Innovative Warehouse Solutions and Their Features for 3PL Logistics Fulfillment

As the logistics industry evolves rapidly, third-party logistics (3PL) companies are continuously seeking ways to enhance efficiency and maintain a competitive edge. Implementing innovative warehouse solutions is a key strategy to achieve these goals. In this article, we delve into various warehouse solutions that aid 3PL companies in optimizing operations and elevating fulfillment services for their customers. From understanding the challenges of 3PL logistics fulfillment to selecting the ideal warehouse management system (WMS), we provide comprehensive insights backed by industry data.

Industry Insights

According to a report by Statista, the global 3PL market is projected to reach over $1.2 trillion by 2025, highlighting the critical role of advanced warehouse solutions in sustaining growth and efficiency.

Understanding the Current Challenges of 3PL Logistics Fulfillment

Before exploring solutions, it's essential to comprehend the challenges that 3PL companies encounter in their fulfillment operations:

- High Delivery Expectations: Customers demand faster and more accurate deliveries. According to a Forbes report, 75% of consumers expect same-day or next-day delivery.

- Inventory Management: Balancing inventory levels is crucial. Overstocking increases costs and risks, while understocking leads to stockouts and lost sales.

- Technological Advancements: Keeping up with the latest warehouse management systems and automation technologies is vital for maintaining competitiveness.

- International Shipping Complexities: Navigating global shipping laws and customs regulations requires significant resources and expertise, posing challenges especially for smaller 3PL firms.

Introduction to Warehouse Management Systems (WMS)

A warehouse management system (WMS) is a software application designed to oversee and streamline warehouse operations. By automating processes such as inventory management, order picking, packing, and shipping, WMS enhances efficiency and reduces operational costs. According to a definition by Investopedia, a robust WMS provides real-time visibility into inventory levels and movement, enabling better decision-making and resource allocation.

Key features of WMS include:

- Real-Time Inventory Tracking: Offers up-to-date information on stock levels, locations, and movements.

- Order Fulfillment Optimization: Streamlines picking, packing, and shipping processes to enhance accuracy and speed.

- Integration Capabilities: Seamlessly connects with other systems like Transportation Management Systems (TMS) and Enterprise Resource Planning (ERP) for cohesive operations.

Advantages of Implementing WMS for 3PL Warehouses

Implementing a WMS offers numerous benefits for 3PL companies:

- Increased Efficiency: Streamlines warehouse processes, reducing time and effort required for tasks.

- Improved Inventory Accuracy: Minimizes errors through automated data entry and tracking.

- Enhanced Customer Service: Facilitates faster and more accurate order fulfillment, leading to higher customer satisfaction.

- Space Optimization: Provides insights into space utilization, allowing for better layout planning and cost savings.

- Regulatory Compliance: Assists in adhering to industry regulations related to product labeling and tracking.

According to a study by Warehouse Management.com, companies that implement WMS see an average increase of 12% in operational efficiency.

