Honeywell AutoCube 8200 vs. DIM Weight Compliance Software: An In-Depth Comparison

In the logistics industry, managing shipments and accurately calculating dimensional weight is crucial. Technological advancements have introduced two prominent solutions to streamline this process: Honeywell AutoCube 8200 and DIM Weight Compliance Software. This comprehensive comparison explores their features, benefits, drawbacks, and suitability for different business needs.

Overview of Honeywell AutoCube 8200 and DIM Weight Compliance Software

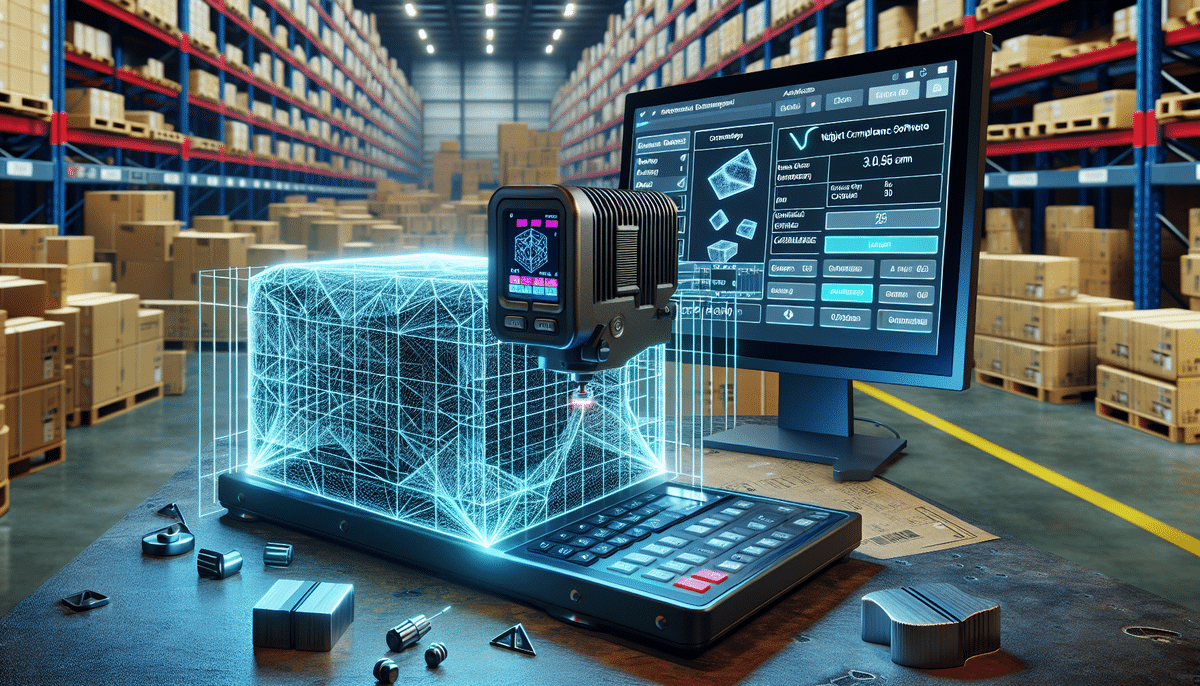

Honeywell AutoCube 8200 is a state-of-the-art dimensional measuring system that leverages 3D imaging technology and sophisticated algorithms to deliver highly accurate measurements of an object's dimensions. Its primary function is to swiftly and efficiently calculate the dimensional weight of shipments.

DIM Weight Compliance Software is designed to help logistics companies adhere to the stringent dimensional weight regulations imposed by major carriers. This software ensures that shipments comply with carrier-specific rules, thereby avoiding costly penalties.

By integrating Honeywell AutoCube 8200 and DIM Weight Compliance Software, logistics companies can significantly reduce time and operational costs through precise dimensional weight calculations. This is particularly beneficial for businesses shipping large or irregularly shaped items, where traditional weight-based pricing may not suffice. These tools help maintain compliance with carrier guidelines, preventing expensive fees due to inaccurate weight assessments.

