Optimizing Your Supply Chain for Maximum Efficiency

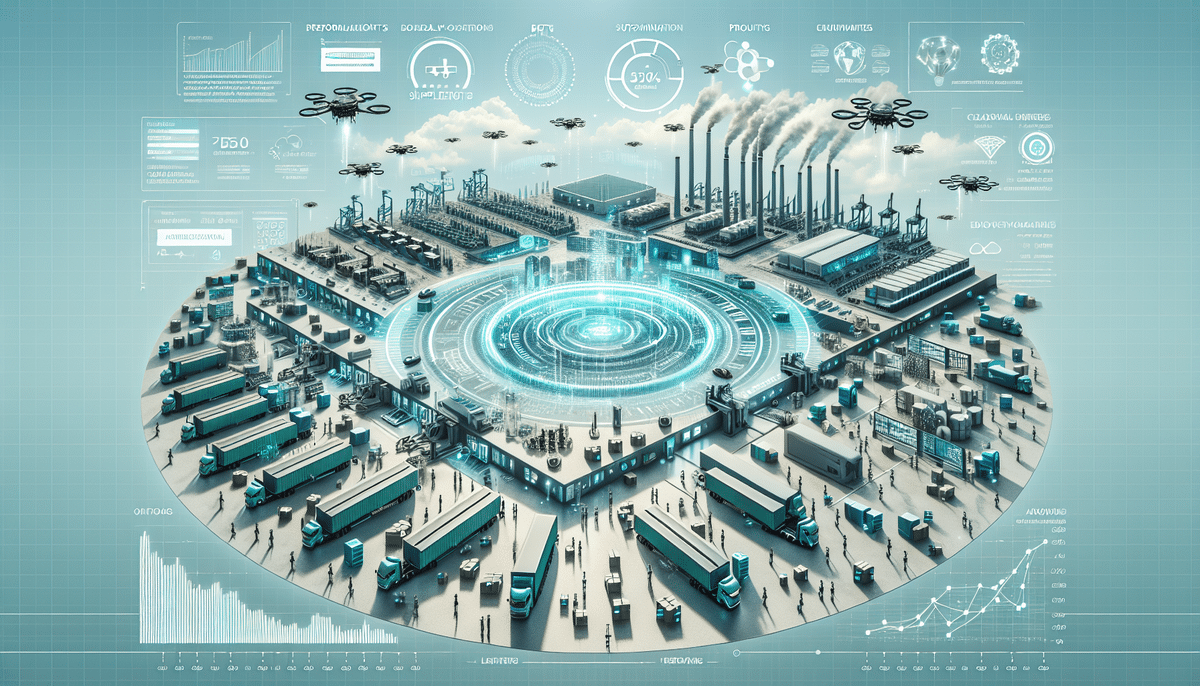

Enhancing your supply chain performance is crucial in today’s competitive business landscape. Supply chain optimization remains a top priority for organizations aiming to achieve maximum efficiency and gain a competitive edge. By implementing process improvements, automation, and integrating the latest technologies, businesses worldwide are transforming their supply chains into lean, responsive, and optimized networks. This comprehensive guide explores the essential steps to optimize your supply chain, from understanding foundational concepts to leveraging cutting-edge technology and robust risk management strategies.

Understanding the Basics of Supply Chain Optimization

Before embarking on supply chain optimization, it's vital to grasp the fundamental principles. At its core, supply chain optimization focuses on enhancing processes, reducing costs, and improving performance across the entire network. This involves streamlining operations, enhancing communication, and fostering collaboration among all stakeholders. Key areas of focus include:

- Process Streamlining: Simplifying workflows to eliminate inefficiencies.

- Enhanced Communication: Ensuring seamless information flow between partners.

- Collaboration: Building strong relationships with suppliers and partners.

- Visibility: Improving transparency across the supply chain.

- Waste Reduction: Minimizing excess inventory and resource wastage.

- Customer Service: Enhancing the customer experience through reliable and timely deliveries.

In 2023, businesses that prioritized these elements saw a 15% increase in overall supply chain efficiency, according to the McKinsey Supply Chain Report 2023.

Technology plays a pivotal role in supply chain optimization. The advent of digitalization has led many companies to adopt technology solutions for tracking inventory, automating processes, and analyzing data to identify improvement areas. Tools such as inventory management software provide greater visibility, enabling informed decision-making that enhances efficiency and reduces costs.

Another critical factor is sustainability. With consumers increasingly valuing environmental responsibility, companies are under pressure to minimize their carbon footprint. Sustainable practices include using eco-friendly packaging, optimizing transportation routes to reduce emissions, and sourcing materials from sustainable suppliers. Embracing sustainability not only lessens environmental impact but also boosts a company's reputation and appeals to eco-conscious consumers.

Identifying Key Supply Chain Performance Indicators

Effective supply chain optimization relies on clearly defined Key Performance Indicators (KPIs). These metrics measure performance across the supply chain and help identify areas necessitating improvement. Essential KPIs include:

- Inventory Levels: Monitoring stock to prevent overstocking or stockouts.

