Introduction to Warehouse Robotics: GreyOrange vs. Locus Robotics

In the world of warehousing, robotics has revolutionized the way companies manage their inventory. Two of the leading players in the market are GreyOrange and Locus Robotics. Both companies leverage cutting-edge technology to enhance warehouse efficiency, but there are key differences between the two. In this article, we provide an in-depth analysis of GreyOrange and Locus Robotics, comparing their features, benefits, and pricing models to help you decide which one is the best fit for your business.

Company Backgrounds

GreyOrange

GreyOrange is a Singapore-based company that offers automated solutions for warehousing, logistics, and supply chain management. Founded in 2011 by Indian engineers Samay Kohli and Akash Gupta, GreyOrange's flagship product is the Butler system, which utilizes robotics and artificial intelligence to optimize warehouse operations.

Locus Robotics

Locus Robotics, a US-based company founded in 2014 by Rick Faulk, specializes in collaborative autonomous mobile robots for warehouse fulfillment. Known for its innovative technology, Locus Robotics enables robots to work alongside human workers, significantly boosting productivity.

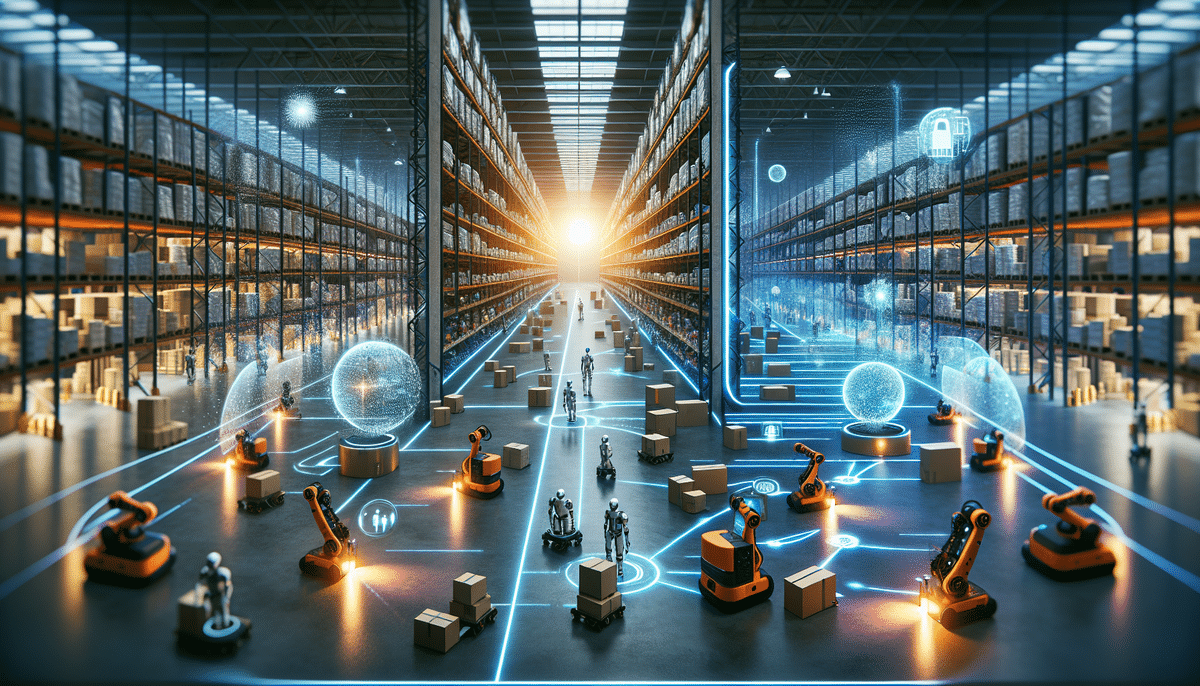

Technological Innovations

GreyOrange's Butler System

GreyOrange's Butler system integrates artificial intelligence, machine learning, and computer vision to streamline warehouse operations. These mobile robots navigate warehouse floors, pick items, and transport them to designated locations. The system seamlessly integrates with various warehouse management systems, optimizing inventory management, order picking, and sorting.

Locus Robotics' Collaborative Robots

Locus Robotics employs collaborative autonomous mobile robots (AMRs) designed to fit into existing warehouse infrastructures. These robots work alongside human employees, performing tasks such as picking items from shelves, transporting them, and scanning barcodes to confirm deliveries. Equipped with advanced sensors and algorithms, Locus's robots navigate complex environments, adapt to changes, and optimize their routes to enhance efficiency.

