Introduction to Customizable Automation in Warehousing

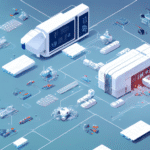

As warehouses continue to evolve and become more complex, businesses are constantly seeking ways to make their operations more efficient and cost-effective. One solution that has gained prominence in recent years is customizable automation. By leveraging the latest technology and innovation, businesses can now implement automation systems tailored to their specific needs, significantly enhancing warehouse management capabilities. In this article, we will provide an in-depth analysis of the benefits of customizable automation and explore how it can unlock the full potential of your warehouse.

Benefits of Customizable Automation

Improved Warehouse Management

One of the primary benefits of customizable automation is the substantial improvement in warehouse management. According to a 2023 McKinsey Operations Report, businesses that implement customizable automation see an average reduction in labor costs by 20% and an increase in product quality by 15%. These systems streamline operations and eliminate inefficiencies, leading to cost savings and enhanced product standards.

Real-Time Inventory Tracking

Additionally, customizable automation systems provide real-time inventory tracking, which aids in accurate forecasting and informed decision-making. With real-time data, businesses can maintain optimal inventory levels, reducing excess stock and minimizing stockouts, ultimately leading to a more profitable and competitive business.

Optimized Space Utilization

Another key advantage is the ability to optimize space utilization. Automating the storage and retrieval of products allows businesses to maximize the use of available space, reducing the need for additional storage facilities. This optimization can result in significant cost savings and increased operational efficiency. Furthermore, customizable automation systems can be tailored to meet specific business needs, offering greater flexibility and adaptability to changing market conditions.

Enhancing Warehouse Efficiency with Automation

Automating Repetitive Tasks

Customizable automation can dramatically enhance efficiency in your warehouse by automating repetitive tasks and saving valuable time. Manual processes such as data entry, scanning, and sorting can be automated, reducing errors and accelerating operations. A study by Gartner shows that warehouses implementing automation can increase their operational speed by up to 30%. Additionally, these systems can easily adapt to workflow changes, ensuring that operations remain optimized at all times.

Real-Time Monitoring and Alerts

With a customizable automation system, you can decrease the time required to complete warehouse tasks, increase accuracy and throughput, and allow staff to focus on higher-level activities. Moreover, these systems enable real-time inventory tracking and monitoring of stock levels. Automated alerts notify you when inventory levels are low, allowing timely restocking and preventing operational delays. Detailed inventory reports generated by these systems facilitate informed purchasing and restocking decisions, further streamlining inventory management and reducing the risk of stockouts.

Implementing Customizable Automation: A Comprehensive Guide

Planning and Considerations

Implementing customizable automation requires meticulous planning to ensure the system aligns with your unique requirements. Key considerations include existing processes, inventory levels, employee skill sets, and overall business objectives. A comprehensive implementation plan should involve robust project management, encompassing a detailed schedule, budget, and contingency plans. Following guidelines from the Forbes Technology Council, businesses can effectively integrate automation systems and maximize their benefits.

Maintenance and Support

One of the significant benefits of customizable automation is increased efficiency. Automating tasks such as picking and packing reduces the time required to complete these activities, boosting overall productivity. Moreover, automation enhances accuracy, leading to fewer returns and higher customer satisfaction rates. However, successful implementation also demands ongoing maintenance and support. It's crucial to have a dedicated team to monitor the system, perform regular maintenance, and address any issues promptly. Proper maintenance ensures the automation system operates smoothly and continues to deliver value over time.

Future Trends and Implications of Automation in Warehousing

Advancements in AI and Machine Learning

Customizable automation is increasingly vital in modern warehouse management. Technological advancements, particularly in artificial intelligence (AI) and machine learning (ML), have made it possible to automate more warehouse processes, a necessity for businesses aiming to stay competitive. According to the Gartner AI Automation Report 2023, AI integration in warehouse automation could lead to a 40% increase in operational efficiency by 2025.

Increased Investment and Accessibility

The 2023 Forrester Report on Warehouse Automation highlights that 70% of warehouses plan to increase their investment in automation technologies over the next five years. Automation technology is becoming more affordable and accessible, enabling businesses of all sizes to adopt customizable automation systems. This trend is driving widespread adoption and innovation in the warehousing sector.

Choosing the Right Automation System

Evaluating Functionality and Flexibility

Choosing the right customizable automation system is critical to the success of your warehouse operations. It is essential to evaluate systems based on functionality, flexibility, ease of use, and integration capabilities. Businesses should assess vendors for their track record, customer service, and technical support. Resources such as the Society for Human Resource Management's Selection Guide can aid in making informed decisions.

Vendor Selection and Training

Selecting the right vendor is crucial for ensuring the quality and reliability of the automation system. Additionally, ensure that your employees possess the necessary skills to operate and maintain the automation system. Providing comprehensive training can facilitate a smoother transition and maximize the system's benefits.

Real-World Success Stories

Alibaba's Smart Warehouse

Alibaba's Smart Warehouse, equipped with cutting-edge automation technology, can process over 1 million orders per day, showcasing the immense potential of automation in handling high-volume operations. The integration of IoT and AI technologies has significantly enhanced operational efficiency and accuracy.

DHL's Advanced Automation Systems

DHL's advanced automation system, which utilizes smart conveyor belts and robotics, has increased productivity by 25% while reducing operational costs. These examples underscore the effectiveness and transformative impact of customizable automation in modern warehouse management.

Overcoming Challenges in Automation Implementation

Managing Costs

While customizable automation offers numerous benefits, its implementation can present challenges such as high upfront costs, resistance to change, and the need for specialized expertise. To overcome these obstacles, businesses should clearly communicate the benefits and reasons for implementing automation systems to all stakeholders, fostering a culture of acceptance and support.

Change Management

Ensuring employee buy-in is essential for the successful adoption of automation technologies. Providing comprehensive training and involving employees in the implementation process can help mitigate resistance and facilitate a smoother transition. Additionally, selecting the right vendor and developing a phased implementation plan can manage costs and mitigate risks, ensuring a successful integration of automation systems.

Conclusion

Customizable automation has the potential to transform your warehouse operations by enhancing efficiency, reducing costs, and improving accuracy. With its numerous benefits and capacity for growth, customizable automation is a game-changer for businesses of all sizes. By leveraging automation systems, businesses can optimize warehouse management, unlock their full potential, and improve their overall bottom line.

As automation technology continues to advance, it is essential for businesses to adopt these innovative warehouse management systems to remain competitive and drive sustainable growth. Implementing customizable automation not only enhances operational performance but also positions businesses for future success in an increasingly dynamic market landscape.