Introduction to 3PL Logistics Fulfillment and Portal Warehousing

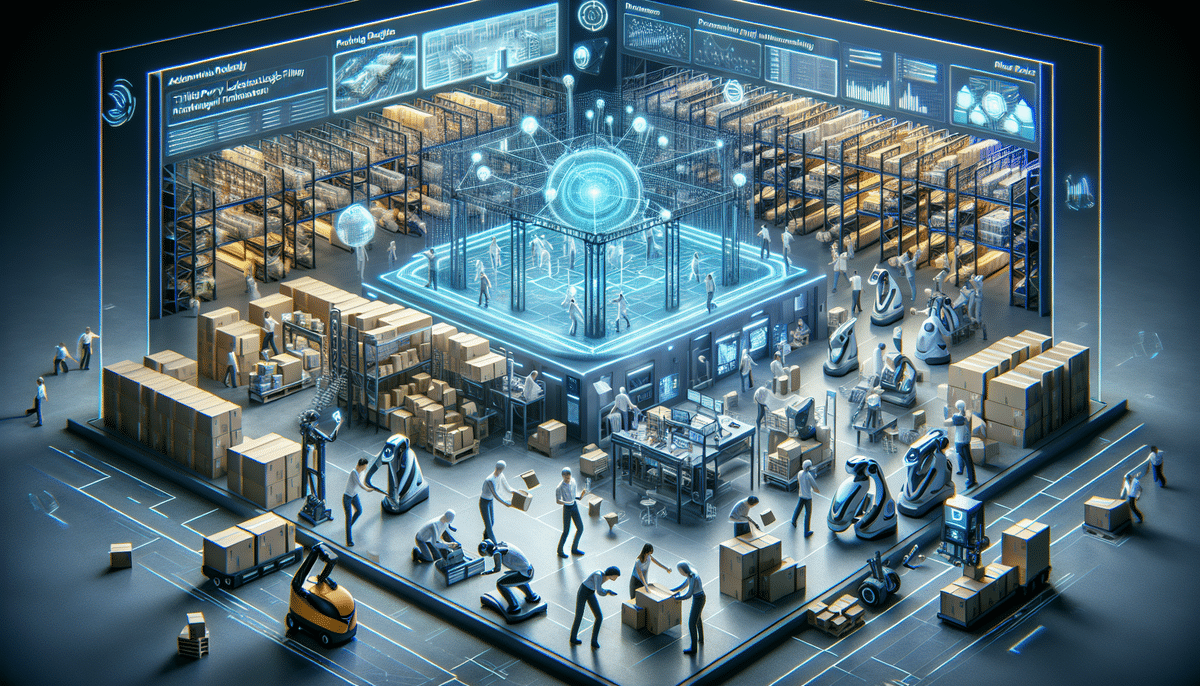

In today's fast-paced business environment, outsourcing logistics functions to third-party logistics (3PL) providers has become increasingly popular. 3PL logistics fulfillment involves delegating logistics tasks to organizations specialized in fulfilling customer orders, managing inventory, and providing warehouse and transportation management services. Concurrently, businesses are exploring innovative warehousing approaches like portal warehousing. This article offers a comprehensive overview of 3PL logistics fulfillment, explains how it works, and delves into the concept of portal warehousing and its benefits for businesses.

Understanding 3PL Logistics Fulfillment

3PL logistics fulfillment involves outsourcing logistics functions to a specialized 3PL provider that manages transportation, distribution, and warehousing services. Acting as a single point of contact for all logistics-related activities, 3PL providers handle picking and packing, inventory management, and transportation while supplying the necessary technology to effectively manage the supply chain.

One of the primary benefits of using a 3PL logistics provider is the ability to scale operations quickly and efficiently. As businesses grow, managing logistics in-house can become challenging. Outsourcing to a 3PL provider alleviates this burden and often leads to cost savings and improved supply chain efficiency due to established relationships with carriers and warehouses. According to a Statista report (2023), the global 3PL market is expected to reach $1.3 trillion by 2027, underscoring its growing importance in the logistics sector.