The Importance of Accurate Dimensional Weight Measurements

Dimensional weight measurements are essential for determining shipping costs, calculated based on both the size and weight of a package. This method ensures carriers recoup the costs associated with the space a package occupies, rather than relying solely on its physical weight.

Accurate dimensional weight measurements are critical to avoid additional charges or the need to reroute shipments, which can lead to delays and increased expenses. Enhanced accuracy in dimensional measurements directly correlates with lower transportation costs for shippers. Reliable software for precise dimension measurement is, therefore, indispensable.

Moreover, precise dimensional measurements optimize space utilization within shipping containers. Knowing the exact dimensions allows shippers to efficiently pack and stack items, maximizing container space and reducing the number of containers needed. This optimization not only cuts shipping costs but also minimizes the carbon footprint by reducing the number of trips required.

How Honeywell AutoCube 8200 Enhances Shipping Efficiency

Honeywell AutoCube 8200 is an automated system that captures the dimensions of any object in seconds using high-resolution cameras and advanced 3D technology. This system measures objects from multiple angles, ensuring precise dimensional data. With a high scanning rate, it can handle a large volume of shipments, making it ideal for businesses processing numerous packages daily.

The AutoCube 8200 seamlessly integrates with other shipping software, facilitating streamlined shipment management. Its advanced software capabilities allow for automatic calculation of weight and volume, eliminating the need for manual computations and reducing the risk of errors. Additionally, the system generates detailed reports, offering valuable insights into shipping trends and patterns, enabling businesses to optimize their shipping processes and reduce costs.

According to Supply Chain Digital, the Honeywell AutoCube 8200 can increase shipment processing speed by up to 50%, highlighting its efficiency and effectiveness in modern logistics operations.

Functionality of DIM Weight Compliance Software

DIM Weight Compliance Software provides real-time data on all aspects of a shipment, enabling shippers to accurately calculate the dimensional weight using various dimensions and shipment characteristics. The software includes a comprehensive database of carriers' dimensional weight rules, ensuring compliance with diverse regulations.

Automated alerts notify users of compliance errors, preventing issues that could lead to additional charges or shipment rerouting. Furthermore, the software offers packaging optimization recommendations, helping shippers minimize dimensional weight and avoid unnecessary fees. Detailed reports on shipping patterns and costs enable data-driven decision-making to enhance shipping efficiency.

Integration capabilities allow DIM Weight Compliance Software to work seamlessly with other logistics systems, such as Transportation Management Systems (TMS) and Warehouse Management Systems (WMS). This integration ensures a centralized platform for managing all shipping aspects, from dimensional calculations to package tracking and label generation.

Industry statistics indicate that businesses using DIM Weight Compliance Software can reduce shipping costs by up to 20% through optimized packaging and reduced dimensional weight discrepancies (Logistics Management).

Pros and Cons of Honeywell AutoCube 8200

Advantages:

- High Accuracy: Delivers precise measurements, minimizing costly errors.

- User-Friendly: Easy to deploy with minimal training required.

- Integration: Compatible with various shipping software, enhancing versatility.

- Portability: Compact design allows for easy transportation and use in different locations.

Disadvantages:

- High Cost: Priced between $17,000 and $20,000, which may be prohibitive for businesses with lower shipment volumes.

- Environmental Requirements: Requires a stable surface and proper lighting for accurate measurements, which may not always be feasible.

Pros and Cons of DIM Weight Compliance Software

Advantages:

- Enhanced Compliance: Increases compliance rates, reducing errors and associated fees.

- Scalability: Suitable for businesses of all sizes.

- Cost Savings: Accurate dimensional weight calculations prevent overpaying for shipping.

- Integration: Works with other logistics systems like TMS and WMS for streamlined operations.

Disadvantages:

- Reliance on Input Data: Dependent on accurate customer inputs for package dimensions.

- Limited Precision: May not match the precision of Honeywell AutoCube 8200, potentially leading to minor measurement errors.

