Revolutionizing Warehouse Operations with Automation Software

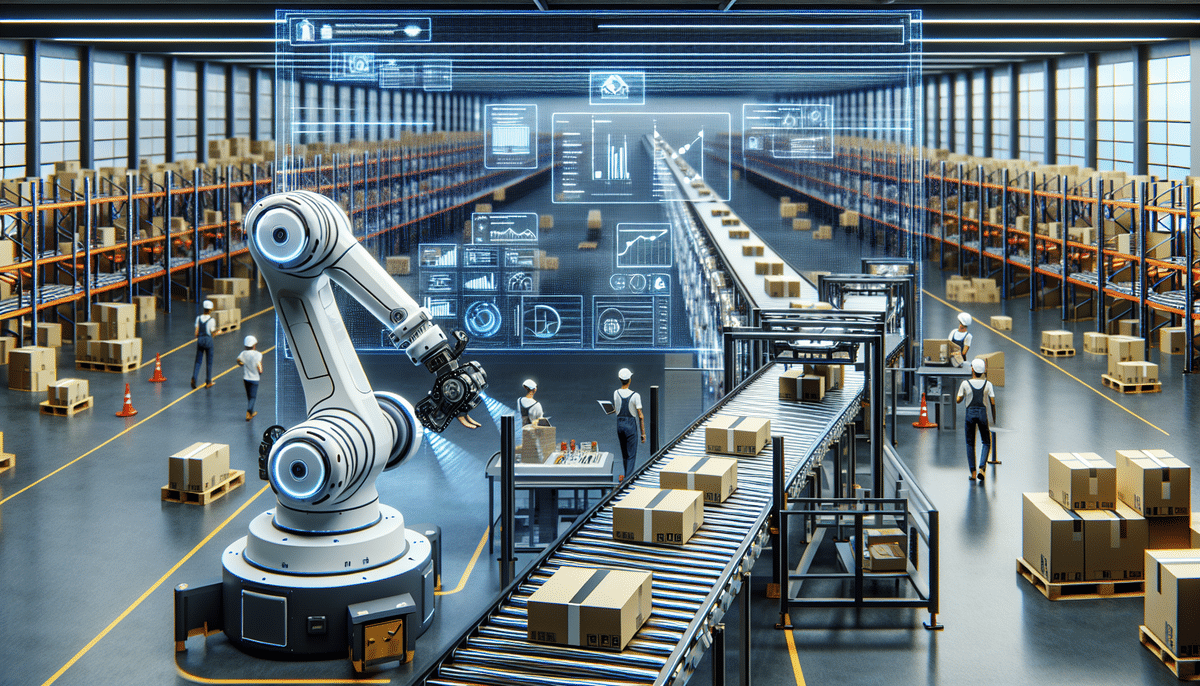

Warehouses have significantly evolved from the days of manual inventory tracking and order fulfillment. The introduction of automation software has enabled warehouses to streamline their processes, maximize productivity, and enhance safety and security. In this article, we explore the advantages of automation software for warehouses, highlight the different types of software available, and analyze case studies of companies that have successfully implemented such software. Additionally, we provide guidance on selecting the right software for your warehouse needs and examine future trends in warehouse operations, emphasizing the pivotal role automation software will play in shaping these developments.

Why Traditional Warehouse Operations are Inefficient

Traditional warehouse operations rely heavily on manual labor, leading to inefficiencies and time-consuming processes. Key challenges include:

- Manual Inventory Tracking: Prone to human error, leading to inaccurate stock levels.

- Order Fulfillment: Time-consuming, increasing order processing times and potential delays.

- Logistics Management: Difficulty in coordinating shipments and deliveries, resulting in increased operational costs.

These inefficiencies can result in:

- Increased Costs: Higher labor costs and potential waste due to errors.

- Reduced Efficiency: Slower operations affecting overall productivity.

- Poor Customer Satisfaction: Delays and inaccuracies in orders can lead to dissatisfied customers.

Moreover, traditional operations often lack real-time visibility into inventory levels and order statuses. According to a 2023 Statista report, manual warehouse processes can increase operational costs by up to 30%. This lack of visibility can result in overstocking or stockouts, leading to lost sales and decreased profitability. Additionally, manual processes make it difficult to swiftly adapt to changes in demand or supply chain disruptions, further impacting the bottom line.

