Introduction to Digital Twins

Digital twins have revolutionized various industries in recent years, serving as virtual replicas of physical assets, systems, and processes. According to a McKinsey report, the digital twin market is projected to reach $125 billion by 2025, growing at a compound annual growth rate (CAGR) of 37%. These virtual models enable companies to monitor, analyze, and optimize the performance of real-world objects within a simulated environment. In this comprehensive guide, we will explore the origins, concepts, advantages, challenges, and trends of digital twins, along with real-life examples of digital twin implementation and best practices for adoption. By the end of this article, you'll have a solid understanding of digital twins and how they can transform your business.

The Origins and Evolution of Digital Twins

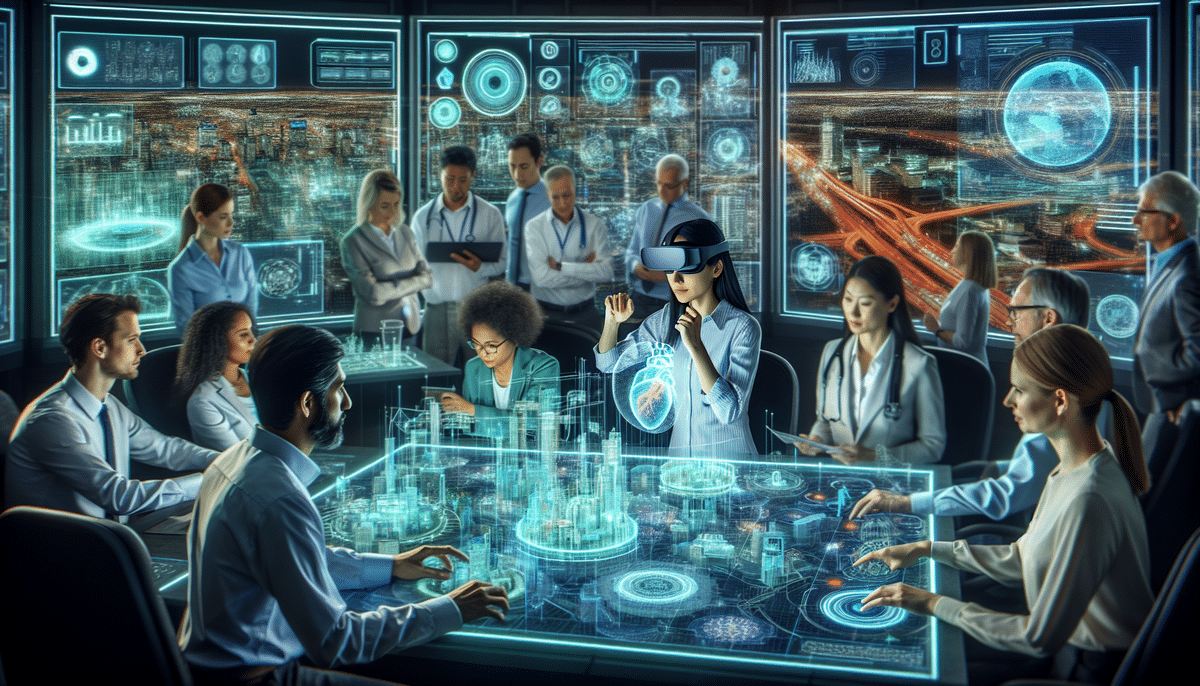

The concept of digital twins originated from NASA's Apollo program in the 1960s, where engineers created models to simulate the behavior of rockets and spacecraft. This pioneering effort laid the foundation for what would become a transformative technology across various sectors. It wasn't until the 2000s that digital twins gained mainstream attention, particularly within the manufacturing industry, where they were leveraged to optimize production processes and minimize downtime. The integration of Internet of Things (IoT) technologies in the 2010s significantly advanced the capabilities of digital twins, enabling real-time data collection, analysis, and visualization. Today, digital twins are employed in diverse industries, including healthcare, transportation, and smart cities, driving innovation and efficiency.

Key Concepts and Advantages of Digital Twins

Understanding the Key Concepts

A digital twin is a dynamic digital representation of a physical asset, system, or process. It integrates data from multiple sources such as sensors, cameras, and machine logs into a unified platform, offering a comprehensive view of the real-world counterpart. By analyzing this data, organizations can identify patterns, optimize performance, and predict potential failures before they occur. Additionally, digital twins facilitate "what-if" scenarios, allowing businesses to test new products or processes in a virtual setting before actual implementation.

Advantages of Using Digital Twins in Industry

- Improved Asset Performance: Real-time monitoring helps identify potential issues before they escalate, ensuring optimal performance.

- Increased Efficiency: Optimizes asset usage and reduces energy consumption, leading to significant cost savings.

- Reduced Maintenance Costs: Predictive maintenance minimizes unexpected downtime and costly repairs.

- Enhanced Safety: Simulates hazardous scenarios to test and implement risk mitigation strategies effectively.

According to a study by Gartner, the adoption of digital twins can reduce maintenance costs by up to 30% and increase operational efficiency by 25%. These benefits are particularly significant in industries where equipment reliability and operational efficiency are critical.

Applications of Digital Twins Across Industries

Manufacturing and Production

In the manufacturing sector, digital twins are instrumental in optimizing production processes, reducing downtime, and enhancing product quality. By creating digital replicas of each stage of the manufacturing process, companies can:

- Simulate different scenarios to identify potential bottlenecks.

- Optimize production in real-time based on dynamic data.

