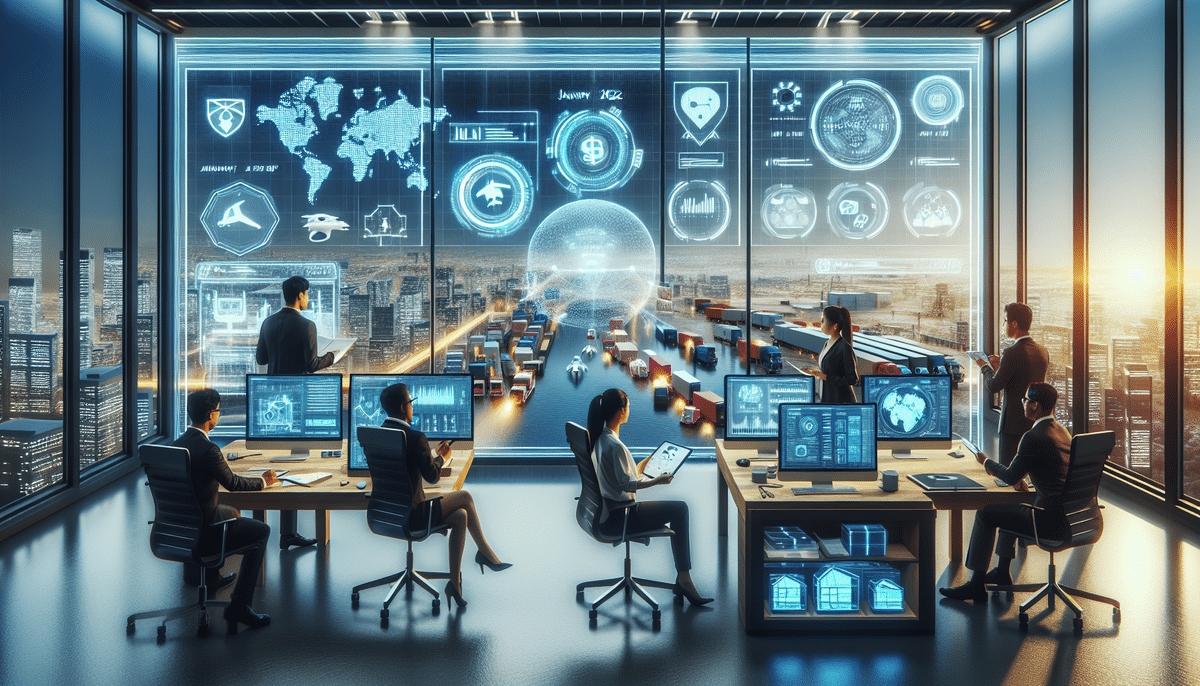

January 2023 Supply Chain Tech Monthly Roundup

Welcome to the January 2023 Supply Chain Tech Monthly Roundup, where we provide a comprehensive overview of the top supply chain technology trends shaping the industry this month. As we continue to navigate a rapidly evolving business landscape, staying abreast of the latest technological advancements is crucial for optimizing supply chain operations. In this article, we explore emerging technologies, innovations, and trends that are transforming the supply chain landscape. Here are the key sections we cover:

Top Supply Chain Trends in 2023

Accelerated Digitization and AI Integration

One of the most critical trends in 2023 is the accelerated digitization of supply chain operations. Enhanced digital tools are enabling more reliable processes and accurate tracking, essential for operational efficiency. The adoption of artificial intelligence (AI) and machine learning (ML) continues to expand, driving advancements in network optimization and efficiency maximization. According to a McKinsey report, companies leveraging AI for supply chain forecasting have seen up to a 15% improvement in forecasting accuracy.

Cloud Computing and Remote Collaboration

Cloud computing solutions remain a significant trend, especially as remote and hybrid work models persist beyond the COVID-19 pandemic. Cloud-based platforms facilitate seamless collaboration and data sharing across supply chain stakeholders, enhancing agility and responsiveness.

Sustainability and Green Supply Chains

The increased focus on sustainability in supply chain management is another prominent trend. Organizations are prioritizing the reduction of their carbon footprint by implementing eco-friendly practices, such as utilizing renewable energy sources, minimizing waste, and adopting circular economy principles. A recent study by Supply Chain Digital highlights that 72% of companies are integrating sustainability into their core supply chain strategies.