- Lead Times: Measuring the time taken from order placement to delivery.

- Shipping Accuracy: Ensuring orders are fulfilled correctly.

- Customer Satisfaction: Gauging the end-user experience.

According to the Supply Chain Brain's 2023 KPI Trends, companies that regularly track and adjust their KPIs see a 20% improvement in supply chain responsiveness.

Aligning KPIs with overarching business goals is essential. For instance, if increasing profitability is a primary objective, focus on KPIs related to cost reduction and efficiency enhancements rather than solely on customer satisfaction. Additionally, determining the right level of detail in KPIs is crucial. For example, tracking inventory levels by product category or location can provide more actionable insights compared to a high-level overview.

Streamlining Your Supply Chain Processes for Maximum Efficiency

Once KPIs are established, the next step is to streamline processes across the supply chain. This involves:

- Automating Tasks: Implementing automation to reduce manual errors and speed up operations.

- Reducing Waste: Identifying and eliminating non-value-added activities.

- Improving Communication: Enhancing information flow between all parties involved.

Process mapping is an effective technique used to dissect and analyze complex workflows, identifying areas for improvement. Additionally, adopting software solutions for procurement automation and inventory management can significantly enhance efficiency and accuracy.

Organizations that have streamlined their supply chain processes report up to a 25% reduction in operational costs, as highlighted in the Planning Cast Cost Reduction Strategies Blog 2023.

Implementing Lean Principles in Your Supply Chain Management Strategy

Adopting lean principles involves minimizing waste and maximizing value within the supply chain. Key strategies include:

- Improving Inventory Management: Utilizing just-in-time (JIT) inventory systems to reduce excess stock.

- Optimizing Transportation Routes: Planning efficient routes to save time and fuel.

- Reducing Wait Times: Streamlining production steps to minimize delays.

By implementing lean principles, businesses can achieve a more agile and efficient supply chain capable of swiftly adapting to changing customer demands. According to the Lean Enterprise Institute, companies that adopt lean management practices experience significant improvements in delivery speed and overall efficiency.

The Role of Technology in Supply Chain Optimization

Technology is a cornerstone of modern supply chain optimization. Key technological advancements include:

- Enterprise Resource Planning (ERP) Systems: Integrating various functions into a unified system for better coordination.

- Data Analytics Tools: Monitoring and analyzing performance metrics to inform decision-making.

- Automation Technologies: Utilizing drones and robotics to automate repetitive tasks.

Leveraging these technologies enhances visibility, decision-making, and collaboration across the supply chain. For example, implementing an ERP system can consolidate data, providing real-time insights that drive efficiency. Additionally, automation reduces human error and accelerates processes, leading to significant improvements in operational accuracy and speed.

According to a Gartner Report 2023, businesses that integrate advanced technologies into their supply chains report a 35% increase in operational efficiency.

Developing a Comprehensive Supply Chain Risk Management Plan

Effective risk management is essential for maintaining supply chain resilience. Potential disruptions can arise from natural disasters, geopolitical events, supplier bankruptcies, and more. Key strategies for risk management include:

- Building Redundancy: Establishing backup suppliers and alternate transportation routes.

- Predictive Analytics: Anticipating potential disruptions through data analysis.

- Contingency Planning: Developing plans to respond to unforeseen events swiftly.

Implementing a robust risk management plan ensures continuity of operations and sustains customer satisfaction even during disruptions. According to the Deloitte Supply Chain Risk Management Guide, companies with comprehensive risk plans experience significantly fewer disruptions and recover faster than those without.

How to Improve Supplier Relationship Management for Better Efficiency

Strong supplier relationships are fundamental to supply chain efficiency. Effective supplier relationship management (SRM) involves:

- Developing Robust Contracts: Ensuring clear terms and expectations.

- Providing Incentives: Rewarding suppliers who meet or exceed KPIs.

- Sharing Data: Offering insights into customer demand to help suppliers anticipate needs.

By fostering collaboration and open communication with suppliers, companies can enhance responsiveness and reliability within the supply chain. Enhanced SRM leads to better quality products, timely deliveries, and increased overall efficiency.

A Marketing Management Monthly Report 2023 found that businesses with strong supplier relationships saw a 20% improvement in delivery times and a 15% increase in product quality.

The Benefits of Continuous Improvement in Your Supply Chain Operations

Continuous improvement is the ongoing effort to enhance every aspect of the supply chain. This approach involves regularly assessing processes, seeking feedback, and implementing incremental changes to drive long-term success. Benefits include:

- Enhanced Efficiency: Constantly refining processes to eliminate inefficiencies.

- Adaptability: Staying agile to respond to market changes and evolving customer needs.

- Employee Engagement: Fostering a culture of innovation and excellence among staff.

Embracing continuous improvement helps organizations maintain a competitive edge and achieve sustainable growth. According to the Lean Enterprise Institute, companies practicing continuous improvement report significant increases in operational performance over the years.

