Cycle Counting: A Comprehensive Guide to E-Commerce Logistics

In the rapidly evolving world of e-commerce logistics, inventory management stands as one of the paramount challenges businesses encounter. Accurately tracking product levels and locations can be intricate, with errors potentially leading to lost sales, dissatisfied customers, and significant financial setbacks. One of the most effective strategies to maintain inventory accuracy is through cycle counting. This guide delves into the fundamentals of cycle counting, its significance in e-commerce logistics, and the steps to establish a successful cycle counting system tailored for your business.

We will also explore the tools and technologies that enhance accuracy, address common implementation challenges, outline best practices for conducting cycle counts, and highlight the pivotal role of data analytics in refining this process. Additionally, we'll discuss how to assess the effectiveness of your cycle counting system, integrate it with other inventory management processes, and showcase success stories of businesses that have effectively implemented cycle counting.

Understanding the Basics of Cycle Counting

Cycle counting is an inventory auditing procedure that involves counting a subset of inventory in a specific location on a specific day. Instead of performing a full physical inventory count, cycle counting spreads the effort throughout the year, ensuring continuous inventory accuracy. According to a study by Supply Chain Digital, businesses that implement cycle counting see a 99% inventory accuracy rate compared to 97% in those that do not.

Unlike traditional inventory counting methods that require shutting down operations to count all inventory at once, cycle counting allows businesses to maintain regular operations without significant downtime. By routinely monitoring inventory levels, discrepancies can be identified and rectified promptly, preventing issues such as stockouts and overstocking that can adversely affect a company's financial health.

Successful cycle counting necessitates meticulous planning and execution. Key considerations include determining which items to count, the frequency of counts, and assigning responsibility to specific team members. Establishing a comprehensive cycle counting plan ensures that the inventory management strategy delivers its full potential benefits.

The Importance of E-Commerce Logistics in Cycle Counting

Effective e-commerce logistics are fundamental to the success of cycle counting. A robust logistics system enables accurate tracking of inventory across the supply chain, minimizing errors during the counting process. According to a report by Supply Chain Brain, businesses with advanced logistics systems experience up to a 30% improvement in inventory accuracy.

A well-managed logistics system optimizes inventory management by analyzing sales data and tracking inventory levels in real-time. This capability allows businesses to make informed decisions about restocking, thereby preventing the pitfalls of stockouts and overstocking that can skew cycle counts.

Moreover, efficient logistics play a crucial role in handling returns and exchanges. A streamlined returns process ensures that returned items are accurately re-entered into inventory, maintaining data integrity and customer satisfaction.

How to Set Up a Successful Cycle Counting System for Your E-Commerce Business

Establishing a cycle counting system requires a strategic approach:

- Analyze Current Inventory: Assess your existing inventory levels and identify discrepancies.

- Determine Counting Frequency: Decide how often each item category should be counted based on turnover rates.

- Assign Responsibilities: Designate team members responsible for conducting counts.

- Set Accuracy and Efficiency Targets: Establish clear metrics to measure the success of the cycle counting process.

Once the system is in place, it's essential to regularly review and refine it. This includes updating technology, adjusting staffing levels, modifying counting frequency, and revising accuracy targets to ensure the system remains effective over time.

Training is another critical component. Providing comprehensive training on how to conduct cycle counts, utilize relevant tools, and resolve discrepancies ensures that your team can execute the process accurately and efficiently, leading to improved inventory management and business outcomes.

