Critical KPIs for Inventory Management: What You Need to Monitor

Inventory management is a crucial aspect of any business dealing with physical products. Whether you operate a small retail store or a large manufacturing facility, effective inventory management can significantly impact your profitability. Monitoring the right Key Performance Indicators (KPIs) is essential for achieving optimal results. In this article, we will explore the most critical KPIs for inventory management and explain why they are vital for your business's success.

Understanding the Basics of Inventory Management

Before delving into KPIs, it's essential to understand the fundamentals of inventory management. At its core, inventory management involves overseeing the flow of goods in and out of your business. This includes activities such as ordering and receiving products, tracking sales, and maintaining stock levels.

The primary goal of inventory management is to maintain the right balance of stock. Excess inventory ties up capital and increases storage costs, while insufficient inventory can lead to lost sales and dissatisfied customers. Achieving this balance requires a deep understanding of supply and demand dynamics and the various factors that influence inventory levels.

One key factor affecting inventory levels is seasonality. For example, a clothing store may need to stock up on winter coats in the fall, but those same coats may not sell as well in the spring. Understanding seasonal trends and adjusting inventory levels accordingly can help businesses avoid overstocking or understocking.

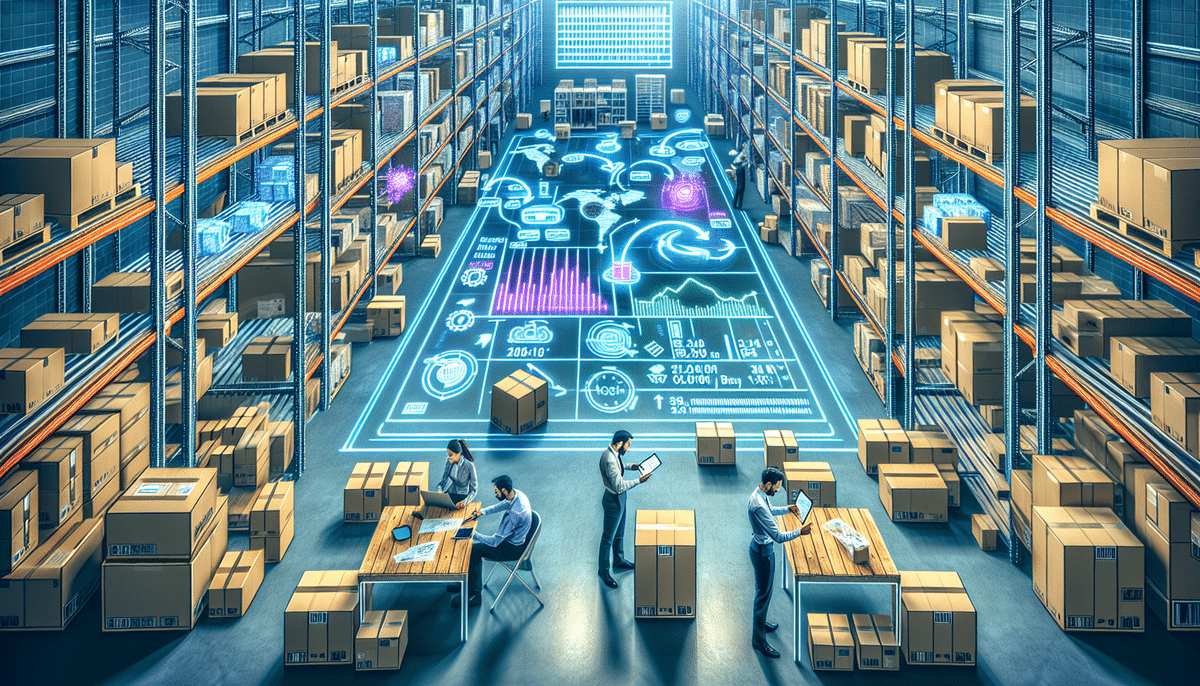

Another critical aspect of inventory management is the use of technology. Inventory management software can help businesses track inventory levels in real-time, automate reordering processes, and provide valuable insights into sales trends and customer behavior. Investing in the right technology can streamline inventory management processes and improve overall efficiency. According to a Statista report, businesses utilizing advanced inventory management systems experience a 20% increase in operational efficiency.

The Importance of Monitoring KPIs in Inventory Management

To effectively manage inventory, establishing KPIs that help track progress and identify areas for improvement is crucial. KPIs provide valuable insights into the performance of your inventory management processes, supporting data-driven decision-making.

Monitoring KPIs allows you to identify potential issues early and take corrective actions before they escalate. For instance, if your lead times are increasing, you can adjust your ordering processes to ensure sufficient stock levels to meet demand. Additionally, tracking KPIs enables you to measure the success of changes or improvements made to your inventory management strategies.

Another significant benefit of monitoring KPIs is optimizing inventory levels. By tracking metrics such as inventory turnover rate and stockout rate, you can determine the optimal amount of inventory to maintain. This helps prevent overstocking, which ties up capital and raises storage costs, or understocking, which can lead to lost sales and customer dissatisfaction.

