Understanding Pick and Pack Fulfillment: A Comprehensive Guide

If you operate a business selling physical products, you're likely familiar with the challenges of order fulfillment. Pick and pack fulfillment is a crucial process in shipping and delivering products to customers. It involves selecting individual items from inventory, packaging them, and labeling them for shipment. The speed and accuracy of this process significantly impact customer satisfaction and overall business success.

What is Pick and Pack Fulfillment and How Does It Work?

Pick and pack fulfillment involves preparing individual items for shipment to customers. The process typically includes:

- Picking: Selecting items from inventory based on customer orders.

- Verifying: Ensuring the accuracy of the selected items.

- Packing: Packaging items into appropriate containers.

- Labeling: Preparing shipments with correct labels for delivery.

Depending on the size and complexity of the operation, this process can be performed manually or through automated systems. According to a Statista report, e-commerce sales in the US alone are projected to reach $1.3 trillion by 2024, highlighting the growing importance of efficient fulfillment processes.

One key benefit of pick and pack fulfillment is the efficient management of inventory and shipping processes. By outsourcing this task to a third-party logistics provider (3PL), companies can focus on other business aspects such as marketing and sales. Additionally, pick and pack fulfillment can help businesses save on shipping costs by consolidating orders and utilizing more efficient shipping methods.

However, it's crucial to choose a reliable and experienced pick and pack fulfillment provider to ensure orders are accurately fulfilled and shipped on time. Communication and transparency are also essential, as businesses need to track inventory and shipments in real-time. Overall, pick and pack fulfillment can be a valuable solution for businesses looking to streamline operations and enhance the customer experience.

The Importance of Efficient Pick and Pack Fulfillment in Business Success

The efficiency of pick and pack fulfillment operations significantly impacts customer satisfaction and overall business success. Efficient and accurate order fulfillment can lead to:

- Increased Sales: Fast fulfillment can encourage repeat purchases.

- Customer Loyalty: Reliable delivery builds trust with customers.

- Positive Reviews: Satisfied customers are more likely to leave favorable feedback.

Conversely, slow and inaccurate fulfillment can result in customer dissatisfaction, negative reviews, and lost sales. Therefore, optimizing pick and pack fulfillment processes is vital for businesses.

One way to optimize pick and pack fulfillment is by implementing technology such as automated picking systems and barcode scanning. These technologies can improve accuracy and speed up the fulfillment process, reducing the likelihood of errors and delays. Additionally, businesses can consider outsourcing their fulfillment operations to third-party logistics providers specializing in pick and pack services. This can free up internal resources and allow businesses to focus on other operational areas while ensuring efficient and accurate order fulfillment.

Top Benefits of Using Pick and Pack Fulfillment for Your Business

Using pick and pack fulfillment offers several benefits for your business:

- Cost Savings: Outsourcing pick and pack fulfillment can save businesses money on labor, equipment, and storage costs, as well as provide access to discounted shipping rates.

- Increased Efficiency: Automated pick and pack fulfillment can significantly increase the speed and accuracy of the process, resulting in faster order fulfillment and reduced errors.

- Scalability: Pick and pack fulfillment services can easily scale up or down to accommodate changing business needs without requiring significant investments in infrastructure or personnel.

- Improved Customer Satisfaction: Efficient and accurate order fulfillment can lead to increased customer satisfaction and retention, as well as positive word-of-mouth marketing.

- Expanded Product Offerings: By outsourcing the fulfillment process, businesses can offer a wider range of products without worrying about the logistics of storing and shipping those products themselves.

- Advanced Inventory Management: Pick and pack fulfillment services often provide advanced inventory management systems, helping businesses track stock levels and avoid stockouts, especially during peak seasons or product launches.

Incorporating these benefits can significantly enhance your business operations and customer relationships.

Common Challenges in Pick and Pack Fulfillment and How to Overcome Them

Businesses face several common challenges in pick and pack fulfillment:

- Inventory Management: Maintaining accurate inventory levels requires regular tracking and demand forecasting. Businesses can address this by using inventory management software and conducting regular audits.

- Poor Warehouse Design: Inefficient warehouse layouts can lead to disrupted workflows and increased error rates. Optimizing warehouse layouts and investing in appropriate equipment and technology can mitigate this issue.

- Human Error: Manual pick and pack processes are prone to human error, leading to order inaccuracies and increased costs. Utilizing automation, such as barcode scanners and conveyor systems, can reduce the risk of human error.

- Shipping Delays: Shipping delays can occur due to various reasons, such as carrier issues, weather conditions, or incorrect shipping information. To overcome this challenge, businesses can work with reliable carriers, provide accurate shipping information, and have contingency plans for unexpected delays.

