Peak Season Playbook: Strategies from a Rapidly Expanding 3PL

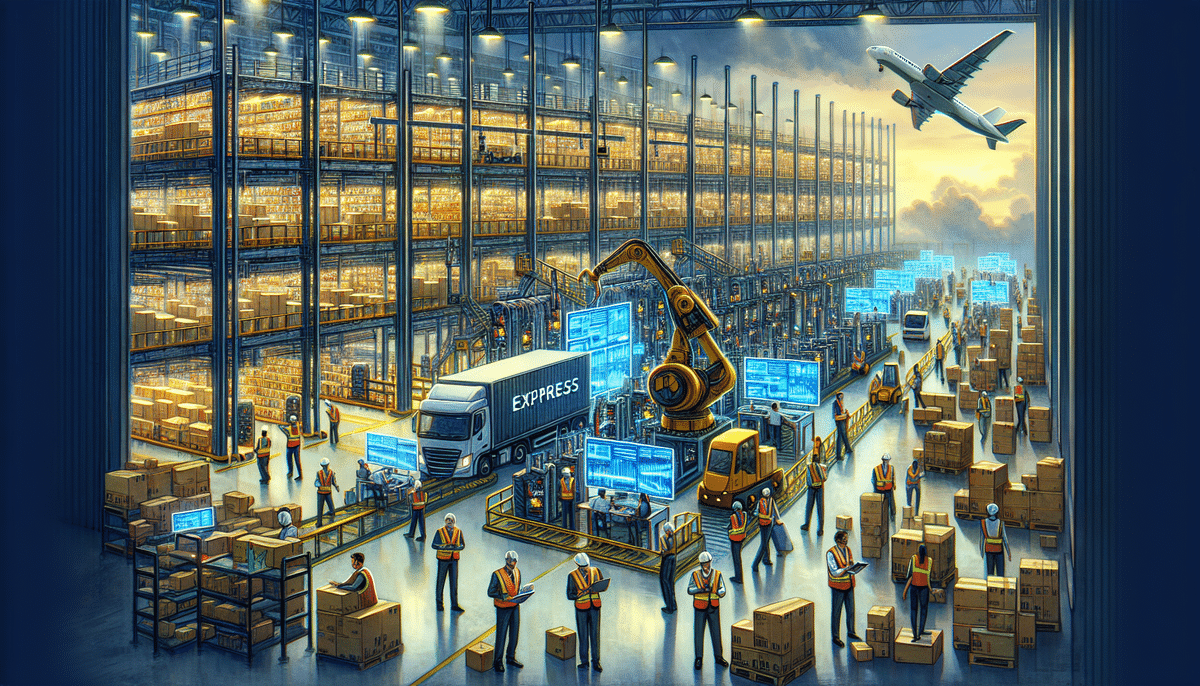

In this article, we explore peak season logistics strategies in collaboration with a rapidly expanding third-party logistics (3PL) provider. The peak season can exert immense pressure on businesses to meet soaring demand and ensure efficient deliveries. This is where a 3PL becomes an invaluable partner. Let’s delve into some actionable insights on navigating peak season logistics with a 3PL.

Introduction to Peak Season Logistics Strategies

The peak season represents the busiest period of the year when businesses witness the highest demand for their products or services. Retailers and manufacturers must ensure that their supply chains are agile, efficient, and capable of meeting customer expectations during this time. An effective peak season logistics strategy should optimize the entire process, from demand forecasting to final delivery.

One of the primary challenges during peak season is managing inventory levels. Businesses must balance having sufficient inventory to meet demand without overstocking and tying up valuable resources. This requires accurate forecasting and real-time inventory tracking, achievable through advanced technology and data analytics. Additionally, businesses may need to consider alternative transportation methods, such as air freight or expedited shipping, to ensure timely deliveries during peak periods.

Understanding the Role of a 3PL in Peak Season Logistics

A 3PL provides value-added logistics services that help businesses manage their supply chains more effectively. With their expertise in logistics, 3PLs can optimize inventory management, streamline order fulfillment, and handle transportation and shipping more efficiently. During the peak season, 3PLs can offer additional services such as overflow warehousing, enhanced inventory management, and expedited order processing to help businesses cope with increased demand.

Key benefits of working with a 3PL during peak season include:

- Scalability: 3PLs can rapidly scale operations to manage increased volume, eliminating the need for businesses to invest in additional resources or infrastructure.

- Real-Time Visibility: 3PLs provide access to real-time inventory levels and order statuses, enabling businesses to make informed operational decisions and ensure timely fulfillment.

- Cost Efficiency: By leveraging the 3PL’s existing infrastructure and expertise, businesses can reduce logistical costs associated with peak season operations.

Key Challenges of Peak Season Logistics and How to Overcome Them

Managing inventory effectively is one of the most significant challenges during peak season. Excess inventory leads to increased storage costs, while insufficient inventory can result in stockouts and lost sales. Accurate demand forecasting and planning provide businesses with insights into expected demand, allowing for more precise inventory management.

Another challenge is handling the surge in orders. A 3PL can support businesses by managing order processing and fulfillment, allowing companies to focus on other operational aspects. According to the Statista Report, online retail sales during the holiday season increased by over 20% in 2023, highlighting the need for efficient order management.

Transportation and shipping demands escalate during peak season, making it essential to have reliable transportation partners and shipping carriers to ensure timely delivery. Partnering with multiple carriers and having contingency plans can mitigate delays or disruptions.

Additionally, peak season logistics can stretch a business's workforce. Hiring and training additional staff can be time-consuming and costly. Outsourcing some operations to a 3PL provides access to experienced personnel, alleviating the burden on the business.