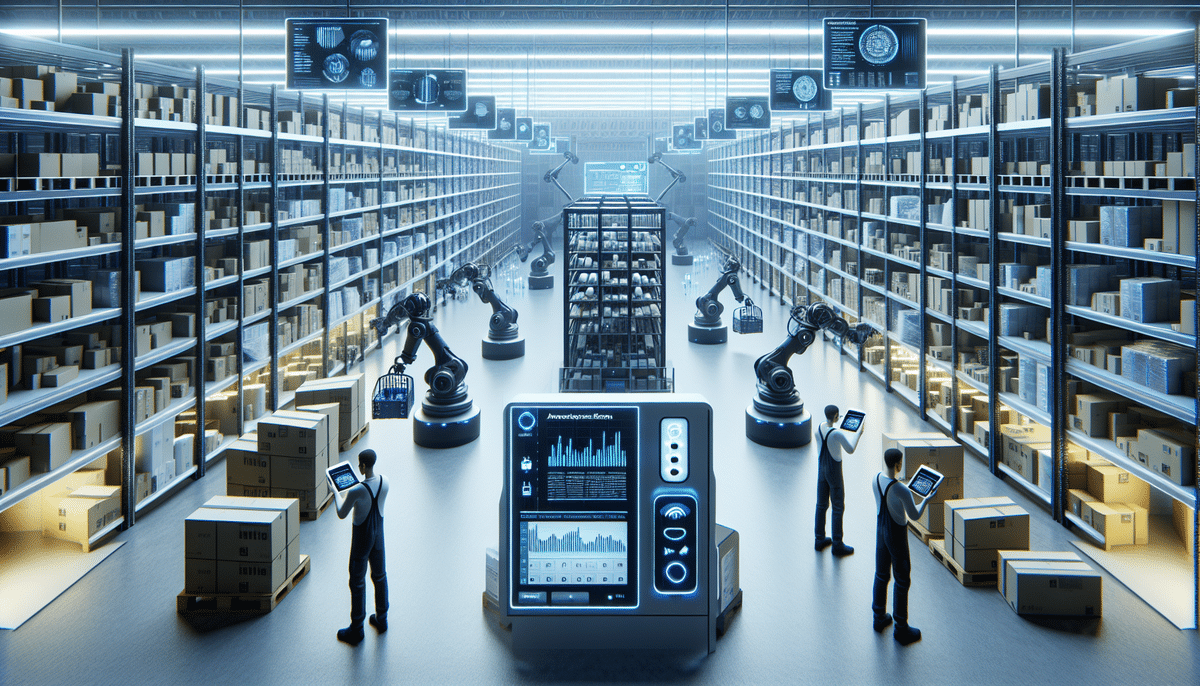

Tools and Technologies for Accurate Cycle Counting in E-Commerce Logistics

Leveraging the right tools and technologies is pivotal in enhancing the accuracy of cycle counting:

- Mobile Scanning Devices: Handheld devices that scan barcodes or RFID tags, facilitating quick and accurate data capture.

- RFID (Radio-Frequency Identification) Tags: Enable automatic identification and tracking of inventory items, reducing manual errors.

- Barcode Scanners: Essential for quickly identifying and recording inventory items during counts.

Incorporating these technologies can automate the counting process, minimize human error, and provide real-time data, thereby significantly improving cycle counting accuracy.

For more information on advanced inventory management technologies, visit ShipScience Inventory Management Solutions.

Common Challenges in Implementing a Cycle Counting System and How to Overcome Them

Implementing a cycle counting system can present several challenges:

- Employee Resistance: Staff may be hesitant to adopt new processes. Overcome this by providing comprehensive training and demonstrating the benefits of cycle counting.

- Insufficient Resources: Limited manpower or outdated technology can hinder implementation. Investing in the right tools and allocating sufficient resources is crucial.

- Unexpected Errors: Discrepancies and errors can arise unexpectedly. Establishing protocols for error resolution and continuous improvement can mitigate this issue.

Collaborating with logistics and e-commerce experts can provide tailored solutions to address specific challenges, ensuring a smoother implementation process.

Additionally, investing in reliable inventory management software is essential. Tools such as ShipScience Inventory Software offer features that streamline the cycle counting process and enhance data accuracy.

Best Practices for Conducting a Cycle Count in E-Commerce Logistics

Adopting best practices can significantly enhance the effectiveness of cycle counting:

- Create a Detailed Schedule: Establish a consistent schedule for cycle counts to ensure they are performed regularly.

- Utilize Advanced Technology: Implement mobile scanning devices or barcode readers to increase speed and accuracy.

- Maintain Comprehensive Records: Document both expected and actual counts to track discrepancies and identify patterns.

- Investigate Discrepancies: Promptly review and resolve any variances to maintain inventory accuracy.