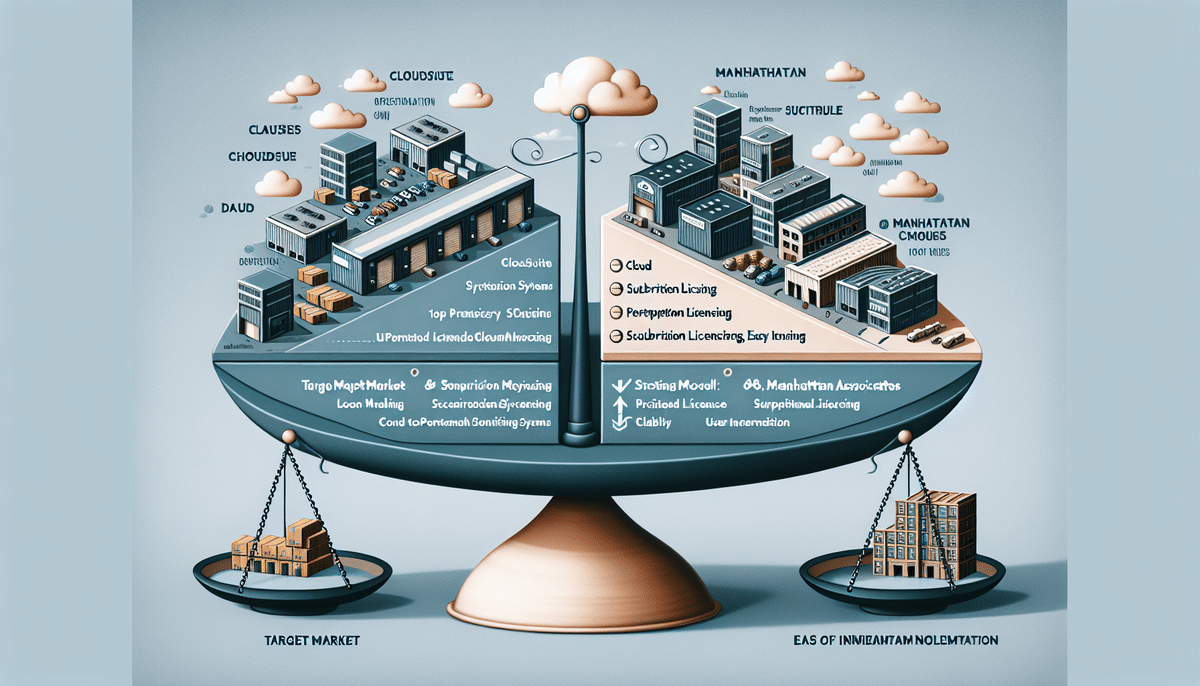

Different Types of WMS and How to Choose the Right One for Your Business

Choosing the right WMS is pivotal for aligning with your business needs. The primary types include:

- Standalone WMS: A dedicated software solution focused solely on warehouse management.

- ERP-Based WMS: Integrated within an Enterprise Resource Planning system, offering additional functionalities like accounting and human resources.

- Cloud-Based WMS: Accessible via the internet, allowing for quick implementation and scalability.

- Mobile-Based WMS: Utilizes mobile devices for managing inventory and tracking shipments, ideal for large or distributed warehouses.

When selecting a WMS, consider factors such as:

- Business Requirements: Assess your specific needs and operational complexities.

- Scalability: Ensure the WMS can grow with your business, accommodating increased inventory and transactions.

- Integration: Verify compatibility with existing systems like TMS and ERP.

- Budget: Balance the features offered with your financial constraints.

Benefits of Automated Storage and Retrieval Systems (AS/RS) in Warehousing

Automated Storage and Retrieval Systems (AS/RS) utilize robotics and automation technologies to handle the storage and retrieval of goods. These systems enhance warehouse efficiency through:

- Increased Storage Density: Maximizes space utilization by optimizing storage layouts.

- Higher Efficiency: Accelerates the storage and retrieval processes, reducing manual labor.

- Improved Inventory Accuracy: Minimizes errors through automated tracking and handling.

- Enhanced Safety: Reduces workplace accidents by minimizing human interaction with heavy machinery.

Implementing AS/RS can lead to significant cost savings and operational improvements. According to McKinsey & Company, warehouses leveraging AS/RS report a 30% increase in productivity.

How Robotics is Revolutionizing 3PL Logistics Fulfillment

Robotics technology is transforming 3PL logistics fulfillment by automating repetitive tasks and enhancing operational accuracy. Key applications include:

- Automated Guided Vehicles (AGVs): Transport goods within the warehouse without human intervention.

- Robotic Arms: Handle tasks such as picking, packing, and sorting with precision and speed.

- Collaborative Robots (Cobots): Work alongside human employees to increase productivity and reduce labor costs.

Benefits of integrating robotics into warehouse operations:

- Increased Throughput: Robots can operate continuously, significantly boosting order processing rates.

- Reduced Labor Costs: Automation lowers reliance on manual labor, leading to cost savings.

- Enhanced Safety: Robots handle hazardous tasks, reducing workplace injuries.

- Real-Time Data and Analytics: Provide insights into operational performance, enabling data-driven decision-making.

According to Robotics Business Review, warehouses utilizing robotics have seen a 25% reduction in order fulfillment times.

Exploring the Role of Artificial Intelligence (AI) in Warehouse Automation

Artificial Intelligence (AI) is increasingly integral to warehouse automation, offering advanced capabilities such as:

- Demand Forecasting: Predicts inventory requirements based on historical data and market trends.

- Inventory Management: Optimizes stock levels and placement within the warehouse.

- Product Recommendations: Enhances cross-selling and upselling strategies based on customer behavior.

AI-driven systems can significantly reduce errors and enhance efficiency by automating repetitive tasks. For instance, AI-powered picking systems can adapt in real-time to changing order patterns, ensuring optimal performance.

Furthermore, AI facilitates predictive maintenance of warehouse equipment, minimizing downtime and extending asset lifespan. As reported by Forbes, warehouses implementing AI technologies have experienced a 20% increase in operational efficiency.

The Importance of Data Analytics in Optimizing Warehouse Operations

Data analytics plays a pivotal role in optimizing warehouse operations by providing actionable insights. Key areas where data analytics contributes include:

- Inventory Optimization: Analyzes stock levels and turnover rates to maintain optimal inventory.