Key Differences Between GreyOrange and Locus Robotics

Autonomous vs. Collaborative Systems

GreyOrange's Butler system offers a fully autonomous solution requiring minimal human intervention, utilizing AI and computer vision to coordinate operations efficiently. In contrast, Locus Robotics provides collaborative robots that work in tandem with human workers, offering greater flexibility and adaptability to dynamic warehouse needs.

Industry Focus

GreyOrange targets large-scale warehouses and distribution centers across industries like e-commerce, retail, and manufacturing. Locus Robotics primarily focuses on the e-commerce and retail sectors, tailoring its solutions to meet the specific demands of these industries.

Product Offerings

Beyond robotics, GreyOrange offers comprehensive automation solutions, including warehouse management software and automated storage and retrieval systems. Locus Robotics specializes in collaborative robots for order fulfillment, providing a streamlined solution focused solely on robotic assistance.

Market Overview and Trends

The robotic warehouse market is experiencing significant growth, projected to expand at a compound annual growth rate (CAGR) of 26% from 2020 to 2025, according to Mordor Intelligence. Factors driving this growth include the rising demand for automation in warehousing to improve productivity and efficiency while reducing labor costs. Major players in this market include GreyOrange, Locus Robotics, Amazon's formerly acquired Kiva Systems, Fetch Robotics, and Geek+.

Space Optimization and Cost Efficiency

Robotic technology in warehouses optimizes space utilization by navigating narrow aisles and accessing high shelves, enabling more products to be stored within the same footprint. This is especially beneficial in urban areas with high real estate costs. Additionally, robots can operate continuously, increasing order fulfillment speed and reducing the need for extended human shifts.

Benefits of GreyOrange and Locus Robotics

Advantages of GreyOrange

- Fully Autonomous: Minimal human intervention required.

- Scalable Solutions: Capable of handling multiple items simultaneously.

- Customizable: Adapts to various industries including retail, e-commerce, and healthcare.

- Real-Time Analytics: Provides data-driven insights for optimized operations.

- User-Friendly Interface: Easy monitoring and control for warehouse managers.

Advantages of Locus Robotics

- Collaborative Design: Works alongside human workers, enhancing flexibility.

- Seamless Integration: Easily integrates with existing warehouse management systems.

- Advanced Navigation: Utilizes sensors and cameras for efficient movement and obstacle avoidance.

- Route Optimization: Reduces travel time and increases productivity.

Pricing Models Comparison

GreyOrange's Subscription-Based Model

GreyOrange's Butler system operates on a subscription-based pricing model, where companies pay a monthly or annual fee based on warehouse size and the number of robots deployed. This model provides predictable costs and scalability according to business needs.

Locus Robotics' Pay-Per-Robot-Hour Model

Locus Robotics employs a pay-per-robot-hour pricing approach, allowing companies to pay based on the number of robots and the hours utilized. This flexible model enables businesses to scale their robotic workforce up or down as required, optimizing cost-efficiency.

Case Studies: Success Stories with GreyOrange and Locus Robotics

GreyOrange

- Walmart: Implemented the Butler system in one of its warehouses, resulting in a 50% increase in productivity.

- Decathlon: Enhanced warehouse operations through automation.

- Nitori: Streamlined inventory management and order fulfillment.

Locus Robotics

- GEODIS: Deployed Locus Robotics in a warehouse, achieving a 60% increase in productivity.

- DHL: Improved order fulfillment efficiency using collaborative robots.

- Boots UK: Enhanced warehouse operations through robotic assistance.

Future Developments in Robotic Warehousing

The robotic warehouse industry is poised for continued growth, with advancements in artificial intelligence and machine learning enhancing robot capabilities. Future developments include:

- Enhanced AI Integration: Smarter robots capable of more complex decision-making.

- Human-Robot Collaboration: Increased synergy between human workers and robots.

- Scalability: More versatile systems that can adapt to varying warehouse sizes and types.

- Energy Efficiency: Development of more energy-efficient robotic systems.

Choosing the Right Solution for Your Business

Selecting between GreyOrange and Locus Robotics depends on several factors, including your warehouse requirements, budget, and operational goals.

- GreyOrange: Ideal for businesses seeking a fully autonomous system to optimize inventory management and order picking.

- Locus Robotics: Suitable for businesses looking for a flexible solution that complements human workers and adapts to changing needs.

Conclusion: GreyOrange vs. Locus Robotics

Both GreyOrange and Locus Robotics are at the forefront of the robotic warehouse market, offering innovative solutions to automate warehouse operations. GreyOrange provides a fully autonomous system capable of optimizing inventory and order processes, while Locus Robotics offers collaborative robots that work alongside human workers for greater flexibility. Their distinct pricing models—subscription-based for GreyOrange and pay-per-robot-hour for Locus Robotics—cater to different business needs and budgets. Ultimately, the choice between the two depends on your specific business requirements, operational goals, and budgetary considerations.