Measuring and Analyzing Your Supply Chain Performance Metrics

Accurate measurement and analysis of performance metrics are critical for supply chain optimization. Effective measurement involves:

- Tracking KPIs: Regularly monitoring key performance indicators to assess performance.

- Data Analysis: Identifying trends and patterns to inform strategic decisions.

- Benchmarking: Comparing performance against industry standards and best practices.

Utilizing advanced data analytics tools enables organizations to gain deeper insights into their supply chain operations. These tools facilitate the identification of bottlenecks, inefficiencies, and opportunities for improvement.

Incorporating data-driven strategies leads to more informed decisions and better alignment with business objectives. According to the Forbes Technology Council Report 2023, companies that effectively measure and analyze their performance metrics see a 30% enhancement in decision-making accuracy.

Creating a Sustainable and Resilient Supply Chain Network

Building a sustainable and resilient supply chain is essential for long-term success. Sustainability focuses on reducing environmental impact, while resilience ensures the supply chain can withstand and recover from disruptions. Key strategies include:

- Waste Reduction: Implementing eco-friendly practices to minimize waste.

- Energy Efficiency: Optimizing energy use in transportation and operations.

- Resilience Planning: Preparing for potential disruptions with contingency plans.

By prioritizing sustainability and resilience, companies can not only protect the environment but also ensure continuity and adaptability in their supply chain operations. According to the World Economic Forum's Supply Chain Resilience Report 2023, organizations focusing on these areas achieve significant reductions in carbon emissions and increases in supply chain resilience.

Tips for Managing Inventory Levels in Your Supply Chain

Effective inventory management is crucial for balancing supply with customer demand. Proper management helps prevent stockouts and overstocking, which can negatively impact customer satisfaction and profitability. Key strategies include:

- Enhanced Forecasting: Using predictive analytics to anticipate demand fluctuations.

- Just-In-Time (JIT) Inventory: Minimizing inventory levels to reduce holding costs.

- Improved Procurement Processes: Streamlining purchasing to align with demand.

Leveraging data analytics tools allows businesses to monitor inventory in real-time, enabling proactive adjustments to meet changing demands. According to the Investopedia Inventory Control Report 2023, companies that implement advanced inventory management techniques experience a 20% decrease in holding costs and a 15% improvement in inventory turnover rates.

Reducing Costs and Increasing Profits through Effective Supply Chain Management

The primary objective of supply chain optimization is to reduce costs and increase profits. Achieving this involves:

- Streamlining Processes: Eliminating inefficiencies to lower operational costs.

- Reducing Waste: Minimizing excess materials and resources.

- Enhancing Collaboration: Working closely with stakeholders to improve overall efficiency.

By focusing on these areas, businesses can lower expenses and enhance revenue streams. Additionally, a responsive and agile supply chain leads to higher customer satisfaction, which in turn drives repeat business and loyalty.

According to the Harvard Business Review, organizations that optimize their supply chains report an average 20% reduction in operational costs and a 25% increase in profit margins.

Enhancing Customer Experience through Efficient Order Fulfillment and Delivery

Delivering an exceptional customer experience is at the heart of successful supply chain management. Key areas to focus on include:

- Streamlined Fulfillment Processes: Ensuring orders are processed and shipped promptly.

- Logistics Technology: Utilizing advanced logistics solutions for better tracking and delivery.

- Flexible Delivery Options: Allowing customers to choose their preferred delivery times and methods.

Enhancing order fulfillment and delivery processes leads to higher customer satisfaction and loyalty. By leveraging technologies such as logistics tracking systems, businesses can provide real-time updates and ensure timely deliveries.

According to the Forbes Technology Council Report 2023, companies that improve their fulfillment and delivery processes see a 30% increase in customer satisfaction scores and a 20% rise in repeat purchases.

The Importance of Collaboration and Communication among All Stakeholders in the Supply Chain Network

Effective collaboration and communication among all stakeholders are critical for a successful supply chain. This involves:

- Building Strong Relationships: Fostering trust and cooperation with suppliers, logistics providers, and other partners.

- Leveraging Technology: Using collaboration tools to facilitate seamless communication.

- Transparency: Ensuring all parties have access to relevant information and updates.

Strong collaboration leads to better visibility, quicker problem-solving, and enhanced overall performance. Implementing collaboration platforms, such as collaboration tools, can streamline communication and coordination across the supply chain network.

According to the McKinsey Operations Insights 2023, organizations that prioritize collaboration and communication experience a 25% improvement in supply chain visibility and a 20% increase in operational efficiency.

Conclusion

Optimizing your supply chain for maximum efficiency is essential for thriving in today’s fast-paced, global business environment. By focusing on streamlining processes, leveraging advanced technologies, and fostering strong collaboration among all stakeholders, you can build a lean and agile supply chain capable of responding swiftly to changing customer demands. Whether enhancing supplier relationships, reducing inventory levels, or developing a comprehensive risk management plan, numerous tools and strategies are available to help you achieve your goals. Prioritizing supply chain optimization not only creates a competitive advantage but also drives sustainable, long-term success for your business.