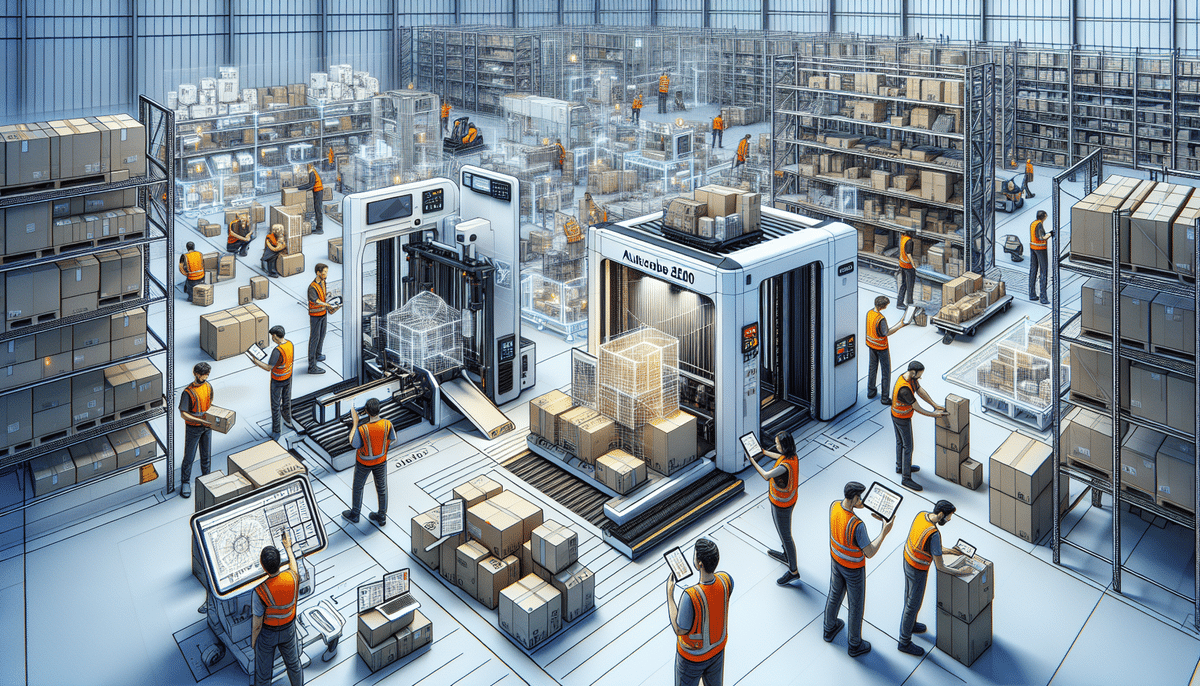

Introduction to Dimensioning Systems: Honeywell AutoCube 8200 vs FreightSnap

Choosing the right dimensioning system is crucial for optimizing your business operations. Two leading options in the market today are the Honeywell AutoCube 8200 and FreightSnap. This comprehensive comparison will help you determine which system best aligns with your business needs, considering factors such as accuracy, speed, ease of use, and cost-effectiveness.

Overview of Honeywell AutoCube 8200 and FreightSnap

The Honeywell AutoCube 8200 and FreightSnap are state-of-the-art dimensioning solutions designed to measure and weigh freight efficiently. These systems leverage advanced technologies to capture precise dimensions, enabling businesses to reduce shipping costs and enhance operational efficiency.

- Honeywell AutoCube 8200: Utilizes 3D depth sensing technology for accurate measurements of irregularly shaped objects.

- FreightSnap: Employs laser measurement technology with a variety of device options, offering flexibility for different measurement scenarios.

According to a Frost & Sullivan report, the global market for dimensioning systems is expected to grow by 6.5% annually, highlighting the increasing importance of accurate freight measurement in logistics.

Key Features Comparison

Both Honeywell AutoCube 8200 and FreightSnap offer a range of features that cater to diverse business needs:

Honeywell AutoCube 8200 Features

- High-resolution 3D depth-sensing camera

- Real-time dimension calculation with ±2mm accuracy

- Concurrent processing of up to four scans simultaneously

- Intuitive user interface with seamless integration capabilities

- Image capture for visual documentation and quality control

FreightSnap Features

- Multiple device options: stationary, mobile, and handheld

- Laser range technology with ±1/8” accuracy

- Proprietary software for comprehensive data management

- Customizable reporting and analytics for shipping insights

- Automation features to streamline shipping processes

FreightSnap's ability to offer various device types makes it adaptable to different operational environments, while Honeywell's AutoCube 8200 stands out with its high precision and multi-object scanning capabilities.

Accuracy and Performance

Accuracy is paramount in dimensioning systems to ensure consistent shipping costs and operational efficiency:

- Honeywell AutoCube 8200: Delivers ±2mm accuracy, ideal for businesses requiring meticulous measurement of irregularly shaped packages.

- FreightSnap: Provides ±1/8” accuracy, suitable for a broad range of applications with standard shipping requirements.

