Introduction to Proactive Inventory Management

As a business owner, staying competitive and profitable is paramount. Effective inventory management plays a crucial role in achieving these goals by controlling the flow of goods and materials to ensure that products are always available to meet customer demand. In this article, we delve into the advantages of proactive inventory management and its significance for business success.

Benefits of Proactive Inventory Management

Enhancing Operational Efficiency

Proactive inventory management involves planning, monitoring, and adjusting your inventory levels to maintain the right products in stock. This approach helps reduce the risk of stockouts, identify excess inventory, and prevent unnecessary storage and management expenses. According to a Forbes report, businesses implementing proactive inventory strategies saw a 20% increase in operational efficiency and a 15% boost in customer retention rates.

Improving Customer Satisfaction

Furthermore, proactive inventory management boosts customer satisfaction. Consistently having the right products in stock enables quick and efficient fulfillment of orders, fostering customer loyalty and generating positive word-of-mouth referrals.

Optimizing Resource Allocation

- Reduces stockouts and excess inventory

- Optimizes resource allocation

- Minimizes waste and storage costs

- Enhances customer satisfaction and loyalty

- Identifies market trends and demand patterns

Challenges and Solutions in Proactive Inventory Management

The Dangers of Reactive Inventory Management

Reactive inventory management involves addressing inventory issues only after they arise, such as dealing with stockouts or excess inventory. This approach can be costly and time-consuming, often necessitating last-minute orders, expedited shipping, and rush handling. Reactive management can lead to missed sales opportunities, damaged reputations, and loss of customers to competitors.

In contrast, proactive inventory management anticipates demand and plans inventory levels accordingly. This strategy helps prevent stockouts, reduce excess inventory, and optimize the supply chain.

Common Challenges

- Understanding customer demand: Accurately predicting what products customers will need and when.

- Analyzing data effectively: Interpreting large volumes of data to make informed inventory decisions.

- Managing inventory levels efficiently: Balancing sufficient stock to meet demand without overstocking.

To overcome these challenges, businesses should:

- Invest in advanced inventory management technology and analytics tools.

- Establish clear procedures and guidelines for inventory management.

- Provide comprehensive training for employees to ensure they are adept at using inventory systems.

- Continuously monitor and adjust inventory levels and strategies based on real-time data and market trends.

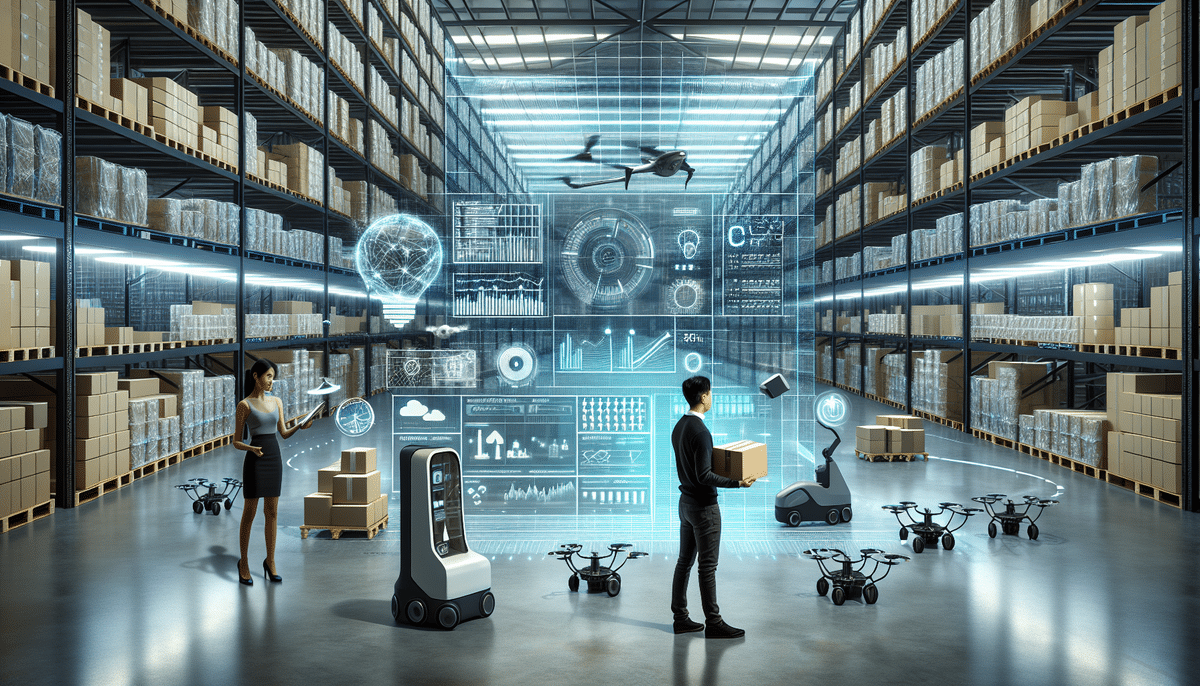

The Role of Technology in Proactive Inventory Management

Technology is integral to proactive inventory management. Inventory management systems, such as Enterprise Resource Planning (ERP) software, provide the tools and data necessary to monitor, adjust, and optimize inventory levels. These systems offer real-time inventory tracking, automate reordering processes, and generate analytics and reports that facilitate informed decision-making.

Additional technologies that support proactive inventory management include:

- Radio Frequency Identification (RFID): Tracks inventory items and monitors their movement throughout the supply chain, providing real-time visibility into inventory levels.

- Artificial Intelligence (AI): Analyzes data from various sources, such as sales trends and customer behavior, to predict demand and optimize inventory levels.