The Concept and Benefits of Portal Warehousing

Portal warehousing represents an innovative approach in the warehousing industry, offering businesses access to a network of shared warehouses managed by third-party logistics providers through a digital platform. This model provides flexibility, allowing businesses to utilize various warehouses based on their needs while optimizing warehouse utilization rates.

A key benefit of portal warehousing is the ability to scale warehousing needs up or down seamlessly. This flexibility is particularly advantageous for businesses experiencing seasonal demand fluctuations, as it eliminates the need for long-term leases or contracts. Additionally, portal warehousing can significantly reduce overall warehousing costs by leveraging shared spaces, enabling economies of scale, and offering value-added services such as inventory management and order fulfillment.

For more insights on portal warehousing, refer to the ShipScience Portal Warehousing Benefits page.

Advantages and Benefits of Outsourcing to a 3PL Company

- Cost Savings: Outsourcing to a 3PL provider can reduce overhead costs related to warehousing, transportation, and labor.

- Increased Speed and Efficiency: 3PLs leverage their expertise and technology to streamline logistics processes, resulting in faster order fulfillment.

- Access to Advanced Technologies: 3PL providers utilize state-of-the-art technologies such as Warehouse Management Systems (WMS) and Transportation Management Systems (TMS) to enhance supply chain efficiencies.

- Scalability and Flexibility: As businesses grow or face seasonal demands, 3PL providers can adjust logistics services to meet changing needs.

- Focus on Core Competencies: Outsourcing logistics allows businesses to concentrate on their core activities, such as product development and marketing.

According to a Forbes article (2023), companies that outsource logistics to 3PL providers can achieve up to a 20% reduction in logistics costs while improving service levels.

Key Features and Technological Innovations in 3PL and Portal Warehousing

3PL companies play a pivotal role in optimizing supply chain management by streamlining processes, reducing costs, and enhancing customer service. They employ advanced technologies like Transportation Management Systems (TMS) and Warehouse Management Systems (WMS) to track shipments accurately, manage inventory levels, and optimize delivery routes.

Moreover, 3PL providers offer contingency plans to mitigate risks associated with supply chain disruptions, ensuring business continuity. Their expertise in navigating complex regulations and compliance requirements is invaluable, especially for businesses involved in international trade. 3PL providers assist in adhering to customs regulations and facilitate smooth cross-border shipments, minimizing delays and avoiding costly penalties.

Key features of 3PL logistics fulfillment and portal warehousing include:

- Order Management: Efficient handling of order processing, tracking, and fulfillment.

- Inventory Management: Real-time tracking and management of inventory levels to prevent stockouts and overstocking.

- Warehouse Management: Optimized storage solutions and efficient use of warehouse space.

- Customer Service: Enhanced customer support through timely and accurate order fulfillment.

- Transportation Management: Streamlined shipping processes and optimized delivery routes.

3PL providers and portal warehouse operators utilize advanced IT systems to automate and optimize these processes. Additionally, they maintain strong relationships with suppliers, carriers, and other supply chain stakeholders to reduce risks and enhance performance.

Customization is another crucial feature, allowing businesses to tailor packaging, labeling, and shipping options to meet their unique requirements. Value-added services such as kitting, assembly, and quality control further streamline operations and boost efficiency.

For more information on the key features, visit the ShipScience 3PL Features page.

Selecting the Right 3PL Provider

Choosing the right 3PL logistics provider is crucial for optimizing your supply chain and ensuring business success. Here are some essential tips:

- Experience and Expertise: Select a provider with a proven track record and industry-specific knowledge.

- Reputation: Research reviews and testimonials to gauge the provider’s reliability and quality of service.

- Technology Capabilities: Ensure the provider utilizes advanced technologies that integrate seamlessly with your existing systems.