Environmental factors such as lighting, surface reflectivity, and object geometry can influence measurement accuracy. The Honeywell AutoCube 8200 incorporates adaptive technology to maintain precision in various conditions, whereas FreightSnap's software is designed to automatically adjust for irregular shapes, enhancing reliability.

According to a study by Supply Chain Dive, businesses that implement accurate dimensioning systems can reduce shipping costs by up to 20%, underscoring the importance of precision in these solutions.

Speed and Efficiency

Operational efficiency is driven by how quickly and accurately freight is measured:

- Honeywell AutoCube 8200: Capable of measuring up to four items simultaneously, with each scan completed in 3-5 seconds.

- FreightSnap: Offers varying measurement speeds depending on the device type, with stationary units optimized for high-throughput environments.

FreightSnap's mobile devices enhance flexibility for businesses operating across multiple locations or handling large items, while Honeywell's faster multi-object scanning ensures rapid processing in busy warehouses.

Ease of Use and Integration

User-friendliness and seamless integration with existing systems are critical for minimizing training time and maximizing productivity:

- Honeywell AutoCube 8200: Features an intuitive interface and a high-resolution camera, facilitating easy operation with minimal training.

- FreightSnap: Provides robust software with extensive customization options, which may require more comprehensive training but offers greater flexibility and functionality.

Integration capabilities are essential for businesses looking to streamline their workflows. Honeywell AutoCube 8200 offers straightforward integration with major warehouse management systems, while FreightSnap's proprietary software allows for extensive customization to fit specific business processes.

Pricing and Total Cost of Ownership

Budget considerations play a significant role in selecting a dimensioning system:

- Honeywell AutoCube 8200: Priced around $15,000, positioning it in the mid-range market segment. Offers a pay-per-use software model, providing flexibility based on usage patterns.

- FreightSnap: Devices range from $2,000 to $10,000, catering to various budget levels. The proprietary software includes a subscription fee starting at $50 per month.

When calculating the total cost of ownership, businesses should consider not only the initial investment but also ongoing software costs, maintenance, and potential scalability needs. According to Inbound Logistics, investing in a scalable solution can lead to long-term savings and operational efficiencies.

Customer Reviews and Feedback

Real-world user experiences provide valuable insights into the performance and usability of these dimensioning systems:

- Honeywell AutoCube 8200: Users commend its high accuracy, efficiency, and ease of use. The ability to scan multiple boxes simultaneously is frequently highlighted as a significant advantage.

- FreightSnap: Customers appreciate the flexibility and variety of device options. Some users mention that the software has a steeper learning curve compared to Honeywell AutoCube 8200, but it offers powerful customization once mastered.

Overall, both systems receive positive feedback for their accuracy and efficiency, with Honeywell AutoCube 8200 being favored for its straightforward user interface and FreightSnap for its versatile device offerings.

Pros and Cons

Honeywell AutoCube 8200

- Pros:

- High accuracy in dimensioning

- Fast scanning with multi-object capabilities

- User-friendly interface requiring minimal training

- Flexible integration with existing systems

- Cons:

- Higher mid-range price point

- Limited mobile measurement capabilities

- Requires a certain level of IT proficiency for software management

FreightSnap

- Pros:

- Cost-effective solutions across various device types

- Multiple measurement options catering to different needs

- Customizable reporting and data management

- Automation of shipping processes enhances efficiency

- Cons:

- Accuracy levels may vary based on device type

- Software can be complex, requiring extensive training

- Additional subscription costs for proprietary software

How to Choose the Right Dimensioning System for Your Business

Selecting the appropriate dimensioning system involves evaluating several key factors:

- Accuracy: Assess the level of precision required for your shipments to ensure cost-effective shipping.

- Speed: Determine how quickly you need to measure shipments to maintain operational efficiency.

- Ease of Use: Consider the technical proficiency of your staff and the training required for each system.

- Cost: Balance your budget with the features and scalability offered by each solution.

- Integration: Ensure the system can seamlessly integrate with your existing workflows and software platforms.

By carefully analyzing these factors, you can make an informed decision on whether Honeywell AutoCube 8200 or FreightSnap is the better fit for your dimensioning needs.

Conclusion: Making the Right Choice for Your Business

The decision between Honeywell AutoCube 8200 and FreightSnap ultimately depends on your business's specific requirements. If your operations demand high accuracy, the ability to scan multiple items simultaneously, and an intuitive user interface, the Honeywell AutoCube 8200 is an excellent choice. On the other hand, if you prioritize flexibility with various device options, customizable reporting, and a more budget-friendly solution, FreightSnap may be more suitable.

Both systems offer robust solutions for accurate and efficient dimensioning, contributing to reduced shipping costs and enhanced operational workflows. Carefully assess your business needs, budget constraints, and desired features to select the system that best aligns with your objectives.

Additional Resources

For more information on selecting the right dimensioning system for your business, visit the ConfigIT blog on dimensioning systems.