Implementing robust systems and choosing the right partners can help businesses navigate these challenges effectively.

Key Factors to Consider When Choosing a Pick and Pack Fulfillment Service Provider

When selecting a pick and pack fulfillment service provider, businesses should consider several factors:

- Experience: Look for a provider with a proven track record and experience in your industry.

- Technology: Ensure the provider utilizes up-to-date technology and automation systems for accuracy and efficiency.

- Location: Consider the provider's location relative to your customers and shipping destinations, as it can affect shipping times and costs.

- Costs: Compare costs and pricing structures among multiple providers to ensure you receive the best value for your investment.

- Flexibility: Seek providers that offer scalable services to accommodate your changing business needs.

- Customer Service: Choose a provider with a responsive and helpful customer service team. Effective communication channels like phone, email, and live chat are essential for resolving issues promptly.

Evaluating these factors will help you select a fulfillment partner that aligns with your business goals and customer expectations.

Best Practices for Effective Pick and Pack Fulfillment Management

To ensure efficient and accurate pick and pack fulfillment, businesses should implement several best practices:

- Invest in Automation: Automated systems like barcode scanners and conveyor belts can significantly boost speed and accuracy.

- Train Employees: Proper training on pick and pack fulfillment processes and equipment is essential, along with regular refresher courses.

- Optimize Inventory Management: Utilize inventory management software and conduct regular audits to maintain accurate inventory levels and minimize errors.

- Implement Quality Control Measures: Regularly check orders for accuracy and address any errors or discrepancies promptly.

- Prioritize Workplace Safety: Provide employees with proper safety equipment, ensure all equipment is regularly inspected and maintained, and establish clear safety protocols.

Prioritizing these practices not only enhances operational efficiency but also ensures a safe and productive work environment.

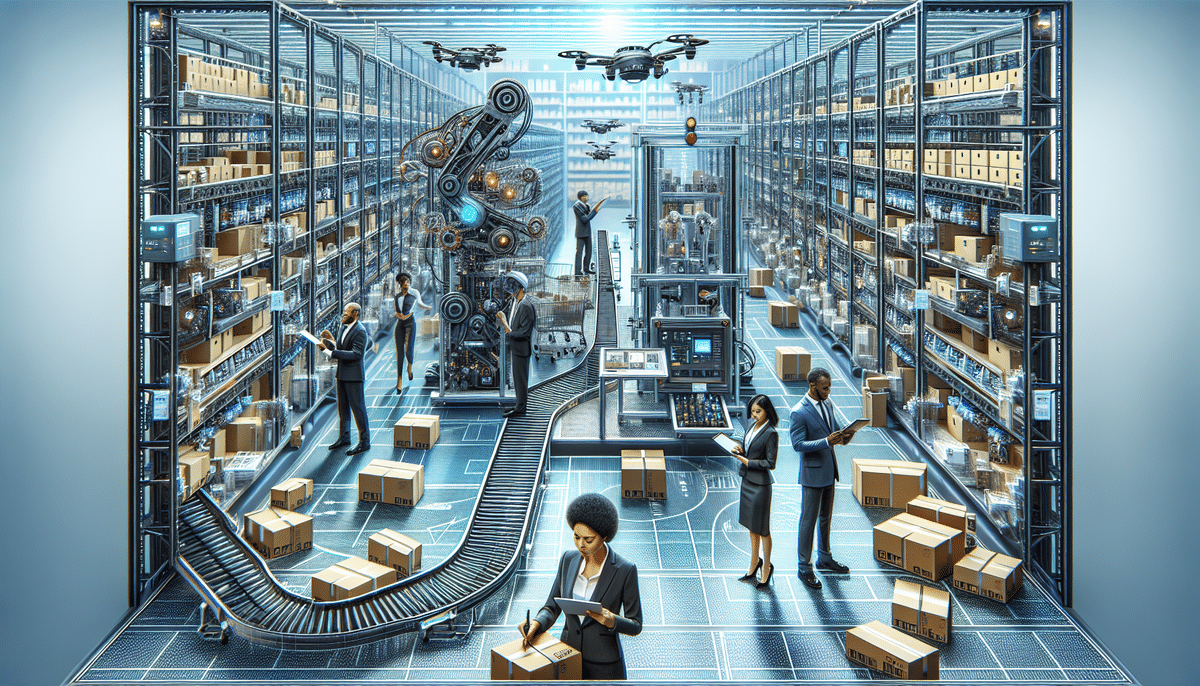

The Role of Technology in Streamlining Pick and Pack Fulfillment Processes

Technology plays a critical role in enhancing the efficiency and accuracy of pick and pack fulfillment operations. Some of the key technologies used include:

- Barcode Scanners: Scanning barcodes on products and shipments significantly reduces errors and speeds up the process.