The Top KPIs to Monitor for Effective Inventory Management

While there are numerous KPIs to track for inventory management, some are more critical than others. Here are the top KPIs you should monitor to achieve effective inventory management:

1. Inventory Turnover

Inventory turnover measures the number of times you sell and replace your inventory within a specific period. A high inventory turnover rate indicates efficient sales and inventory management, while a low rate suggests potential issues with demand or inventory processes. Industry standards recommend aiming for a turnover rate between 4 to 6 times annually, depending on the sector.

2. Order Cycle Time

Order cycle time measures the duration from when a customer places an order to when the product is delivered. Shorter order cycle times enhance customer satisfaction and can lead to repeat business. According to a Forbes Technology Council study, companies that reduced their order cycle times by 15% saw a 10% increase in customer retention.

3. Lead Time

Lead time measures the period it takes to receive products after placing an order with suppliers. Shorter lead times enable quicker responses to changes in demand or unexpected supply chain disruptions, enhancing overall agility.

4. Stock Accuracy

Stock accuracy measures the percentage of your inventory that is accurately recorded in your system. Poor stock accuracy can lead to stockouts or excess inventory, adversely affecting profitability. Striving for over 95% accuracy is recommended for optimal performance.

5. Carrying Costs

Carrying costs refer to the expenses associated with holding inventory, such as storage, insurance, and depreciation. Monitoring carrying costs helps identify opportunities to reduce expenses and optimize inventory levels. Industry research indicates that reducing carrying costs by 10% can result in a 5% increase in overall profitability.

Identifying and Measuring Key Performance Indicators (KPIs) for Inventory Management

Identifying and measuring KPIs for inventory management requires a systematic approach:

- Define Goals: Identify specific objectives you want to achieve with your inventory management processes, such as reducing stockouts or minimizing carrying costs.

- Select Relevant KPIs: Determine which KPIs provide the information needed to monitor progress toward your goals.

- Implement Tracking Systems: Use inventory management software, spreadsheets, or custom reports to track your selected KPIs accurately.

- Regular Review: Consistently analyze KPI data to identify trends, areas for improvement, and measure the impact of any changes implemented.

Implementing a robust tracking system ensures you have access to accurate and timely data to make informed decisions. Tools like Oracle Inventory Management offer comprehensive tracking capabilities.

Real-time Tracking: The Key to Inventory Optimization

Real-time tracking is essential for effective inventory optimization. It allows you to monitor inventory levels, sales, and other KPIs in real-time, enabling quick decision-making based on current data rather than outdated information.

Real-time tracking can be achieved through automated inventory management systems that update data instantaneously. This capability allows you to adjust inventory levels and reorder products as needed to maintain optimal stock levels.

In addition to maintaining optimal stock levels, real-time tracking helps identify trends and patterns in customer behavior. By analyzing real-time data, you can determine which products are performing well and which are not, aiding in informed stocking decisions.

Real-time tracking also helps promptly identify potential issues such as stockouts or overstocking. Continuous monitoring of inventory levels allows you to take proactive measures to prevent these issues.

