The Importance of Accurate Inventory Management

Accurate inventory management is essential to the success of any business. It enables informed decisions about purchasing, pricing, and promotions, ensuring that you maintain the right amount of inventory to meet customer demand and avoid stockouts.

Why Accurate Inventory Management Matters

Effective inventory management helps businesses balance the costs of holding inventory against the benefits of meeting customer demand. According to a Forbes article, companies with high inventory accuracy experience up to a 30% increase in operational efficiency.

Impact of Inaccurate Inventory Management

Inaccurate inventory management can lead to overstocking, tying up capital and increasing storage costs, or stockouts, resulting in lost sales and dissatisfied customers. Both scenarios can significantly impact a company's profitability and reputation.

Key Metrics for Measuring Inventory Accuracy

Measuring inventory accuracy is crucial for identifying areas of improvement. Key metrics include:

- Inventory Accuracy Percentage: Measures the percentage of inventory items accurately recorded in your system versus the actual physical count.

- Inventory Turnover Ratio: Assesses how efficiently inventory is being used by comparing the cost of goods sold with average inventory levels.

- Shrinkage Rate: Calculates the percentage of inventory lost due to theft, damage, or administrative errors.

Regularly monitoring these metrics allows businesses to identify trends and adjust their inventory management practices accordingly.

Common Causes of Inventory Inaccuracy and Solutions

Several factors contribute to inventory inaccuracies:

- Manual Data Entry Errors: Mistakes during data entry can lead to incorrect inventory records. Implementing automated systems like barcode scanners can significantly reduce these errors.

- Shrinkage: Losses due to theft, damage, or misplacement. Enhancing security measures and conducting regular audits can mitigate shrinkage.

- Order Fulfillment Errors: Mistakes in picking, packing, or shipping orders can cause discrepancies in inventory levels. Adopting quality control processes ensures accuracy in order fulfillment.

- Poor Inventory Management Practices: Lack of organization and ineffective tracking systems can lead to inaccuracies. Utilizing advanced inventory management software can improve tracking and organization.

- Lack of Communication Between Departments: Miscommunication between sales, warehouse, and accounting can result in inconsistent inventory data. Establishing regular inter-departmental meetings enhances communication and data accuracy.

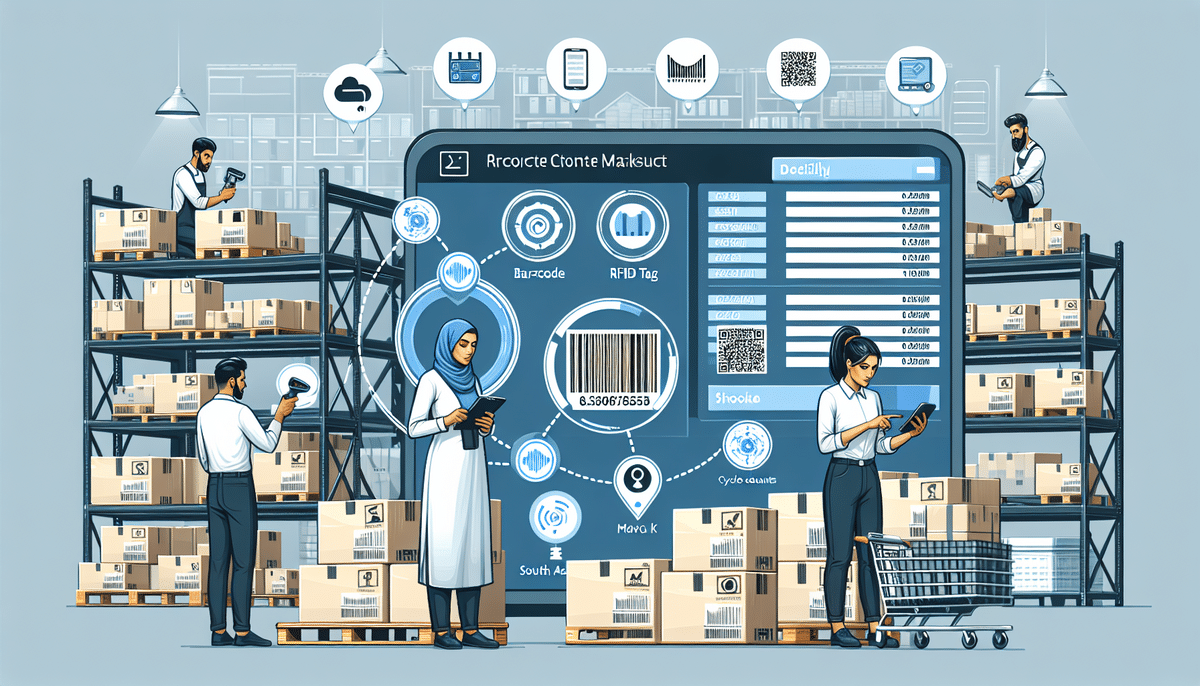

Leveraging Technology to Enhance Inventory Management

Integrating technology into inventory management processes can vastly improve accuracy and efficiency. Key technologies include:

- Inventory Management Software: Automates tracking of inventory levels, orders, sales, and deliveries, providing real-time data and analytics.