- Conveyor Systems: Automated conveyor systems transport products to different warehouse areas, improving efficiency and reducing labor costs.

- Warehouse Management Software: Tools such as inventory management, order tracking, and quality control software help businesses manage pick and pack fulfillment processes more effectively.

- Robotics and Automation: Advanced robotics can handle repetitive tasks, increasing speed and precision.

- Artificial Intelligence: AI can optimize picking routes, predict demand, and manage inventory levels more accurately.

Integrating these technologies can lead to significant improvements in fulfillment speed, accuracy, and overall operational efficiency.

Optimizing Your Pick and Pack Fulfillment Strategy for Cost Savings

Businesses can optimize their pick and pack fulfillment strategies to achieve cost savings. Consider the following strategies:

- Outsourcing: Outsourcing pick and pack fulfillment can reduce labor and infrastructure costs, and provide access to discounted shipping rates.

- Automating: Implementing automated systems like conveyor belts and barcode scanners can lower labor costs and increase efficiency.

- Consolidating Orders: Combining orders into larger shipments can reduce shipping costs and enhance efficiency.

- Optimizing Warehouse Layout: Designing warehouse layouts for efficient workflows can reduce labor costs and improve productivity.

- Inventory Optimization: Maintain optimal inventory levels to avoid overstocking and stockouts, thereby reducing holding costs.

Implementing these strategies can help businesses minimize costs while maintaining high levels of service and efficiency.

Measuring the Success of Your Pick and Pack Fulfillment Operations: Key KPIs to Track

It's important for businesses to measure and track the success of their pick and pack fulfillment operations to identify areas for improvement. Key performance indicators (KPIs) to consider include:

- Order Accuracy: The percentage of orders that are accurately picked and packed.

- Order Cycle Time: The time it takes to complete the entire order cycle, including picking, packing, and shipping.

- Inventory Accuracy: The percentage of inventory that is accurately tracked and accounted for.

- Cycle Count Variance: The difference between actual inventory levels and expected levels, as determined by regular cycle counts.

- Shipping Time: The average time taken from order placement to delivery.

- Return Rate: The percentage of orders that are returned due to fulfillment errors.

Regularly monitoring these KPIs can provide valuable insights into the efficiency and effectiveness of your fulfillment operations, allowing for data-driven improvements.

Future Trends in Pick and Pack Fulfillment: What to Expect in the Coming Years

As technology continues to advance, the pick and pack fulfillment industry is likely to see several trends, including:

- Growth in E-commerce: The rise of e-commerce is expected to drive increased demand for pick and pack fulfillment services. According to eMarketer, global e-commerce sales are projected to continue their upward trajectory, necessitating more efficient fulfillment solutions.

- Further Automation: Automation, including robotics and artificial intelligence, will likely increase in pick and pack processes, enhancing efficiency and accuracy.

- Increased Emphasis on Sustainability: With growing environmental concerns, more businesses will focus on sustainability in pick and pack fulfillment, such as using eco-friendly packaging materials and optimizing shipping routes to reduce carbon footprints.

- Omnichannel Fulfillment: Integrating online and offline sales channels to provide seamless customer experiences will become increasingly important.

- Enhanced Data Analytics: Utilizing big data and analytics to optimize inventory management, predict demand, and improve fulfillment strategies.

Staying abreast of these trends will help businesses adapt and remain competitive in the evolving fulfillment landscape.

Case Studies: Real-Life Examples of Successful Pick and Pack Fulfillment Strategies

Several businesses have implemented effective pick and pack fulfillment strategies to achieve success:

- Amazon: Amazon's use of advanced automation systems, including robots and conveyor belts, has enabled fast and accurate order fulfillment. Their investment in fulfillment center technology sets a benchmark in the industry.

- Warby Parker: Warby Parker's efficient warehouse layouts and inventory management software have allowed rapid scaling of their pick and pack fulfillment processes, ensuring timely delivery to customers.

- Zappos: Zappos' focus on customer experience and a culture of service has resulted in fast and accurate order fulfillment and high customer satisfaction. Their commitment to excellent customer service is well-documented.

These examples demonstrate how strategic fulfillment practices can drive business growth and customer loyalty.

Conclusion

Pick and pack fulfillment is a critical process for any business selling physical products. An efficient and accurate pick and pack fulfillment process can lead to increased customer satisfaction, sales, and overall business success. By implementing best practices, leveraging technology, and tracking key performance indicators, businesses can optimize their pick and pack fulfillment strategies and stay competitive in the marketplace.