

Software and Integration

Both Knapp and Fetch Robotics offer advanced software solutions. Knapp’s software enables real-time inventory tracking and predictive analytics, integrating seamlessly with existing Warehouse Management Systems (WMS). Fetch Robotics also provides robust software that facilitates the integration of their AMRs with WMS, offering detailed performance metrics and operational insights.

Operational Efficiency

Knapp’s comprehensive automation reduces operational bottlenecks, leading to increased throughput and lower operational costs. Fetch Robotics’ AMRs enhance flexibility by allowing for quick task reassignments and adaptive workflows, making warehouses more responsive to changing demands.

A McKinsey report highlights the significant role of robotics and AI in driving warehouse efficiency, indicating that both Knapp and Fetch Robotics are well-positioned to leverage these advancements.

Pros and Cons

Pros of Knapp

- Highly customizable solutions tailored to specific business needs.

- Comprehensive systems with a high degree of automation.

- Robust and reliable systems capable of handling large volumes and diverse types of goods.

Cons of Knapp

- Higher initial investment compared to Fetch Robotics' AMRs.

- Less flexibility and scalability for smaller operations.

- Complex systems that may require extensive training to operate.

Pros of Fetch Robotics

- Flexible and scalable solutions ideal for smaller warehouses or dynamic operations.

- User-friendly AMRs that require minimal training to operate.

- Cost-effective entry into warehouse robotics compared to comprehensive systems.

Cons of Fetch Robotics

- Less comprehensive automation, potentially requiring additional equipment for end-to-end solutions.

- May not be suitable for very large warehouses or those with highly complex operations.

- AMRs might struggle with handling larger and heavier items efficiently.

Both Knapp and Fetch Robotics offer robust solutions, but the optimal choice depends on factors such as warehouse size, types of goods handled, required level of automation, and budget constraints.

Choosing the Right Solution for Your Business

Selecting between Knapp and Fetch Robotics hinges on your warehouse's specific needs and operational objectives. If your facility is large-scale with complex operations and you have the budget for a comprehensive automation system, Knapp’s solutions offer extensive customization, high automation levels, and robust support, making them suitable for long-term scalability and efficiency.

Conversely, if your warehouse is smaller, requires operational flexibility, and operates with a limited budget, Fetch Robotics' AMRs provide an ideal solution. Their robots are easy to deploy, require minimal training, and can be quickly adapted to various tasks, offering immediate improvements in productivity and operational agility.

Additionally, consider the technical expertise of your team. Knapp's systems may require more specialized knowledge to operate and maintain, whereas Fetch Robotics' AMRs are designed for user-friendliness and ease of integration.

For further insights, refer to Supply Chain Dive's guide on selecting the right warehouse automation partner.

The Future of Robotics in Warehousing

The future of warehouse robotics is poised for significant advancements, with ongoing innovations set to revolutionize the industry. Both Knapp and Fetch Robotics are at the forefront of this transformation, continually enhancing their technologies to meet evolving market demands.

Knapp is advancing with technologies like augmented reality-guided picking systems, which streamline the picking process and reduce human error. Their focus on integrating comprehensive automation with advanced software analytics positions them as leaders in end-to-end warehouse solutions.

Fetch Robotics is enhancing their offerings with AI-powered systems that enable their AMRs to learn and adapt in real-time, increasing their effectiveness and versatility in dynamic warehouse environments. This adaptability is crucial as warehouses become more complex and demand more flexible automation solutions.

One of the key benefits of robotics in warehousing is the reduction of workplace injuries. By automating heavy lifting and repetitive tasks, robots allow human workers to focus on more strategic and less physically demanding activities, thereby reducing the risk of strain injuries and accidents.

Moreover, robots can operate around the clock, significantly increasing productivity without the limitations of human work hours. As the demand for faster and more efficient warehousing solutions grows, the adoption of robotics is expected to accelerate, further driving innovations from companies like Knapp and Fetch Robotics.

According to the Forbes Technology Council, the integration of robotics and AI will continue to shape the future of warehousing, making operations more intelligent, efficient, and resilient.