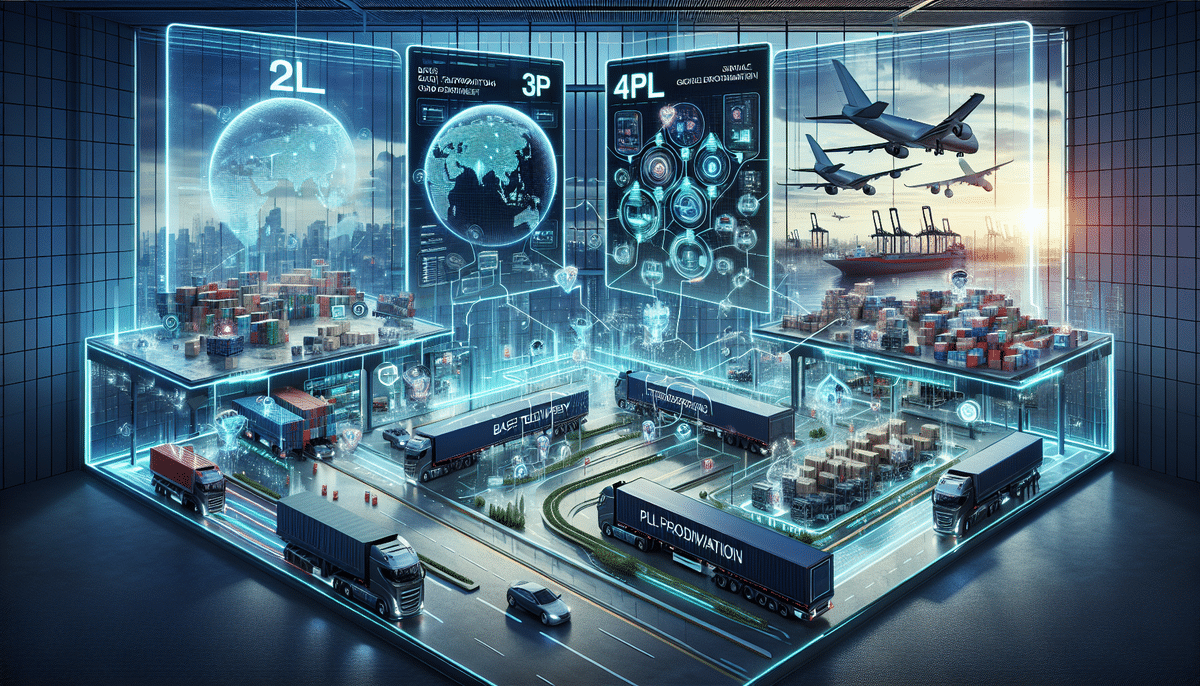

Introduction to Logistics Outsourcing: 2PL, 3PL, and 4PL

In today's global economy, logistics and supply chain management are critical components for the success of any business. Efficiently managing the flow of goods and services from the point of origin to the point of consumption is essential in maintaining competitiveness. Over the years, businesses have adopted various logistics outsourcing models, including 2PL (Second-Party Logistics), 3PL (Third-Party Logistics), and 4PL (Fourth-Party Logistics). This article explores these models, their distinctions, and their impact on modern supply chains.

Detailed Analysis of 2PL, 3PL, and 4PL Models

Basics of Logistics and Supply Chain Management

Logistics involves planning, implementing, and controlling the movement and storage of goods from the point of origin to the point of consumption. Supply chain management extends this by coordinating all activities involved in producing and delivering goods and services, including interactions among suppliers, manufacturers, distributors, retailers, and customers.

The Evolution of Logistics: From 1PL to 4PL

The outsourcing of logistics operations has evolved from 1PL (First-Party Logistics), where companies manage logistics in-house, to more complex models like 2PL, 3PL, and 4PL. This evolution is driven by the increasing complexity of global supply chains and the need for specialized expertise. According to a Forbes article, the shift towards higher levels of outsourcing allows businesses to leverage advanced technologies and specialized services to enhance efficiency and scalability.

Second-Party Logistics (2PL)

How 2PL Works

2PL involves outsourcing specific logistics functions such as transportation and warehousing to external service providers. Companies retain control over their logistics operations while delegating particular tasks to specialists.

Advantages of 2PL

- Cost Efficiency: Reduces the need for capital investment in logistics infrastructure.

- Expertise: Leverages the specialized knowledge and networks of logistics providers.

- Focus on Core Activities: Allows businesses to concentrate on their primary operations.

Disadvantages of 2PL

- Limited Scope: Only specific functions are outsourced, potentially leading to integration challenges.

- Dependency: Reliance on external providers can pose risks if the provider faces disruptions.

Third-Party Logistics (3PL)

How 3PL Helps Streamline Operations

3PL providers offer comprehensive logistics services, including transportation, warehousing, inventory management, and technology solutions like Transportation Management Systems (TMS) and Warehouse Management Systems (WMS). According to a Supply Chain Digital report, the global 3PL market is expected to reach $1.3 trillion by 2027, highlighting its growing importance.

