Maximizing Warehouse Efficiency with Floor Stacked Containers

Introduction

In the world of warehousing, maximizing space is essential for improving efficiency and profitability. One effective strategy is the use of floor stacked containers. These containers are versatile and can hold a wide range of products, making them a popular choice for many warehouses. This article explores the various benefits of floor stacked containers, their types, and provides tips for proper implementation. We will also discuss their impact on warehouse efficiency, environmental benefits, and future technologies.

The Benefits of Floor Stacked Containers in Warehouses

Floor stacked containers offer several advantages that make them a staple in the warehousing industry:

- Space Utilization: These containers can be easily stacked on top of each other, allowing for more products to be stored in a single area, thereby optimizing space.

- Versatility: Suitable for a wide variety of products, from small items to heavy machinery, they can be easily transported within the warehouse.

- Durability: Designed to withstand the rigors of a warehouse environment, floor stacked containers are a long-lasting investment.

- Cost Savings: Reduced space requirements can lead to savings on rent or lease costs for larger warehouse spaces. Additionally, their reusable nature minimizes the need for frequent replacements.

According to a McKinsey report, efficient space utilization can increase warehouse productivity by up to 30%.

How Floor Stacked Containers Can Save You Money and Time

Implementing floor stacked containers can result in substantial savings in both time and money:

- Real Estate Costs: By maximizing space utilization, businesses can save on real estate expenses by reducing the need for additional storage areas.

- Operational Efficiency: Streamlined handling and transportation of products reduce the time spent on these activities, enhancing overall productivity.

- Shipping Costs: Secure stacking allows for larger quantities to be transported at once, lowering shipping expenses.

Moreover, improved safety measures associated with sturdy and durable containers reduce the risk of workplace accidents, leading to fewer downtime and associated costs.

The Different Types of Floor Stacked Containers

Choosing the right type of floor stacked container is crucial for meeting specific storage needs:

Plastic Containers

Lightweight and easy to clean, plastic containers are ideal for storing items that require sanitation, such as food products.

Metal Containers

Best suited for heavy loads, metal containers offer superior durability and are ideal for storing machinery and equipment.

Wire Baskets

These provide excellent ventilation and visibility, making them suitable for items that need to remain dry or require easy access.

Wooden Containers

Sturdy and capable of withstanding various environmental conditions, wooden containers are excellent for long-term storage.

Cardboard Boxes

A cost-effective option for short-term storage and transportation, cardboard boxes are lightweight and easy to assemble, though less durable than other types.

Collapsible Containers

These containers save space when not in use and are available in materials like plastic and metal, offering flexibility for dynamic storage needs.

When selecting containers, consider the storage environment. For instance, containers used in cold rooms should withstand low temperatures, while those in humid areas should resist water damage and mold growth.

Tips for Successfully Implementing Floor Stacked Containers in Your Warehouse

To ensure a smooth implementation of floor stacked containers, follow these best practices:

- Planning: Designate specific areas for storing and organizing containers. Create a layout that facilitates easy access and movement.

- Labeling: Clearly label containers to simplify location tracking and inventory management.

- Stacking Support: Use pallets or other supports to secure containers properly. Adhere to weight limits to prevent overloading.

- Training: Train your team on proper handling and storage procedures to minimize accidents and improve efficiency.

- Environmental Considerations: Accommodate specific storage conditions required by different products, such as temperature control or light protection.

- Maintenance: Regularly inspect containers for damage and perform necessary maintenance to extend their lifespan.

How to Safely Stack Heavy Items with Floor Stacked Containers

Safety is paramount when stacking heavy items. Follow these guidelines to mitigate risks:

- Weight Limits: Never exceed the recommended weight limits of containers. Overloading can lead to accidents and product damage.

- Stable Base: Use supports or dividers to create a stable base, preventing items from shifting during storage or transport.

- Proper Equipment: Utilize forklifts and pallet jacks to handle heavy containers safely.

- Regular Inspections: Continuously monitor stacked containers for signs of instability or damage.

Best Practices for Organizing and Labeling Floor Stacked Containers

Effective organization and labeling enhance warehouse efficiency:

- Accessibility: Store frequently used items at the top for easy access.

- Categorization: Group similar items together and assign specific labels to each container.

- Weight Distribution: Place heavier items at the bottom of the stack to maintain stability.

Implementing these practices ensures that your team can locate and retrieve items swiftly, reducing time spent on inventory management.

The Impact of Floor Stacked Containers on Warehouse Efficiency

Floor stacked containers significantly enhance warehouse efficiency by:

- Optimizing Space: Increased storage capacity means more products can be housed without expanding the physical footprint.