- Monitor factory equipment to predict maintenance needs, thereby reducing downtime and maintenance costs.

For instance, Siemens uses digital twins to simulate and optimize manufacturing processes, resulting in a 20% increase in production efficiency (Siemens Digital Twin Solutions).

Healthcare

In healthcare, digital twins are transforming personalized medicine by creating patient-specific models. These models can simulate the effects of different treatments, predict outcomes, and optimize surgical procedures. This technology enables doctors to make more informed decisions, ultimately improving patient care and outcomes.

- Patient-Specific Models: Simulate patient conditions to test various treatment options.

- Optimizing Surgical Procedures: Plan and rehearse surgeries using virtual models to enhance precision and outcomes.

- Disease Spread Modeling: Predict and manage potential disease outbreaks through accurate simulations.

According to Health IT, digital twins in healthcare can reduce surgical complications by up to 40% and improve treatment efficacy significantly.

Transportation and Infrastructure

Digital twins are extensively used in the transportation industry to optimize vehicle performance and infrastructure maintenance. For example, digital twins of bridges and tunnels can monitor structural health and predict maintenance needs, while digital twins of vehicles can enhance fuel efficiency and reduce emissions.

- Structural Health Monitoring: Real-time monitoring of infrastructure to predict and prevent failures.

- Vehicle Optimization: Enhance fuel efficiency and reduce emissions through continuous performance analysis.

Companies like General Electric (GE) utilize digital twins to monitor and diagnose wind turbines, predicting potential issues before they occur and minimizing downtime (GE Digital Twin Solutions).

Future Trends and Key Players

Emerging Trends

- Smart Cities: Increasing use of digital twins in urban planning to optimize transportation, energy usage, and public safety.

- Autonomous Vehicles: Digital twins will play a crucial role in developing and testing autonomous vehicles, enabling virtual performance optimization before road deployment.

- Integration with AI and Machine Learning: Enhanced data analysis and predictive capabilities through the integration of artificial intelligence and machine learning technologies.

- Expansion Across Industries: Wider adoption in sectors such as retail, energy, and entertainment, fostering innovation and efficiency.

These trends indicate that digital twins will continue to evolve, driving further innovation and efficiency across various fields.

Key Players in the Digital Twin Industry

- Siemens: Offers comprehensive digital twin solutions for manufacturing, energy, and infrastructure (Siemens Digital Twin).

- IBM: Provides digital twin services integrated with AI and IoT technologies (IBM Digital Twin).

- Microsoft: Features Azure Digital Twins, a platform for creating and managing digital twin environments (Azure Digital Twins).

- General Electric (GE): Utilizes digital twins to monitor and diagnose wind turbines and other industrial equipment (GE Digital Twin).

- ANSYS: Specializes in simulation-based digital twin solutions for product design and optimization (ANSYS Digital Twin).

- PTC: Provides digital twin technology through its ThingWorx platform, focusing on IoT integration (PTC ThingWorx).

These industry leaders are at the forefront of digital twin innovation, offering robust solutions that cater to diverse business needs.

Implementation Strategies and Best Practices

Challenges in Adopting Digital Twins

- Data Quality: Digital twins rely on accurate and timely data. Poor data quality can significantly hinder their effectiveness.

- Significant Investment: Implementing digital twins requires substantial investment in technology and infrastructure, which can be a barrier for some companies.

- Integration with Existing Systems: Ensuring seamless integration with current technologies and processes can be complex and resource-intensive.

- Skilled Personnel: A lack of skilled professionals to develop and manage digital twins can impede successful adoption.

Best Practices for Successful Adoption

- Focus on Data Quality: Ensure that data is accurate, timely, and comprehensive to maximize the effectiveness of digital twins.

- Define Clear Goals and Use Cases: Identify specific areas where digital twins can provide the most value to your business.

- Create a Scalable and Secure Platform: Develop a platform that can grow with your company's needs while ensuring the protection of sensitive data.

- Invest in Talent and Training: Hire skilled professionals and provide ongoing training to effectively utilize digital twin technology.

- Integrate with Existing Technologies: Seamlessly incorporate digital twins into your current systems and processes to ensure smooth operations.

By addressing these challenges and adhering to best practices, companies can effectively implement digital twins and unlock their full potential.

Case Studies: Real-Life Examples of Successful Digital Twin Implementation

- Rolls-Royce: Utilizes digital twins to optimize aircraft engine performance, predict maintenance needs, and enhance reliability. This approach has led to a reduction in unplanned maintenance by 20% (Rolls-Royce Digital Twin).

- China Railways: Employs digital twins to simulate and optimize train schedules, improving efficiency and reducing delays by 15% (China Railways Digital Twin).

- General Electric (GE): Uses digital twins to monitor and diagnose wind turbines, predicting potential issues before they occur and minimizing downtime by 25% (GE Wind Digital Twin).

These case studies demonstrate the tangible benefits of digital twins, including improved performance, reduced costs, and enhanced operational efficiency. They also provide valuable insights into best practices for effective digital twin implementation.

Conclusion

Digital twins represent a transformative technology with the potential to revolutionize various industries. By creating virtual replicas of physical assets, systems, and processes, companies can optimize performance, reduce downtime and maintenance costs, and enhance safety. The integration of digital twins with emerging technologies like AI and IoT further expands their capabilities, driving innovation and efficiency. While challenges such as data quality and significant investment exist, adopting best practices can help organizations overcome these hurdles and fully leverage the benefits of digital twins. As the technology continues to evolve, digital twins are poised to play a critical role in shaping the future of business operations and improving the world around us.