Engaging your team in the cycle counting process is also beneficial. Encouraging team members to report issues or discrepancies can help identify potential problems early, ensuring a more accurate and efficient cycle count.

Providing ongoing training on effective cycle counting techniques and the use of relevant equipment further ensures the process is carried out correctly.

The Role of Data Analytics in Improving Cycle Counting Accuracy

Data analytics plays a critical role in enhancing the accuracy of cycle counting. By analyzing data collected from each cycle count, businesses can identify trends, pinpoint accuracy issues, and make data-driven improvements to their inventory management systems.

One significant advantage of data analytics is its ability to detect and prevent inventory shrinkage. Regular data analysis allows businesses to identify discrepancies between inventory records and actual stock levels, enabling early detection of issues such as theft or loss.

Moreover, data analytics helps optimize inventory levels by forecasting demand accurately, ensuring that businesses maintain optimal stock levels without overstocking. This leads to better resource allocation and improved customer satisfaction.

For insights into leveraging data analytics for inventory management, refer to the latest reports from Gartner and Investopedia.

Benefits of Regular Cycle Counts for Your E-Commerce Business

Implementing regular cycle counts offers numerous benefits for e-commerce businesses:

- Improved Inventory Accuracy: Regular counts ensure that inventory records accurately reflect actual stock levels.

- Reduced Risk of Stockouts: Early detection of discrepancies helps prevent stockouts, ensuring products are available when customers need them.

- Enhanced Customer Satisfaction: Accurate inventory management leads to better order fulfillment, resulting in happier customers.

- Cost Savings: Preventing overstocking and stockouts reduces holding costs and lost sales.

According to a Logistics Management report, businesses that perform regular cycle counts can reduce inventory holding costs by up to 20% while increasing inventory turnover rates.

How to Evaluate the Effectiveness of Your Cycle Counting System

Evaluating the effectiveness of your cycle counting system is essential for continuous improvement. Key metrics to monitor include:

- Inventory Accuracy: The degree to which inventory records match actual stock levels.

- Labor Costs: The cost associated with conducting cycle counts.

- Cycle Count Costs: Expenses related to the equipment and technology used in the counting process.

Regularly reviewing these metrics allows businesses to identify areas for improvement and adjust their cycle counting strategies accordingly. Utilizing dashboards and reporting tools can facilitate real-time monitoring and analysis.

For guidance on evaluating inventory systems, visit ShipScience Evaluation Tools.

Integrating Your Cycle Counting with Other Inventory Management Processes

Seamless integration of cycle counting with other inventory management processes is crucial for comprehensive operations. This integration can involve:

- Inventory Management Software: Integrate cycle counting with order fulfillment and shipping systems to ensure real-time data synchronization.

- Automated Reordering: Use data from cycle counts to automate reorder points, preventing stockouts and overstocking.

- Synchronized Data Systems: Ensure all inventory-related data is centralized, reducing the risk of discrepancies across different platforms.

By creating an interconnected system, businesses can achieve greater inventory visibility, streamline operations, and make informed decisions based on accurate data.

Learn more about integrating inventory systems at ShipScience Integration Solutions.

Case Studies: Successful Implementation of Cycle Counting in E-Commerce Logistics

Numerous e-commerce businesses have successfully implemented cycle counting, resulting in significant improvements in inventory accuracy and operational efficiency:

- Food Delivery Service: By utilizing RFID scanning technology and mobile devices, the company reduced stock inaccuracies by 98.7% and enhanced warehouse efficiency by 13%.

- Tech Company: Implementing barcoding and cloud computing technology led to a nearly 60% reduction in inventory shrinkage and a dramatic increase in inventory accuracy and efficiency.

These success stories underscore the value of adopting cycle counting in e-commerce logistics, highlighting how the right tools and strategies can drive substantial business improvements.

For more detailed case studies, visit our Case Studies Section.

Implementing cycle counting in your e-commerce logistics operations is essential for maintaining accurate inventory levels, reducing stockouts and lost sales, and ultimately enhancing customer satisfaction. By understanding the fundamentals of cycle counting, leveraging the appropriate tools and technologies, and adhering to best practices, you can establish a successful cycle counting system that propels your business to new heights.