The Advantages of Automation Software for Warehouses

The main advantage of automation software for warehouses is increased efficiency. Automation software can perform many of the manual tasks involved in warehouse operations faster and with greater accuracy. This can free up employees for more complex tasks and reduce the risk of errors in the inventory and order fulfillment processes. In addition, automation software can provide real-time data on inventory levels and order status, allowing for better decision-making and more accurate forecasting.

Another significant advantage is improved safety. By automating tasks such as heavy lifting and transportation of goods, the risk of workplace injuries can be significantly reduced. Furthermore, automation software can monitor and regulate environmental factors such as temperature and humidity, ensuring that products are stored in optimal conditions and reducing the risk of damage or spoilage. Overall, automation software not only increases efficiency and accuracy but also creates a safer and more controlled warehouse environment.

Understanding the Different Types of Automation Software Available

There are several types of automation software available for warehouses, each catering to specific needs and use cases:

- Warehouse Management Systems (WMS): Manage all aspects of warehouse operations, from inventory tracking to order fulfillment.

- Transportation Management Systems (TMS): Oversee the transportation of goods to and from the warehouse.

- Labor Management Systems (LMS): Track employee performance and productivity.

- Cold Chain Management Software: Specialized for temperature-controlled logistics, ensuring products are stored under optimal conditions.

It's crucial to evaluate your warehouse's specific needs before selecting an automation software package. Consider factors such as warehouse size, product types, order volume, and compatibility with existing systems. Ensuring seamless integration can streamline operations, reduce errors, and enhance overall efficiency.

The Benefits of Real-Time Inventory Management with Automation Software

Real-time inventory management is a key benefit of automation software. By providing up-to-the-minute data on inventory levels, automation software enables better decision-making and more accurate forecasting. This capability helps reduce waste and optimize inventory levels, leading to cost savings and improved customer satisfaction.

In addition to inventory management, automation software offers valuable insights into customer behavior and preferences. By analyzing data on customer purchases and browsing history, businesses can tailor their inventory and marketing strategies to better meet customer needs. This personalized approach can lead to increased sales and enhanced customer loyalty.

According to a Forrester Analytics report, businesses that implement real-time inventory management systems see a 20% improvement in inventory accuracy and a 15% reduction in stockouts.

Streamlining Warehouse Processes with Automation Software

Automation software streamlines warehouse processes by automating repetitive tasks and minimizing human error. This allows employees to focus on more complex and value-added activities, enhancing overall productivity. Additionally, automation reduces delays and errors in the supply chain, ensuring smoother operations.

Enhanced communication between different departments is another significant benefit. Automation software facilitates better collaboration, leading to improved efficiency and productivity across the board. Real-time data and analytics provided by the software enable warehouse managers to make informed decisions regarding inventory management, order fulfillment, and shipping, ultimately reducing costs and optimizing operations.

Integrating automation software with other systems, such as Enterprise Resource Planning (ERP) software, offers a comprehensive view of the entire supply chain, further enhancing operational efficiency.

How Automation Software Improves Order Fulfillment and Shipping Accuracy

Automation software enhances order fulfillment and shipping accuracy by automating numerous tasks within these processes. This reduces the risk of errors and delays, leading to improved customer satisfaction. Automation software provides real-time updates on order status and shipping information, facilitating better communication with customers and more precise forecasting.

Furthermore, automation software helps businesses save time and money by streamlining order processing, inventory management, and shipping label generation. By minimizing the need for manual labor, businesses can increase efficiency and productivity while achieving long-term cost savings.

A study by Supply Chain Digital highlights that companies utilizing automation in order fulfillment reduce processing time by up to 50% and achieve shipping accuracy rates exceeding 99%.

Enhancing Warehouse Safety and Security with Automation Software

Enhancing warehouse safety and security is another pivotal benefit of automation software. By automating manual processes, the software reduces the likelihood of accidents, ensuring a safer working environment for employees. Additionally, automation software offers improved tracking and monitoring of inventory and equipment, mitigating risks of theft and loss.

Moreover, automation software can proactively identify potential safety hazards within the warehouse. For instance, if a particular area experiences high traffic, the software can alert managers to implement additional safety measures, such as increased signage or traffic control protocols. By addressing safety concerns proactively, automation software plays a crucial role in preventing accidents and injuries.