- Order Processing: Identifies bottlenecks and streamlines workflows to enhance order fulfillment speed.

- Demand Planning: Utilizes historical data to forecast future demand, aiding in strategic decision-making.

- Performance Monitoring: Tracks key performance indicators (KPIs) to assess and improve operational efficiency.

Leveraging data analytics enables 3PL companies to make informed decisions, reduce costs, and improve customer satisfaction. According to a Datamation article, businesses that harness data analytics in their logistics operations see a 15% improvement in delivery performance.

Implementing Cloud-Based Solutions for Improved Warehouse Management

Cloud-based solutions offer significant advantages for warehouse management, including:

- Scalability: Easily scales with business growth, accommodating increased inventory and transaction volumes.

- Accessibility: Accessible from anywhere, facilitating remote management and real-time updates.

- Cost-Effectiveness: Reduces the need for on-premises infrastructure, lowering IT expenses.

- Enhanced Collaboration: Improves communication between suppliers, customers, and other stakeholders through centralized data access.

Adopting cloud-based WMS enables 3PL companies to respond swiftly to market changes and customer demands. According to a Gartner report, the adoption of cloud-based WMS has increased by 35% over the past year.

Evaluating the Benefits of Voice-Picking Technology in Warehousing

Voice-picking technology enhances warehouse operations by using voice commands to guide workers through the picking process. Benefits include:

- Increased Accuracy: Reduces errors by providing clear, hands-free instructions.

- Faster Picking Times: Speeds up the picking process by allowing workers to operate more efficiently.

- Reduced Training Time: Simplifies training by providing intuitive, voice-based guidance.

- Enhanced Ergonomics: Minimizes the need for handheld devices, reducing physical strain on workers.

Studies by Warehouse Management.com indicate that voice-picking systems can improve picking accuracy by up to 99.9% and increase productivity by 30%.

The Role of Internet of Things (IoT) in Enhancing Warehouse Efficiency

The Internet of Things (IoT) connects devices and systems within the warehouse, enabling seamless communication and data exchange. Key applications of IoT in warehousing include:

- Smart Sensors: Monitor environmental conditions and equipment status in real-time.

- RFID Tags: Provide accurate tracking of inventory movement and location.

- Asset Tracking: Ensures the efficient utilization and maintenance of warehouse assets.

- Predictive Maintenance: Anticipates equipment failures before they occur, minimizing downtime.

Implementing IoT solutions leads to enhanced operational visibility and efficiency. According to i-Scoop, warehouses utilizing IoT technologies have reported a 25% improvement in operational efficiency and a 20% reduction in maintenance costs.

Best Practices for Integrating Innovative Solutions into 3PL Logistics Fulfillment

Successfully integrating innovative warehouse solutions into 3PL logistics fulfillment requires a strategic approach:

- Assess Current Operations: Conduct a thorough evaluation of existing processes to identify areas for improvement.

- Define Clear Objectives: Establish specific goals that align with your business strategy.

- Select Appropriate Solutions: Choose technologies that address identified challenges and support your objectives.

- Provide Comprehensive Training: Ensure that employees are adequately trained to use new technologies effectively.

- Implement Gradually: Roll out new solutions in phases to manage change smoothly and minimize disruptions.

- Monitor and Evaluate: Continuously track the performance of implemented solutions and make necessary adjustments.

Adopting these best practices facilitates a seamless transition to advanced warehouse solutions, ensuring sustained operational improvements and enhanced fulfillment services.

Key Considerations When Selecting a Technology Partner for Your Warehouse Operations

Choosing the right technology partner is crucial for the success of your warehouse operations. Key considerations include:

- Experience and Expertise: Assess the partner’s track record and expertise in warehouse management and logistics solutions.

- Scalability: Ensure the partner can provide scalable solutions that grow with your business needs.

- Integration Capabilities: Verify that the partner’s technologies can seamlessly integrate with your existing systems.

- Customer Support: Evaluate the quality and responsiveness of the partner’s customer support services.

- Reputation: Consider the partner’s reputation in the industry, backed by client testimonials and case studies.

Partnering with a reliable technology provider ensures that your warehouse operations are supported by robust, scalable, and efficient solutions. According to TechRepublic, companies that select the right technology partners experience a 40% increase in operational efficiency.

In conclusion, implementing innovative warehouse solutions can significantly enhance the operations of 3PL companies by reducing costs, improving efficiency, and elevating customer service. From advanced warehouse management systems to robotics, AI, and IoT, a wide array of technologies is available to help 3PL companies stay competitive in a rapidly evolving market.