The Benefits of Inventory Tracking for Businesses

Running a successful business involves juggling countless tasks, and inventory management is undoubtedly one of them. From balancing stock levels to ordering just enough supplies to meet customer demand, staying on top of inventory can seem like a daunting task. However, the benefits of inventory tracking for businesses warrant the investment of time and resources. Not only can inventory tracking save businesses money, but it can also lead to more efficient operations and ultimately increase profitability. In this article, we will explore the importance of inventory tracking, the role of technology in inventory tracking, and the benefits that businesses can reap by implementing an inventory tracking system.

The Importance of Inventory Tracking

Inventory tracking is an essential part of any business that deals with physical goods. Tracking inventory levels can help businesses determine when stock is running low and when to reorder products. It is easy to overlook the importance of inventory tracking when things are going well, but it only takes one stockout or overstocking incident to realize the value of keeping a close eye on your inventory.

Moreover, inventory tracking can also help businesses identify which products are selling well and which ones are not. By analyzing sales data and inventory levels, businesses can make informed decisions about which products to promote or discontinue, leading to increased profitability and a more efficient use of resources. Additionally, inventory tracking can help businesses detect and prevent theft or loss of inventory, which can be a significant cost for businesses. Overall, implementing a robust inventory tracking system can have a positive impact on a business's bottom line and overall success.

The Role of Technology in Inventory Tracking

Gone are the days of manual inventory tracking with pen and paper. Advancements in technology have brought about inventory management systems that make tracking inventory levels much more efficient and accurate. Barcode scanners, radio-frequency identification (RFID) tags, and inventory management software are just some examples of technology that businesses can use to streamline their inventory tracking processes.

One of the biggest advantages of using technology for inventory tracking is the ability to track inventory in real-time. With manual tracking methods, it can take hours or even days to update inventory levels. However, with the use of technology, businesses can track inventory levels in real-time, allowing them to make informed decisions about restocking and reducing the risk of stockouts. Additionally, technology can help businesses identify trends in inventory levels, allowing them to adjust their ordering and stocking processes to better meet customer demand.

Emerging Technologies

Emerging technologies such as artificial intelligence (AI) and machine learning are further enhancing inventory tracking systems. These technologies can predict demand with greater accuracy, optimize stock levels, and even automate the reordering process.

Types of Inventory Tracking Systems

There are many different types of inventory tracking systems available, each with its own unique features and benefits. Some common types of inventory tracking systems include:

- Perpetual inventory systems: These are real-time tracking systems that continuously monitor inventory levels and update them as soon as a transaction occurs. This type of system provides accurate and up-to-date information on inventory levels, which can help businesses make informed decisions about purchasing and stocking products. However, perpetual inventory systems can be more complex and expensive to implement than other types of inventory tracking systems.

- Periodic inventory systems: These systems update inventory levels at specific intervals, rather than continuously. While simpler and less costly to implement, they may not provide the same level of accuracy as perpetual systems.