According to the Occupational Safety and Health Administration (OSHA), warehouses implementing automation systems report a 25% decrease in workplace accidents.

Maximizing Productivity with Automation Software for Picking and Packing

Picking and packing are critical processes in warehouse operations that benefit immensely from automation software. By automating these tasks, warehouses can significantly boost productivity and reduce error rates. Automation software also improves inventory tracking and monitoring, leading to better forecasting and cost management.

One of the primary advantages is the ability to handle a higher volume of orders. Automation enables warehouses to process orders more swiftly and efficiently, allowing for greater order fulfillment capacity, especially during peak seasons or periods of high demand.

Additionally, automation software offers customization and optimization of the picking and packing processes. By analyzing operational data and identifying patterns, warehouses can refine their processes to enhance efficiency and minimize waste. This results in substantial cost savings and a more streamlined operation overall.

Implementing automation in picking and packing can lead to a 30% increase in productivity and a 20% reduction in error rates, according to recent industry studies.

Case Studies: Companies That Have Successfully Implemented Automation Software in Their Warehouses

Several leading companies have successfully integrated automation software into their warehouse operations, yielding significant improvements in efficiency, productivity, and customer satisfaction:

- Amazon: Utilizes a range of automation technologies, including robotics and automated storage and retrieval systems, to streamline its warehouse operations.

- Walmart: Employs sophisticated supply chain management systems to enhance warehouse efficiency and accuracy.

- DHL: Uses Automated Guided Vehicles (AGVs) to transport goods within its warehouses, increasing speed and reducing manual handling.

- FedEx: Implements robotic systems to sort packages, enhancing speed and accuracy in its distribution centers.

- UPS: Leverages advanced warehouse management systems to improve operations and reduce errors.

These companies demonstrate how effective implementation of automation software can lead to transformative results in warehouse operations.

Choosing the Right Automation Software for Your Warehouse: Factors to Consider

Selecting the appropriate automation software for your warehouse is crucial for maximizing benefits and ensuring seamless operations. Key factors to consider include:

- Operational Size and Complexity: Assess the scale of your warehouse operations and choose software that can handle your specific needs.

- Budget: Determine your budget and find software solutions that offer the best value within your financial constraints.

- Industry-Specific Needs: Consider any specialized requirements unique to your industry, such as cold chain management or hazardous materials handling.

- Customization and Flexibility: Ensure the software can be tailored to fit your unique operational processes.

- Integration Capabilities: Verify that the software can seamlessly integrate with your existing systems, such as ERP or CRM platforms.

- Support and Training: Evaluate the level of support and training provided by the software vendor to facilitate a smooth implementation.

It is advisable to conduct thorough research, evaluate different software packages, and consult with industry experts or review case studies and customer testimonials to understand the software's capabilities and potential benefits fully.

Choosing software that offers a high degree of customization and robust support can significantly enhance the effectiveness of your warehouse operations and ensure a successful implementation.

Future Trends in Warehouse Operations: The Role of Automation Software

The future of warehouse operations is intrinsically linked to advancements in automation software. As technology continues to evolve, warehouses will see even greater levels of automation, driven by innovations such as robotics, drones, artificial intelligence (AI), and machine learning (ML).

- Robotics and Drones: Increasing use of robots for picking, packing, and transporting goods, as well as drones for inventory management and real-time tracking.

- Artificial Intelligence and Machine Learning: Enhanced predictive analytics for demand forecasting, inventory optimization, and process automation.

- Internet of Things (IoT): Integration of IoT devices for real-time monitoring of warehouse conditions and equipment performance.

- Advanced Data Analytics: Leveraging big data to gain deeper insights into operational efficiency and customer behavior.

Automation software will play a critical role in implementing these technologies, enabling warehouses to operate more efficiently, respond swiftly to market changes, and maintain a competitive edge in the logistics industry.

Staying informed about these trends and investing in the appropriate automation technologies will be essential for warehouse owners and managers aiming to optimize their operations and meet the growing demands of the market.

One major benefit of automation software in future warehouse operations is increased efficiency. Automated systems can process orders faster and more accurately, improving customer satisfaction and reducing costs associated with errors and delays. Furthermore, automation software helps optimize inventory management, ensuring optimal stock levels and minimizing the risks of overstocking or stockouts. As the demand for faster and more efficient logistics operations continues to rise, automation software will remain an indispensable tool for warehouse optimization.