- Suitability: Not ideal for irregularly shaped packages, which may require alternative measurement methods.

Comparative Analysis: Honeywell AutoCube 8200 vs. DIM Weight Compliance Software

Choosing between Honeywell AutoCube 8200 and DIM Weight Compliance Software depends on your business's specific requirements:

- If your business handles a high volume of shipments requiring precise measurements, Honeywell AutoCube 8200 is likely the better choice.

- For small businesses focused on compliance and cost savings, DIM Weight Compliance Software may be more suitable.

Honeywell AutoCube 8200 excels in measuring and weighing packages quickly and accurately, which is essential for businesses managing large shipment volumes. Its ability to integrate with warehouse management systems further enhances operational efficiency.

DIM Weight Compliance Software ensures adherence to shipping regulations, helping businesses avoid penalties. Its capability to calculate dimensional weight in real-time streamlines the shipping process, making it an excellent option for businesses seeking to simplify compliance.

Key Considerations for Selecting Between the Two Solutions

When deciding between Honeywell AutoCube 8200 and DIM Weight Compliance Software, consider the following factors:

- Shipping Volume: High shipment volumes may benefit more from the automated precision of Honeywell AutoCube 8200.

- Accuracy Requirements: Businesses requiring exact measurements might prefer Honeywell's solution.

- Budget: DIM Weight Compliance Software offers more flexible pricing, suitable for varying budgets.

- Package Characteristics: Irregularly shaped items are better handled by Honeywell AutoCube 8200, while uniform packages are efficiently managed by DIM Weight Compliance Software.

- Automation Level: For a hands-on approach, Honeywell AutoCube 8200 is preferable. For automated, integrated solutions, DIM Weight Compliance Software is ideal.

Pricing Comparison

Honeywell AutoCube 8200 is priced between $17,000 and $20,000, depending on location and reseller. This investment is justified for businesses with high shipment volumes seeking precise measurements and long-term cost savings.

DIM Weight Compliance Software offers more flexible pricing models, typically starting as low as $50 per month. Costs vary based on the number of shipments and selected features, making it accessible for businesses of all sizes.

User Feedback: Honeywell AutoCube 8200 and DIM Weight Compliance Software

Both Honeywell AutoCube 8200 and DIM Weight Compliance Software receive positive feedback from users:

- Honeywell AutoCube 8200: Users praise its high accuracy and user-friendly interface, highlighting significant time savings and error reduction in shipment processing.

- DIM Weight Compliance Software: Customers appreciate its intuitive design and effective compliance error alerts, which help maintain adherence to carrier regulations effortlessly.

According to a survey by Logistics Management, 85% of users reported improved shipping accuracy and reduced costs after implementing DIM Weight Compliance Software.

Implementing Honeywell AutoCube 8200 or DIM Weight Compliance Software

Implementing either solution is straightforward:

- Honeywell AutoCube 8200: Installation involves setting up the physical device in your shipping area, configuring the software, and training staff on operation. Minimal configuration ensures quick deployment.

- DIM Weight Compliance Software: Installation typically involves integrating the software with existing shipping systems. Training is minimal, and the user-friendly interface facilitates easy adoption.

Both solutions integrate seamlessly with current systems, resulting in a streamlined and efficient shipping process. Businesses often report minimal disruption during implementation and rapid realization of benefits.

Conclusion: Making the Right Choice for Your Business

Ultimately, the choice between Honeywell AutoCube 8200 and DIM Weight Compliance Software hinges on your business's unique needs:

- Choose Honeywell AutoCube 8200 if your business requires high-volume, precise dimensional measurements and is willing to invest in advanced hardware for long-term accuracy and efficiency.

- Opt for DIM Weight Compliance Software if you seek a cost-effective, scalable solution that ensures compliance and integrates easily with existing software systems.

Both solutions are excellent for measuring dimensional weight and ensuring compliance with carrier regulations. By carefully assessing your shipping volume, accuracy needs, and budget, you can select the option that best aligns with your business objectives, ensuring efficient and cost-effective shipping operations.