- Flexibility and Scalability: Choose a provider that can adapt to your business’s changing needs.

- Geographic Reach: Consider whether the provider has a strong presence in the regions where you operate or plan to expand.

- Customer Support: Evaluate the level of support and communication offered by the provider.

Additionally, assess the provider’s ability to handle your specific logistics requirements and their capacity to scale operations as your business grows. It’s essential to partner with a 3PL provider that aligns with your business goals and can support your expansion into new markets.

For a detailed guide on selecting the right 3PL provider, visit the ShipScience Choosing a 3PL Provider page.

Case Studies: Success with 3PL and Portal Warehousing

Numerous businesses have successfully leveraged 3PL logistics fulfillment and portal warehousing to enhance supply chain efficiencies and reduce costs. For instance, PepsiCo outsourced its entire logistics and supply chain operations to 3PL provider Ryder, resulting in a 22% reduction in logistics costs and improving order accuracy levels to 99%. This partnership allowed PepsiCo to focus on its core business functions while Ryder optimized its supply chain processes.

Similarly, Zara utilizes portal warehousing to optimize logistics and minimize inventory costs. By accessing a network of shared warehouses, Zara achieves faster delivery times and reduces inventory carrying costs. This strategic approach enables Zara to maintain its competitive edge in the fast-fashion industry by ensuring timely product availability and efficient inventory management.

Another example is Amazon, which partners with multiple 3PL providers to manage its vast distribution network. This collaboration allows Amazon to handle high order volumes, especially during peak seasons, while maintaining high customer satisfaction through reliable and swift delivery services.

Read more success stories and case studies on the ShipScience Case Studies page.

Common Challenges in Outsourcing Logistics to a 3PL Provider

While outsourcing logistics to a 3PL provider offers numerous benefits, it also presents certain challenges. One of the most significant concerns is the potential loss of control over logistics operations. Businesses must ensure that their chosen provider fully understands their requirements and can meet them consistently.

Another challenge is the integration of systems and processes. Seamless integration between a business’s internal systems and the 3PL provider’s IT platforms is crucial for efficient communication and coordination. Any discrepancies can lead to delays, errors in order fulfillment, and inventory management issues.

Additionally, there may be hidden costs associated with outsourcing, such as fees for additional services or penalties for not meeting certain performance metrics. It is essential to thoroughly review contracts and understand all potential costs before entering into an agreement with a 3PL provider.

To mitigate these challenges, businesses should conduct thorough due diligence when selecting a 3PL provider, establish clear communication channels, and set measurable performance standards. Building a strong partnership based on trust and transparency is key to overcoming potential obstacles.

For strategies to address common outsourcing challenges, visit the ShipScience Outsourcing Challenges page.

Future Trends and Sustainability in 3PL Logistics

The future of 3PL logistics fulfillment and portal warehousing is poised for significant growth and innovation, influenced by several emerging trends:

- Integration of Emerging Technologies: Adoption of AI, robotics, and blockchain will continue to enhance efficiency, accuracy, and transparency in logistics and warehousing operations.

- Sustainability: There is a growing emphasis on sustainable practices, with businesses aiming to reduce their carbon footprint through green logistics and eco-friendly warehousing solutions.

- E-commerce and Omnichannel Logistics: The rise of e-commerce and the demand for omnichannel fulfillment strategies are driving changes in logistics practices, necessitating more flexible and scalable 3PL solutions.

- Data Analytics: Enhanced data analytics capabilities will enable businesses to gain deeper insights into their supply chains, facilitating better decision-making and optimization.

- Automation and Robotics: Increased use of automation and robotics in warehouses will streamline operations, reduce labor costs, and improve accuracy.

Staying abreast of these trends will be crucial for businesses looking to leverage 3PL logistics fulfillment and portal warehousing to maintain a competitive edge.