Supply Chain Resilience and Risk Management

Supply chain resilience remains a top priority as businesses seek to mitigate risks and adapt to unforeseen disruptions. Investment in risk management strategies, such as diversifying suppliers and maintaining strategic inventory levels, is essential to ensure continuity and meet customer demand consistently. The ongoing geopolitical tensions and climate-related challenges further underscore the necessity of resilient supply chain frameworks.

Innovations in Supply Chain Technologies

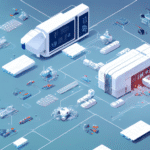

Automated Warehousing Solutions

Automated warehousing technology continues to evolve, ushering in a new era of efficiency and productivity. The integration of automated conveyor systems has significantly increased warehouse throughput and accuracy. Robotics for automated order picking, packing, and replenishment are becoming standard, reducing labor costs and expediting order processing times. According to Robotics Business Review, the global market for warehouse robotics is expected to grow by 20% annually through 2025.

Autonomous Mobile Robots (AMRs) are gaining traction for their versatility in material handling, inventory management, and order fulfillment. These robots navigate autonomously within warehouses, enhancing operational flexibility and reducing dependency on human intervention.

Blockchain for Transparency and Efficiency

Blockchain technology offers substantial benefits in supply chain management, particularly in enhancing transparency, efficiency, and traceability. By employing distributed ledger technology (DLT), blockchain ensures secure and tamper-proof data sharing among supply chain participants. This enables stakeholders to track assets, products, and transactions from origin to end-user, mitigating risks related to fraud, theft, and counterfeiting. The use of smart contracts facilitates automated transactions and payments, streamlining processes and reducing transactional delays and costs.

According to a study by IBM Blockchain, supply chains utilizing blockchain technology have seen a 30% improvement in transparency and a 20% increase in operational efficiency.

Internet of Things (IoT) Integration

The deployment of Internet of Things (IoT) devices within supply chains provides real-time data on inventory levels, equipment performance, and environmental conditions. This data-driven approach allows for proactive maintenance, reducing downtime and enhancing overall operational efficiency. According to IBM IoT, predictive maintenance powered by IoT can decrease maintenance costs by up to 30% and reduce equipment downtime by 25%.

Advanced Inventory Management Systems

Effective inventory management is vital for maintaining a streamlined supply chain. The adoption of RFID (Radio-Frequency Identification) technology enables real-time tracking of inventory, providing enhanced visibility and accuracy. Advanced algorithms and predictive analytics are optimizing inventory levels by analyzing historical data and market trends to forecast demand accurately. According to a report by Gartner, predictive analytics in inventory management can lead to a 15% reduction in inventory holding costs.

Advancements in Logistics and Last-Mile Delivery

Logistics Software Innovations

Advancements in logistics software are mitigating disruptions by enhancing the speed and accuracy of deliveries. Transportation Management Systems (TMS) have evolved with real-time tracking capabilities, enabling efficient monitoring of freight movements and improving overall logistics management. Innovations in predictive analytics and machine learning algorithms empower logistics experts to anticipate capacity constraints and optimize delivery routes proactively. A Forbes article highlights that the use of predictive analytics in logistics can enhance delivery efficiency by up to 18%.

Growing Demand for Last-Mile Delivery Solutions

Last-mile delivery remains a critical component of the supply chain, often accounting for up to 50% of the total delivery costs. With the continuous growth of e-commerce and heightened customer expectations for swift and reliable deliveries, the demand for efficient last-mile delivery solutions is surging. In 2023, there is increased experimentation with innovative technologies such as robots and drones for last-mile delivery, offering the potential to reduce delivery times and operational costs. A study by Logistics Management reveals that implementing advanced last-mile delivery solutions can decrease delivery costs by up to 15% and improve on-time delivery rates by 20%.

Digital Transformation and E-Commerce Impact

Embracing Digital Transformation

Digital transformation remains a critical imperative for modernizing supply chain management and maintaining competitiveness in today’s dynamic business environment. This transformation involves integrating cutting-edge technologies, including AI, IoT, and cloud computing, into every facet of the supply chain. By adopting digital tools, businesses can create smart, connected supply chains that offer enhanced forecasting and planning capabilities. According to a report by McKinsey & Company, companies that have embraced digital transformation in their supply chains have seen a 25% improvement in operational efficiency and a 20% reduction in costs.