- Reducing Transport Times: Efficient stacking minimizes the distance products need to be moved within the warehouse.

- Streamlining Workflow: Organized storage reduces clutter, facilitating a smoother workflow and boosting productivity.

According to the Forbes Technology Council, businesses that implement effective stacking methods can see operational cost reductions of up to 20%.

Innovative Ways to Use Floor Stacked Containers for Better Space Utilization

Innovative stacking techniques can further optimize space utilization:

- Vertical Storage Systems: Creating pyramid-like stacks can increase storage capacity while minimizing floor space usage.

- Rotating Shelves: Implementing rotating shelves allows for efficient storage of small items, making them easily accessible.

- Modular Systems: Combining different types of containers in a modular setup can cater to varying storage needs.

By adopting these innovative methods, warehouses can explore new possibilities for maximizing space and enhancing productivity.

The Environmental Benefits of Using Floor Stacked Containers in Warehouses

Floor stacked containers contribute to environmental sustainability in several ways:

- Reusability: These containers can be reused multiple times, reducing waste and the demand for new packaging materials.

- Resource Efficiency: Maximizing space utilization decreases the need for additional storage facilities, lowering resource consumption.

- Reduced Emissions: Efficient stacking and transportation minimize transportation-related emissions.

Embracing sustainable storage solutions like floor stacked containers helps businesses reduce their environmental footprint and promote a greener future.

Common Mistakes to Avoid When Using Floor Stacked Containers

While floor stacked containers are beneficial, certain mistakes can undermine their effectiveness:

- Overloading Containers: Exceeding weight limits can cause accidents and damage to both containers and products.

- Poor Stacking Practices: Incorrect stacking can lead to instability, increasing the risk of collapse and injury.

- Inadequate Labeling: Failure to label containers properly can lead to confusion and inefficiencies in inventory management.

- Neglecting Maintenance: Ignoring regular inspections can result in unnoticed wear and tear, compromising container integrity.

Avoiding these common mistakes ensures that your warehouse operations remain safe, efficient, and cost-effective.

How to Choose the Right Size and Material for Your Floor Stacked Containers

Selecting the appropriate size and material for floor stacked containers is crucial for optimal performance:

- Product Size and Weight: Assess the dimensions and weight of the products to determine suitable container size and weight capacity.

- Material Durability: Choose materials that can withstand the specific demands of your warehouse environment, such as temperature fluctuations or moisture.

- Sanitization: Ensure containers are easy to clean and sanitize, especially if storing perishable or sensitive items.

- Reusability: Opt for materials that allow for long-term reuse to maximize cost efficiency.

By carefully selecting the right size and material, you can ensure that your containers are both effective and durable, providing lasting value to your operations.

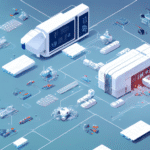

The Future of Warehousing with Floor Stacked Container Technology

The integration of advanced technologies with floor stacked containers is shaping the future of warehousing:

- Automation and Robotics: Automated storage and retrieval systems (AS/RS) utilize floor stacked containers that can be moved and organized by robots, enhancing efficiency and reducing labor costs.

- Digital Tracking: Implementing sensors and digital tagging provides real-time updates on container locations and movements, improving inventory management and operational oversight.

- Smart Containers: Future containers may feature built-in technology for monitoring environmental conditions, ensuring optimal storage conditions for sensitive products.

Embracing these technological advancements will further enhance the benefits of floor stacked containers, leading to more intelligent and responsive warehouse operations.

Successful Case Studies of Companies Using Floor Stacked Containers

Several companies have reaped significant benefits from implementing floor stacked containers:

Smart Modular Technologies

This electronics manufacturer implemented floor stacked containers, resulting in a 17% reduction in floor space and a 75% reduction in pallets used. These improvements led to streamlined operations and cost savings.

Jabil

Jabil, a leading manufacturing company, utilized floor stacked containers in their warehouses, achieving a 22% reduction in footprint and a 100% increase in inventory accuracy. This implementation enhanced their operational efficiency and inventory management.

These case studies demonstrate the tangible benefits of adopting floor stacked containers, providing valuable insights for other businesses considering similar strategies.

Conclusion

Floor stacked containers are a versatile and effective solution for maximizing space utilization in warehouses. They offer numerous benefits, including cost and time savings, increased efficiency, and sustainability. By following best practices, avoiding common mistakes, and selecting the right size and material, businesses can successfully implement floor stacked containers in their warehouse operations. The future of warehousing is promising, with advancements in automation and digital tracking set to further enhance the effectiveness of floor stacked container technology. Learning from successful case studies can provide actionable strategies to harness the full potential of this efficient storage solution.