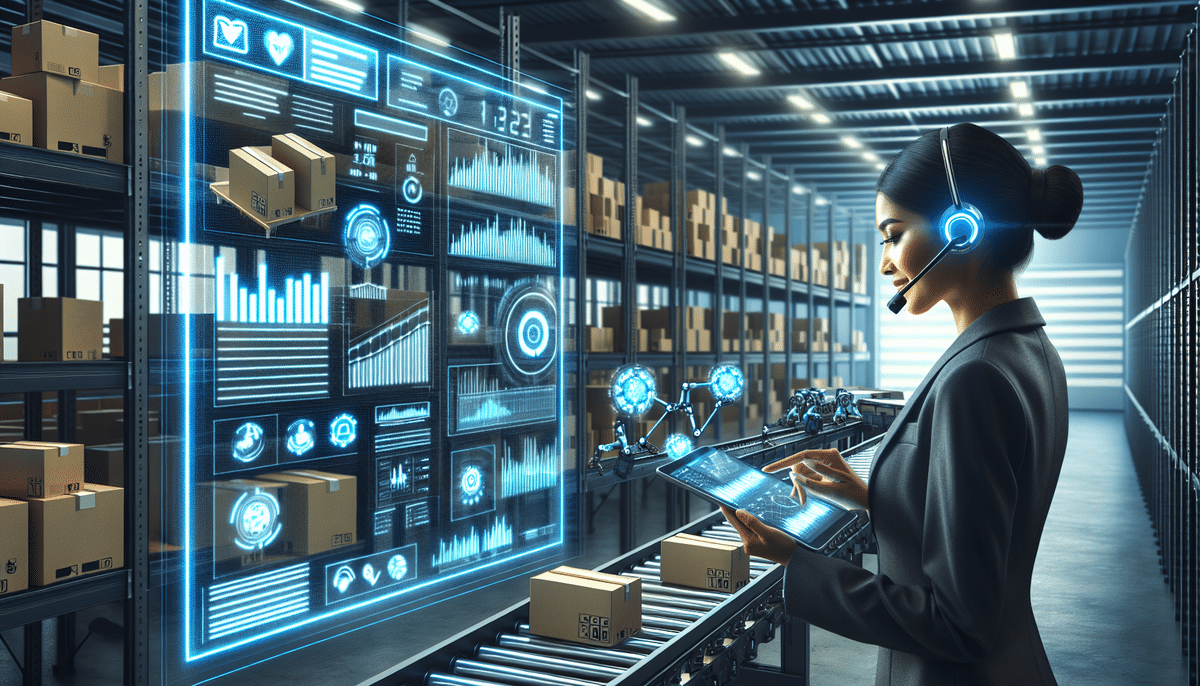

Using Data Analytics to Monitor Inventory Performance

Data analytics provides valuable insights into inventory performance. By analyzing data on sales, inventory levels, lead times, and other KPIs, you can identify patterns and trends that indicate potential problems or opportunities for improvement.

Leveraging data analytics helps pinpoint specific areas where inventory management processes can be enhanced. For example, analyzing sales data can reveal which products are bestsellers and which are underperforming, allowing you to adjust inventory levels accordingly.

Another benefit of data analytics is supply chain optimization. By analyzing lead times and delivery performance, you can identify areas to improve relationships with suppliers and reduce the risk of stockouts or overstocking. Additionally, data analytics enhances demand forecasting accuracy, enabling better decisions regarding inventory ordering and management.

Setting Realistic Goals for Your Inventory KPIs

Setting realistic goals for your inventory KPIs requires a clear understanding of your business objectives. This involves considering factors such as your target market, competition, and growth plans.

Once business objectives are established, set KPI goals that align with these objectives. Goals should be challenging yet achievable and must be measurable effectively.

Analyzing historical data is crucial to ensure KPI goals are realistic. By examining past performance, you can identify areas for improvement and set specific, measurable, and attainable goals for your inventory KPIs.

Budget considerations are also essential when setting KPI goals. Ensure that your goals are financially feasible and that you have the necessary resources to achieve them, which may involve adjusting inventory management processes or investing in new technology.

The Impact of Accurate Forecasting on Inventory KPIs

Accurate forecasting is critical for effective inventory management. It involves estimating future demand based on past sales data, market trends, and other factors. Accurate forecasting enables maintaining optimal inventory levels and avoiding stockouts or excess inventory.

To improve forecasting accuracy, regularly review trends and adjust forecasts accordingly. This may involve adjusting inventory levels, changing ordering processes, or implementing new technology to enhance data accuracy.

External factors such as weather, economic conditions, and political events can significantly impact demand and should be considered in forecasting models.

Accurate forecasting positively affects other KPIs, such as customer satisfaction and profitability. By having the right products in stock at the right time, businesses can enhance customer satisfaction and increase sales, leading to higher profits.

Best Practices for Continuously Improving Your Inventory KPIs

Inventory management is an ongoing process that requires continuous improvement. To achieve optimal results, regularly review your inventory management processes and identify areas for enhancement.

Best practices for continuously improving your inventory KPIs include:

- Benchmarking: Compare your KPIs against industry standards to identify gaps and opportunities for improvement.

- Data Review: Regularly analyze KPI data to track progress and identify trends.

- Technology Adoption: Implement new technologies to enhance efficiency and accuracy in inventory management.

- Staff Training: Ensure your team is well-trained in inventory management best practices and the use of relevant tools and technologies.

Common Challenges in Monitoring and Improving Inventory KPIs

Monitoring and improving inventory KPIs can present several challenges, including:

- Data Accuracy Issues: Inaccurate data can lead to misleading KPI results. Establishing robust data collection and verification processes is essential.

- Limited Supply Chain Visibility: Lack of visibility into supply chain processes can hinder effective inventory management. Collaborate with suppliers and logistics providers to enhance transparency.

- Competing Priorities: Balancing inventory management with other business priorities can be challenging. Prioritize inventory management as a key area for improvement to ensure focus and resources.

To overcome these challenges, establish processes that ensure data accuracy, improve supply chain visibility through collaboration, and prioritize inventory management within your organizational goals.

Case Studies: Examples of Companies with Successful Inventory Management Strategies

Reviewing real-world examples of companies that have successfully implemented inventory management strategies can provide valuable insights. These case studies highlight specific tactics and strategies that have proven effective in optimizing inventory management.

- Walmart: Utilizes advanced real-time tracking and data analytics to manage a vast inventory efficiently, ensuring products are available when and where needed.

- Amazon: Implements sophisticated warehouse management systems and AI-driven forecasting to maintain optimal inventory levels and reduce delivery times.

- Zara: Employs a fast-response inventory system that allows quick adjustments to inventory based on real-time sales data and fashion trends.

These companies leverage technology, data analytics, and innovative strategies to maintain high levels of inventory accuracy and customer satisfaction.

Conclusion

Effective inventory management is critical to the success of any business dealing with physical products. By monitoring the right KPIs, you can gain valuable insights into your inventory management processes and make data-driven decisions that improve efficiency, reduce costs, and increase profitability. Implementing best practices, overcoming common challenges, and learning from successful companies can help you optimize your inventory management strategy and achieve sustained business growth.