Explore future trends in logistics on the ShipScience Future Trends page.

How Sustainable Practices are Impacting the 3PL Industry

Environmental sustainability is becoming an increasingly critical focus for businesses, consumers, and governments worldwide. In response, companies are adopting sustainable practices across their supply chains, including logistics and warehousing operations. Many 3PL providers are enhancing their sustainability credentials by implementing green practices such as utilizing renewable energy sources, reducing waste, and minimizing their carbon footprint.

Key sustainable practices in the 3PL industry include:

- Energy-Efficient Warehousing: Implementing energy-saving technologies like LED lighting, solar panels, and energy-efficient HVAC systems.

- Green Transportation: Utilizing electric or hybrid vehicles for transportation, optimizing routes to reduce fuel consumption, and implementing driver training programs focused on eco-friendly driving techniques.

- Waste Reduction: Minimizing packaging waste through recyclable materials and efficient packaging designs, as well as implementing recycling programs within warehouses.

- Carbon Offsetting: Investing in carbon offset projects to balance out emissions generated by logistics activities.

Adopting sustainable practices not only helps reduce environmental impact but also enhances a company's reputation and can lead to cost savings in the long run. According to a McKinsey report (2023), companies that prioritize sustainability in their logistics operations can achieve up to a 15% reduction in operational costs.

Learn more about sustainable logistics practices on the ShipScience Sustainable Logistics page.

How Technology is Revolutionizing 3PL Logistics Fulfillment and Portal Warehousing

The logistics and warehousing industries are undergoing rapid transformation, driven by technological advancements. E-commerce fulfillment has become a critical aspect, requiring fast and accurate order processing. Technologies such as robotics and automation are enhancing efficiencies, with autonomous mobile robots (AMRs) and automated storage and retrieval systems (AS/RS) playing significant roles in reducing operational costs.

Emerging technologies like artificial intelligence (AI), blockchain, and the Internet of Things (IoT) are also revolutionizing logistics and warehousing. For instance, AI-powered predictive analytics can forecast demand and optimize inventory levels, while blockchain ensures transparency and security in supply chain transactions.

Real-time inventory tracking is another major benefit, enabled by IoT sensors and RFID tags. This capability reduces the risk of lost or stolen goods and allows businesses to optimize inventory management, minimizing waste and improving overall efficiency.

Discover more about how technology is transforming logistics on the ShipScience Technology in 3PL page.

How 3PL Companies Can Help You Streamline Your Supply Chain Management

3PL companies play a pivotal role in optimizing supply chain management by streamlining processes, reducing costs, and enhancing customer service. They employ advanced technologies like Transportation Management Systems (TMS) and Warehouse Management Systems (WMS) to track shipments accurately, manage inventory levels, and optimize delivery routes.

Moreover, 3PL providers offer contingency plans to mitigate risks associated with supply chain disruptions, ensuring business continuity. Their expertise in navigating complex regulations and compliance requirements is invaluable, especially for businesses involved in international trade. 3PL providers assist in adhering to customs regulations and facilitate smooth cross-border shipments, minimizing delays and avoiding costly penalties.

For more detailed information on how 3PL companies enhance supply chain management, visit the ShipScience Supply Chain Solutions page.

The Advantages of Using a Portal Warehouse for Your Business Operations

- Cost Efficiency: Avoid high capital expenditure by paying only for the storage space used.

- Flexibility: Access multiple warehouses as needed, optimizing logistics networks and increasing delivery speed.

- Scalability: Easily scale storage space up or down based on business demands without long-term commitments.

- Optimized Logistics: Utilize strategically located warehouses to reduce transportation costs and improve delivery times.

Portal warehousing enables businesses to respond swiftly to market changes and maintain competitiveness. By leveraging shared warehouse spaces, companies can optimize their logistics operations and enhance overall efficiency.

Learn more about the benefits of portal warehousing on the ShipScience Portal Warehousing Benefits page.