Benefits of 3PL

- Scalability: Easily adjusts services based on business needs.

- Technology Integration: Access to advanced logistics technologies.

- Risk Management: Shares and mitigates operational risks.

Drawbacks of 3PL

- Loss of Control: Limited oversight over logistics operations.

- Communication Challenges: Potential for misalignment between company and provider.

Fourth-Party Logistics (4PL)

Advantages and Challenges of 4PL

4PL represents a higher level of outsourcing, where a single provider manages the entire supply chain on behalf of the client. This includes the coordination of multiple 3PL providers and the integration of all logistics functions. A Harvard Business Review article emphasizes that 4PL can offer enhanced visibility, strategic planning, and streamlined operations through comprehensive oversight.

- Advantages:

- End-to-End Supply Chain Management

- Increased Efficiency and Agility

- Advanced Analytics and Technology Integration

- Challenges:

- Higher Costs Compared to 3PL

- Reduced Control Over Logistics Operations

- Potential for Vendor Lock-In

Choosing and Implementing the Right Logistics Model

When to Use 2PL, 3PL, or 4PL

The decision to adopt 2PL, 3PL, or 4PL depends on various factors, including the scale of operations, industry requirements, geographic reach, and the complexity of logistics activities. For instance:

- 2PL: Suitable for smaller companies with straightforward logistics needs.

- 3PL: Ideal for medium-sized businesses requiring comprehensive logistics services and scalability.

- 4PL: Best for large enterprises with complex, global supply chains seeking integrated and strategic logistics management.

Selecting the Best Logistics Partner

Choosing the right logistics partner involves evaluating several key factors:

- Expertise and Experience: Assess the provider's industry knowledge and track record.

- Technology Capabilities: Ensure access to advanced logistics technologies and systems.

- Geographic Coverage: Verify the provider's network aligns with your business's geographic needs.

- Cost Structure: Analyze pricing models to ensure cost-effectiveness.

- Service Level Agreements (SLAs): Clearly define expectations and performance metrics.

Additionally, sustainability practices are becoming increasingly important. Partners committed to green logistics can help reduce environmental impacts and enhance corporate social responsibility. A study by the McKinsey & Company highlights that sustainable logistics practices not only benefit the environment but also improve operational efficiency and brand reputation.

Case Studies: Successful Implementations of Logistics Models

Apple Inc.

Apple Inc. utilizes multiple 3PL providers to manage its global supply chain, ensuring the efficient distribution of its products worldwide. By leveraging specialized 3PL services, Apple maintains high standards of quality and sustainability while scaling its operations to meet global demand.

Amazon

Amazon has developed an extensive in-house logistics network while incorporating elements of 3PL and 4PL strategies. This hybrid approach allows Amazon to maintain control over key logistics functions while benefiting from the flexibility and expertise of external providers, enabling rapid and reliable delivery services.

General Motors (GM)

General Motors outsourced its entire logistics operations to a 4PL provider, resulting in significant cost reductions and enhanced visibility across its supply chain. The 4PL provider coordinated multiple 3PL partners, optimizing transportation routes and inventory management through advanced analytics.

Nike

Nike employs a 2PL strategy by outsourcing transportation and warehousing to logistics providers. This approach allows Nike to focus on design and marketing while ensuring efficient supply chain operations and cost management.

Future Trends in Logistics and Supply Chain Management

Technological Advancements

The logistics industry is rapidly evolving with the adoption of technologies such as artificial intelligence (AI), blockchain, autonomous vehicles, and robotics. These technologies enhance efficiency, reduce costs, and improve accuracy in supply chain operations. For example, AI-driven predictive analytics can optimize inventory levels and forecast demand, while blockchain ensures transparency and security in transactions.

Sustainability and Green Logistics

There is a growing emphasis on sustainable logistics practices. Companies are adopting eco-friendly packaging, optimizing transportation routes to minimize fuel consumption, and integrating renewable energy sources into their logistics operations. According to the United Nations Global Compact, sustainable supply chains can lead to reduced environmental impact and enhanced corporate reputation.

Big Data and Analytics

The use of big data analytics is transforming supply chain management. By analyzing vast amounts of data, companies can gain insights into consumer behavior, optimize supply chain processes, and improve decision-making. Data-driven strategies facilitate real-time tracking, demand forecasting, and risk management, contributing to more resilient and responsive supply chains.

Last-Mile Delivery Innovations

Innovations in last-mile delivery are addressing challenges such as urban congestion and increasing customer expectations. The use of drones, electric vehicles, and automated delivery systems are becoming more prevalent, offering faster and more sustainable delivery options. A report by McKinsey & Company suggests that these technologies will play a crucial role in shaping the future of logistics.

Conclusion

Choosing the right logistics outsourcing model—whether 2PL, 3PL, or 4PL—is a strategic decision that can significantly impact a company's efficiency and competitiveness. By understanding the differences between these models and considering factors such as business size, complexity, and strategic goals, companies can make informed decisions to optimize their supply chain operations. Additionally, staying abreast of emerging trends and technological advancements will ensure that businesses remain agile and resilient in an ever-evolving market landscape.