- Barcode Scanners: Streamline the data entry process by allowing quick and accurate scanning of inventory items.

- RFID Technology: Utilizes radio frequency identification to track inventory in real-time, reducing manual errors and enhancing data accuracy.

- Automating Replenishment: Automatically reorders stock when inventory levels fall below predetermined thresholds, ensuring timely restocking.

- Real-Time Data Utilization: Provides immediate insights into inventory levels, enabling prompt decision-making and responsiveness to market changes.

Implementing these technologies not only enhances accuracy but also optimizes inventory levels, reduces costs, and improves overall operational efficiency.

Best Practices for Maintaining Inventory Accuracy

Cycle Counting and Physical Inventory Counts

Regular cycle counting and physical inventory counts are vital for maintaining accurate inventory records. Best practices include:

- Regular Scheduling: Conduct counts on a consistent schedule to keep records up to date.

- Random Sampling: Use random sampling methods to ensure all inventory items are regularly verified.

- Double-Checking: Implement a verification process where a second person reviews counts to minimize errors.

Utilizing barcode scanners or RFID technology during counts can further enhance accuracy and efficiency.

Optimizing Warehouse Layout

An organized warehouse layout contributes to inventory accuracy by reducing the likelihood of miscounts and misplaced items. Strategies include:

- Grouping Similar Items: Store similar items together to streamline counting and retrieval processes.

- Labeling and Signage: Use clear labels and signs to indicate storage locations, ensuring items are stored correctly.

- Standardized Processes: Develop and implement standardized procedures for inventory storage and retrieval to maintain consistency.

Staff Training on Inventory Management

Properly trained staff are crucial for accurate inventory management. Training should cover:

- Data Entry: Educate staff on accurate data entry techniques to minimize manual errors.

- Technology Usage: Train staff on the effective use of inventory management software, barcode scanners, and RFID systems.

- Standardized Procedures: Ensure that all employees understand and follow standardized inventory management processes.

- Proper Handling and Storage: Teach staff proper techniques for handling and storing inventory to prevent damage and loss.

Strategies to Prevent Overstocking and Stockouts

Balancing inventory levels is key to preventing overstocking and stockouts. Effective strategies include:

- Optimizing Inventory Levels: Utilize inventory management software to analyze sales data and forecast demand, ensuring optimal inventory levels.

- Implementing Safety Stock: Maintain a buffer stock to accommodate unexpected demand spikes or supply delays.

- Collaborating with Suppliers: Work closely with suppliers to reduce lead times and ensure timely order fulfillment.

- Managing Seasonal Demand Fluctuations: Use historical sales data and forecasting tools to anticipate and plan for seasonal demand changes.

Additionally, adopting a just-in-time (JIT) inventory system can minimize storage costs and reduce the risk of overstocking by ordering inventory only as needed.

Continuous Improvement and Learning from Case Studies

Implementing a Continuous Improvement Program

Inventory management is an ongoing process. Establishing a continuous improvement program involves regularly reviewing inventory metrics, assessing management processes, and incorporating feedback from staff to identify and implement improvements.

Case Studies: Successful Companies

Several companies have successfully enhanced their inventory accuracy through strategic initiatives:

- Target: Implemented RFID technology to improve inventory accuracy and reduce shrinkage, resulting in a 20% decrease in stockouts and a 50% reduction in shrinkage.

- Zara: Utilizes advanced inventory management software to optimize inventory levels and reduce lead times, achieving an industry-leading inventory turnover rate of 2.1.

- Amazon: Employs data analytics and demand forecasting tools to maintain a high inventory turnover rate of 9.5, enabling efficient order fulfillment and minimal stockouts.

Conclusion: Achieving Maximum Efficiency in Your Inventory Management Strategy

Developing an efficient inventory management strategy is critical for business success. By implementing the strategies discussed—such as leveraging technology, adhering to best practices, and continuously improving processes—you can enhance inventory accuracy, reduce costs, and optimize your operations.

Regularly monitor key inventory metrics, utilize advanced tools and technologies, and foster a culture of continuous improvement to sustain and enhance your inventory management efficiency.