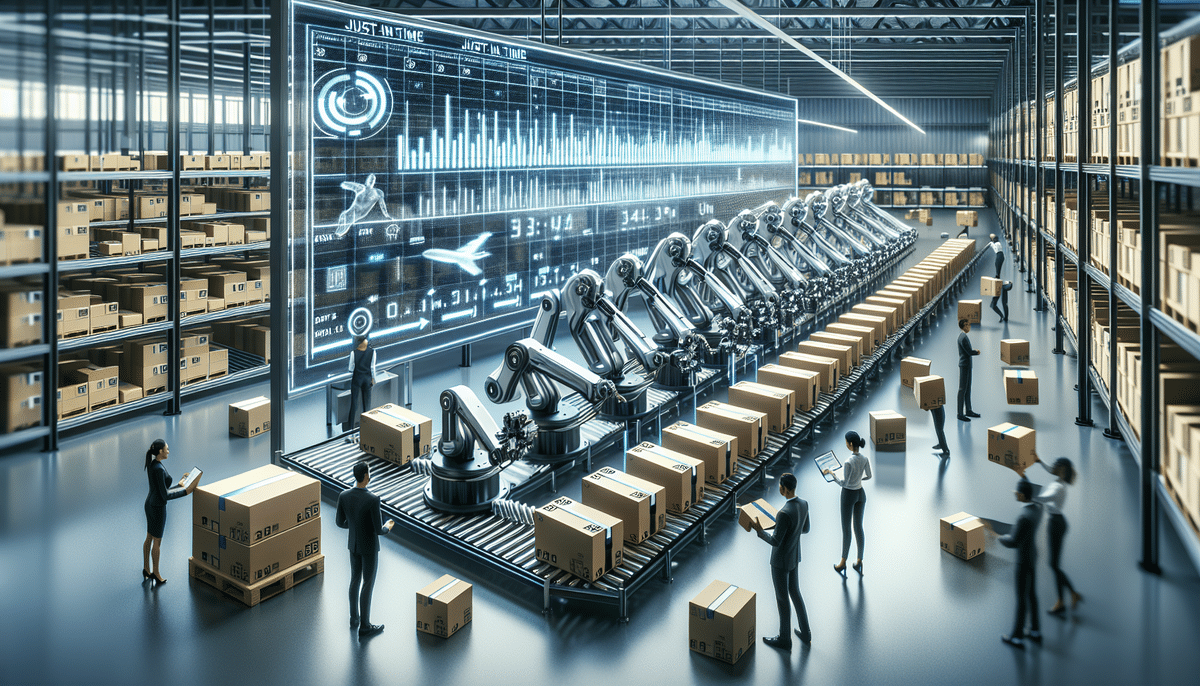

- Just-in-time (JIT) inventory systems: JIT systems aim to minimize inventory levels by receiving goods only as they are needed in the production process. This reduces holding costs but requires precise demand forecasting and reliable suppliers.

Choosing the right system for your business requires careful consideration of your specific needs and operational dynamics.

Choosing the Right Inventory Tracking System for Your Business

Selecting the appropriate inventory tracking system is crucial for your business's success. Key factors to consider include:

- Type and volume of products you sell

- Business size and budget

- Specific inventory needs

Assess these factors to ensure that you invest in a system that aligns with your business's unique requirements.

An important consideration is the compatibility of the inventory tracking system with your existing software and hardware. If you already have a point-of-sale system or accounting software in place, ensure that your inventory tracking system can integrate seamlessly with these platforms. This integration will save time and reduce the likelihood of manual data transfers, which can lead to errors.

Additionally, consider the level of support and training offered by the inventory tracking system provider. Comprehensive training and ongoing support are essential to ensure that your team can effectively use the system, minimizing costly mistakes and maintaining accurate inventory data.

Evaluating System Features

- Real-time tracking capabilities

- Scalability to grow with your business

- User-friendly interface

- Comprehensive reporting tools

The Benefits of Real-Time Inventory Tracking

Real-time inventory tracking is a powerful tool that allows businesses to make informed decisions regarding their inventory levels. With real-time tracking, businesses can access up-to-the-minute data on inventory levels, enabling them to swiftly identify and respond to stockouts or overstocking incidents. This agility allows for more accurate demand forecasting, leading to better purchasing and inventory management decisions.

In addition to these benefits, real-time inventory tracking can also help businesses reduce costs associated with inventory management. By understanding current inventory levels, businesses can avoid overstocking, thereby reducing the need for costly storage space. Furthermore, real-time tracking helps identify slow-moving inventory, allowing businesses to make strategic decisions on how to manage and sell these items effectively. Overall, real-time inventory tracking enhances inventory management processes and contributes to significant cost savings.

How Inventory Tracking Improves Supply Chain Management

Effective supply chain management requires the seamless coordination of various processes, including procurement, manufacturing, and shipping. Inventory tracking plays a vital role in ensuring that each of these processes operates smoothly. By maintaining accurate and up-to-date inventory data, businesses can better plan and manage their supply chain, minimizing delays and enhancing overall efficiency.

One of the key benefits of inventory tracking is the ability to identify trends and patterns in inventory levels. This insight allows businesses to optimize inventory levels, reducing the risk of stockouts or overstocking. Maintaining optimal inventory levels helps reduce carrying costs and improve cash flow.

Additionally, inventory tracking enables businesses to identify and address supply chain bottlenecks. By monitoring inventory levels at each stage of the supply chain, businesses can pinpoint areas where delays occur and take corrective action. This proactive approach enhances supply chain efficiency and shortens lead times, providing a competitive edge in today’s fast-paced business environment.

Reducing Stock-Outs and Overstocking with Inventory Tracking

Stockouts and overstocking can significantly impact a business's profitability. Stockouts can lead to lost sales and dissatisfied customers, while overstocking ties up valuable capital that could be invested elsewhere. Inventory tracking mitigates these issues by enabling accurate demand forecasting and adjusting inventory levels accordingly, resulting in substantial cost savings and more efficient operations.

Furthermore, inventory tracking helps businesses identify slow-moving or obsolete inventory. By analyzing inventory levels and sales data, businesses can determine which items are not performing as expected and take steps to reduce their stock or discontinue them altogether. This strategy frees up valuable warehouse space and prevents the accumulation of unsellable inventory.