Tips for Effective Inventory Management During Peak Season

Effective inventory management is crucial during peak season to ensure timely deliveries and prevent stockouts. Utilizing technology to monitor inventory levels offers real-time visibility and optimizes stock management. Additionally, leveraging a 3PL’s warehousing and inventory management services enhances storage and handling efficiency.

Forecasting demand by analyzing historical sales data and market trends allows businesses to predict product demand and adjust inventory levels accordingly, preventing overstocking or understocking. According to a report by McKinsey, companies with accurate demand forecasting can reduce inventory costs by up to 25%.

Implementing a just-in-time (JIT) inventory management system helps reduce inventory holding costs and improve cash flow by ordering and receiving inventory only when needed. This approach ensures sufficient inventory to meet customer demand without excessive stock.

Importance of Accurate Forecasting and Planning in Peak Season Logistics

Accurate demand forecasting and planning are foundational to successful peak season logistics. Understanding expected demand helps manage inventory effectively and ensures smooth supply chain operations. Techniques such as historical sales data analysis, trend analysis, and machine learning provide valuable insights into future customer demand.

Beyond forecasting, businesses must consider transportation and distribution strategies. Partnering with reliable carriers and logistics providers, optimizing delivery routes, and increasing warehouse capacity are essential to handle increased demand during peak season.

Prioritizing customer satisfaction is also crucial. Ensuring orders are delivered on time and in good condition may require additional quality control measures, such as product inspections before shipment and using temperature-controlled transportation for perishable goods.

The Role of Technology in Streamlining Peak Season Operations

Peak seasons demand streamlined operations to meet high demand efficiently. Technologies like Warehouse Management Systems (WMS) and Transportation Management Systems (TMS) provide essential insights and efficiencies for a successful peak season. Automating processes reduces costs and minimizes the risk of errors.

Real-time inventory tracking enables businesses to identify low stock levels promptly and take action to replenish inventory before shortages occur. Additionally, technology helps optimize supply chains by identifying efficient transportation routes and reducing the time it takes to move goods between locations.

Data analysis tools empower businesses to make informed decisions by collecting and analyzing data on customer behavior. Identifying sales trends allows businesses to adjust production and marketing strategies accordingly, ensuring they can meet demand and capitalize on opportunities.

Best Practices for Efficient Order Fulfillment During Peak Season

During peak season, efficient order fulfillment is critical. Businesses should accelerate their fulfillment processes by:

- Optimizing order picking procedures through organized shelving and automation

- Automating order processing with integrated software solutions

- Partnering with an experienced 3PL to leverage specialized fulfillment expertise

Collaborating with a 3PL provider enables businesses to utilize advanced fulfillment technologies and streamlined processes, ensuring quick, accurate, and timely delivery of goods to customers.

Strategies for Managing Transportation and Shipping During Peak Season

Transportation and shipping are vital components of logistics operations that require careful optimization during peak season. Strategies include:

- Minimizing shipping costs while ensuring timely deliveries by negotiating bulk rates with carriers

- Utilizing a range of transportation and shipping options provided by 3PLs to offer flexibility

- Balancing speed and cost requirements through strategic carrier partnerships

- Leveraging a 3PL’s extensive network of carriers to ensure reliable transportation services

These strategies help businesses maintain delivery timeframes and manage increased shipping volumes effectively, as supported by industry studies from the Supply Chain Digital.

Maximizing Warehouse Efficiency During Peak Season with Lean Principles

Optimizing warehouse operations is crucial during peak season. Implementing lean principles helps streamline warehouse processes by eliminating waste, reducing errors, and improving overall efficiency. Key practices include:

- Using the right tools and equipment to enhance productivity

- Optimizing storage layouts for quicker access and movement

- Reducing the time it takes to move goods through efficient workflow design

By adopting lean principles, businesses can enhance warehouse productivity and better utilize their assets during peak season operations, as outlined by Lean Enterprise Institute.

Building Strong Relationships with Customers and Suppliers During Peak Season

Building strong relationships with customers is essential for successful logistics operations during peak season. Personalized customer service, quick issue resolution, and transparent communication help ensure customer satisfaction.

Establishing solid relationships with suppliers is equally important to ensure businesses have the necessary resources to meet demand. A 3PL can provide access to a broad network of suppliers, enhancing the efficiency and reliability of supply chains when it matters most.

Case Studies: Successful Peak Season Logistics Strategies Implemented by 3PLs

Various businesses have achieved significant success with their peak season logistics strategies by partnering with a 3PL. For instance, a leading e-commerce fashion retailer collaborated with a 3PL to navigate peak season demands. The 3PL utilized real-time data analytics, automation, and custom logistics solutions to facilitate the rapid delivery of products to customers during the busy season.

Another example includes a major electronics manufacturer that benefited from a 3PL's expertise in forecasting and planning, inventory management, and supply chain optimization. This partnership demonstrated the value of strategic 3PL collaborations during peak periods, resulting in enhanced customer satisfaction and operational efficiency.

Future Trends in Peak Season Logistics and How to Prepare for Them

As consumer expectations and market trends evolve, businesses must prepare for future challenges in peak season logistics. Emerging trends include:

- Increased demand for sustainable shipping practices

- Adoption of advanced technologies like artificial intelligence and machine learning

- Shifting consumer preferences towards faster and more flexible delivery options

These trends are likely to reshape the peak season logistics landscape. To successfully mitigate potential challenges, businesses must remain agile and adaptable. Partnering with a 3PL equips businesses with the necessary expertise and technology to respond swiftly and capitalize on future opportunities.

Thank you for reading this article! As we've explored, successful peak season logistics strategies require a combination of careful planning, expert execution, and state-of-the-art logistics technology. By partnering with a 3PL provider, businesses can streamline their logistics operations, overcome challenges, and deliver their products with confidence.