- Internet of Things (IoT): Enables real-time monitoring and data collection from connected devices, enhancing inventory tracking accuracy.

According to a Supply Chain Digital article, businesses leveraging AI for inventory management have seen up to a 25% improvement in demand forecasting accuracy.

Best Practices for Implementing Proactive Inventory Management

Implementing an Effective Inventory Management System

Implementing a proactive inventory management system involves understanding your inventory flow, demand forecasting, and analytics. Key steps include:

- Implementing an ERP system: Integrates various business processes, providing a centralized platform for inventory management.

- Setting inventory thresholds: Defines minimum and maximum stock levels to trigger reordering processes.

- Forecasting demand: Uses historical data and predictive analytics to anticipate future product demand.

- Continuous monitoring: Regularly tracks inventory levels and trends to make necessary adjustments.

Collaboration with your team is essential to establish clear guidelines and procedures. Regularly reviewing and analyzing inventory data helps identify trends and areas for improvement, enabling informed decisions about reordering, prioritizing products, and optimizing inventory levels to meet customer demand while minimizing waste.

Investing in training for your staff ensures that everyone is well-versed in the new system and committed to maintaining optimal inventory levels.

Maintaining Optimal Inventory Levels

- Regular inventory counts: Conduct periodic physical counts to ensure inventory records are accurate.

- Analyze sales data and trends: Use data analytics to understand sales patterns and adjust inventory accordingly.

- Monitor lead times: Keep track of supplier lead times to plan inventory replenishments effectively.

- Establish safety stock levels: Maintain a buffer stock to mitigate the risk of stockouts.

- Adopt just-in-time (JIT) inventory management: Align inventory orders closely with production schedules to reduce holding costs.

Effective communication with suppliers is also crucial. Establishing strong relationships ensures timely updates about potential supply chain disruptions or delays, allowing for prompt adjustments to inventory levels. Additionally, implementing an automated inventory management system can streamline processes such as reordering and tracking, further enhancing inventory accuracy and efficiency.

Regularly reviewing and updating inventory management strategies ensures they remain effective in the face of changing market conditions and customer preferences. Staying informed about the latest inventory management practices and technologies helps businesses maintain optimal inventory levels and stay competitive.

Measuring the Success of Your Proactive Inventory Management Strategy

Evaluating the success of your proactive inventory management strategy involves tracking and analyzing key performance indicators (KPIs). Essential KPIs include:

- Inventory turnover: Measures how often inventory is sold and replaced over a period.

- Order accuracy: Assesses the precision in fulfilling customer orders.

- Customer satisfaction: Gauges customer contentment through surveys and feedback.

- Cost savings: Calculates reductions in costs related to inventory holding, storage, and stockouts.

By setting measurable goals and tracking progress over time, businesses can identify areas for improvement and refine their inventory management strategies for optimal results. Regular performance reviews and adjustments ensure that inventory management remains aligned with business objectives and market demands.

Implementing dashboards and reporting tools can provide real-time visibility into these KPIs, facilitating timely decision-making and continuous improvement. According to a Supply Chain Dive article, businesses that actively measure and manage their inventory KPIs achieve a 35% improvement in inventory accuracy.

The Link Between Proactive Inventory Management and Supply Chain Efficiency

Proactive inventory management is intrinsically linked to supply chain efficiency. By optimizing inventory levels, reducing waste, and improving cash flow, businesses can streamline their supply chains, resulting in faster delivery times and increased customer satisfaction.

Anticipating demand and adjusting inventory levels accordingly helps businesses avoid stockouts and overstocking, which can lead to lost sales and increased costs. Maintaining the right inventory levels also reduces lead times and improves order fulfillment rates, contributing to a more efficient supply chain.

- Optimizes inventory levels

- Reduces waste and excess inventory

- Improves cash flow

- Shortens lead times

- Enhances order fulfillment rates

In addition to efficiency gains, proactive inventory management supports sustainability efforts. By minimizing waste and optimizing inventory levels, businesses can reduce their environmental impact and carbon footprint. Initiatives such as lean inventory practices, using eco-friendly packaging materials, and partnering with sustainable suppliers contribute to a more environmentally responsible supply chain.

A study by McKinsey & Company highlights that companies implementing proactive inventory strategies see a 10% reduction in supply chain-related emissions.

Future Trends in Proactive Inventory Management

The landscape of proactive inventory management is evolving with advancements in technology and data analytics. Future trends include:

- Advanced analytics and machine learning: Enhancing demand forecasting accuracy and inventory optimization.

- Cloud-based inventory management systems: Offering scalability, flexibility, and real-time access to inventory data from any location.

- Internet of Things (IoT) devices: Providing real-time monitoring and data collection for more precise inventory tracking.

As these trends develop, businesses must adapt to leverage these technologies effectively. Embracing advanced analytics and machine learning can provide deeper insights into inventory patterns and customer behavior, enabling more strategic inventory decisions. Cloud-based systems offer increased accessibility and collaboration across different business units, enhancing overall inventory management efficiency.

Integrating IoT devices into inventory management systems can further refine real-time tracking and monitoring, reducing errors and enhancing inventory visibility. Businesses that stay ahead of these trends will be better positioned to optimize their inventory management processes, maintain competitiveness, and drive sustained success.

According to Gartner's 2024 Technology Trends report, companies investing in AI and IoT for inventory management are projected to see a 40% increase in supply chain efficiency over the next five years.

Conclusion

In conclusion, proactive inventory management is vital for business success. By adopting a proactive approach, businesses can optimize inventory levels, reduce waste, improve customer satisfaction, and enhance profitability. Understanding the fundamentals of inventory management, leveraging technology, and implementing best practices enable businesses to achieve greater efficiency, productivity, and growth in today's competitive market.