Additionally, accurate inventory data improves customer service. Businesses can provide real-time information on product availability and delivery times, enhancing customer trust and satisfaction.

Cost Savings Achieved Through Inventory Tracking

Investing in an inventory tracking system may seem like a significant expense initially, but it can lead to considerable cost savings over time. By preventing stockouts and overstocking, businesses can reduce waste and lower holding costs. Inventory tracking also aids in identifying obsolete or slow-moving inventory, allowing businesses to efficiently clear out these items and free up space and capital for more profitable products.

According to a Investopedia report, effective inventory management can reduce unnecessary expenses by up to 20%, highlighting the financial benefits of implementing robust inventory tracking systems.

The Impact of Accurate Inventory Data on Decision-Making

Accurate inventory data is crucial for making informed business decisions. With precise data, businesses can determine optimal purchasing quantities, identify best-selling products, and understand sales trends. This information allows businesses to optimize inventory levels, improve profitability, and scale their operations effectively.

Moreover, accurate inventory data supports strategic planning and forecasting. Businesses can anticipate market demand, adjust marketing strategies, and allocate resources more efficiently, ensuring long-term sustainability and growth.

Integrating Inventory Tracking with Other Business Processes

For maximum efficiency, inventory tracking should be integrated with other business processes. For instance, integrating inventory data with marketing and sales strategies enables businesses to identify popular products and tailor promotions accordingly. Furthermore, integrating inventory tracking with accounting software streamlines the purchasing process and ensures accurate financial records.

Such integrations facilitate seamless data flow across departments, reducing redundancies and enhancing overall operational efficiency. Additionally, they provide a comprehensive view of business performance, aiding in holistic decision-making.

Overcoming Common Challenges in Inventory Tracking

Implementing an inventory tracking system can present several challenges, including data entry errors, system integration issues, and resistance to change among staff. To address these challenges, businesses should invest in comprehensive employee training to ensure proper system usage and minimize errors. Additionally, selecting a system that offers robust integration capabilities can alleviate many technical hurdles.

Establishing checks and balances, such as regular audits and data verification processes, can further enhance the accuracy and reliability of inventory data. Encouraging a culture of continuous improvement and openness to technological advancements can also help overcome resistance and facilitate successful system adoption.

Best Practices for Successful Inventory Tracking Implementation

Successful implementation and maintenance of an inventory tracking system require a strategic approach. Businesses should:

- Select a system that aligns with their specific needs and scales with growth

- Ensure seamless integration with existing software and hardware

- Provide comprehensive training and ongoing support to employees

- Conduct regular audits to maintain data accuracy

- Continuously assess and refine inventory management processes

Adhering to these best practices ensures that the inventory tracking system delivers maximum value and supports the business’s operational goals.

Case Studies: Successful Implementation of Inventory Tracking

Many businesses have experienced significant benefits from implementing inventory tracking systems. For example, Zara, a leading fashion retailer, utilizes RFID technology to monitor its inventory levels in real-time. This approach allows Zara to respond swiftly to customer demand, optimize stock levels, and maintain an efficient supply chain. As a result, Zara has enhanced its operational efficiency and increased sales.

Another example is Walmart, which employs advanced inventory management systems to maintain optimal stock levels across its global network of stores. By leveraging data analytics and real-time tracking, Walmart minimizes stockouts and overstocking, ensuring product availability and customer satisfaction.

For more insights into successful inventory tracking implementations, refer to industry reports from sources like Supply Chain Digital and Investopedia.

Future Trends in Inventory Tracking Technology

The future of inventory tracking technology is promising, with continuous advancements set to revolutionize inventory management. Emerging trends include the increased use of artificial intelligence (AI) and machine learning to enhance demand forecasting and automate inventory replenishment. AI-driven systems can analyze vast amounts of data to predict market trends and consumer behavior, enabling businesses to make proactive inventory decisions.

Another trend is the development of smart tagging systems that can track inventory in transit using Internet of Things (IoT) devices. These smart tags provide real-time visibility into the location and status of inventory, reducing the risk of loss and improving supply chain transparency.

Additionally, blockchain technology is being explored for its potential to provide secure and transparent inventory records, enhancing trust and accuracy in inventory tracking systems.

Conclusion

Inventory tracking may seem like a tedious and time-consuming task, but the benefits it provides are undeniable. From reducing costs to improving supply chain management and increasing profitability, inventory tracking is essential for businesses of all sizes and industries. By choosing the right inventory tracking system and implementing best practices for maintenance and use, businesses can fully leverage the advantages of inventory tracking to drive success and growth.