Impact of E-Commerce on Logistics

The e-commerce sector continues to experience rapid growth, fundamentally altering the logistics landscape. As consumers increasingly rely on online platforms for their purchases, the demand for fast and reliable delivery services intensifies. Advancements such as automated order processing, AI-powered chatbots for customer service, and drone delivery systems are becoming more prevalent, driving efficiency and enhancing the customer experience. A report by Forrester indicates that the integration of advanced technologies in e-commerce can lead to a 20% increase in operational efficiency and a 25% boost in customer satisfaction rates.

Sustainability and Green Technologies

Implementing Green Supply Chain Practices

Sustainability has become a cornerstone for businesses globally, and the supply chain is no exception. The adoption of green technologies is enabling supply chain operators to reduce their environmental impact and promote eco-friendly practices. Electric vehicles (EVs) are increasingly being utilized for transportation and logistics, significantly cutting down on carbon emissions compared to traditional fuel-powered vehicles.

Renewable energy sources, such as solar and wind power, are being integrated into supply chain operations, powering warehouses and distribution centers with clean energy. Sustainable procurement practices, including the selection of raw materials and product components from environmentally responsible suppliers, are gaining importance. These practices not only reduce the carbon footprint but also enhance the company's reputation and compliance with environmental regulations.

Consumer and regulatory pressure is driving businesses to prioritize sustainability in their supply chain strategies. According to a survey by Supply Chain Digital, 68% of companies have increased their investment in sustainable supply chain technologies in the past year.

Case Studies and Future Outlook

Successful Implementation of Supply Chain Technologies

Numerous organizations have successfully implemented supply chain technology solutions, yielding impressive results and setting benchmarks for industry standards. For example, The Home Depot has deployed Automated Guided Vehicles (AGVs) to transport large and bulky products across its fulfillment centers. This implementation has significantly reduced manual labor costs and increased operational efficiency. According to The Home Depot's annual report, the use of AGVs has improved fulfillment center productivity by 30%.

Another notable example is PepsiCo, which utilizes predictive modeling tools and machine learning algorithms to optimize its demand forecasting processes. This approach has enhanced cost controls and streamlined production scheduling, enabling PepsiCo to meet consumer demand more effectively. A case study by PepsiCo highlights a 15% increase in demand forecasting accuracy due to these technological advancements.

These case studies underscore the importance of innovation and creativity in addressing evolving supply chain challenges. By leveraging advanced technologies, businesses can enhance their operational capabilities, reduce costs, and improve customer satisfaction.

Future Outlook and Emerging Technologies

Looking ahead, several emerging technologies are set to disrupt and transform supply chain operations. These include drones, autonomous vehicles, and continued advancements in blockchain technology. These innovations facilitate more efficient and cost-effective communication and operations among suppliers, manufacturers, and retailers, streamlining supply chain processes.

The use of drones and autonomous vehicles for last-mile delivery is gaining momentum, enhancing delivery speed and accuracy while reducing operational costs. Companies like Amazon and UPS are investing heavily in drone delivery systems to meet the increasing demand for rapid and reliable delivery services. According to a Forbes report, the adoption of drone technology in supply chains can reduce delivery times by up to 40%.

However, the practical implementation of some emerging technologies faces challenges such as regulatory limitations and high initial investment costs. Businesses must navigate these obstacles to fully leverage the benefits of these technologies. Ongoing research and development, along with supportive regulatory frameworks, will be essential for the widespread adoption of these transformative technologies.

Conclusion

The supply chain landscape continues to be dynamic and rapidly evolving, driven by technological advancements and shifting market demands. This January 2023 Supply Chain Tech Monthly Roundup has highlighted the latest innovations, trends, and technologies poised to transform the supply chain ecosystem. From the widespread adoption of artificial intelligence and machine learning for inventory optimization to the impact of blockchain and IoT on fulfillment and asset management, there are numerous exciting developments on the horizon.

Businesses must remain agile and proactive in embracing these technological advancements to stay competitive and meet the evolving needs of their customers. At Supply Chain Tech Monthly Roundup, we are committed to keeping you informed about the latest trends and innovations that will shape the future of supply chain management.