How to Optimize Your Warehouse Layout for Order Fulfillment

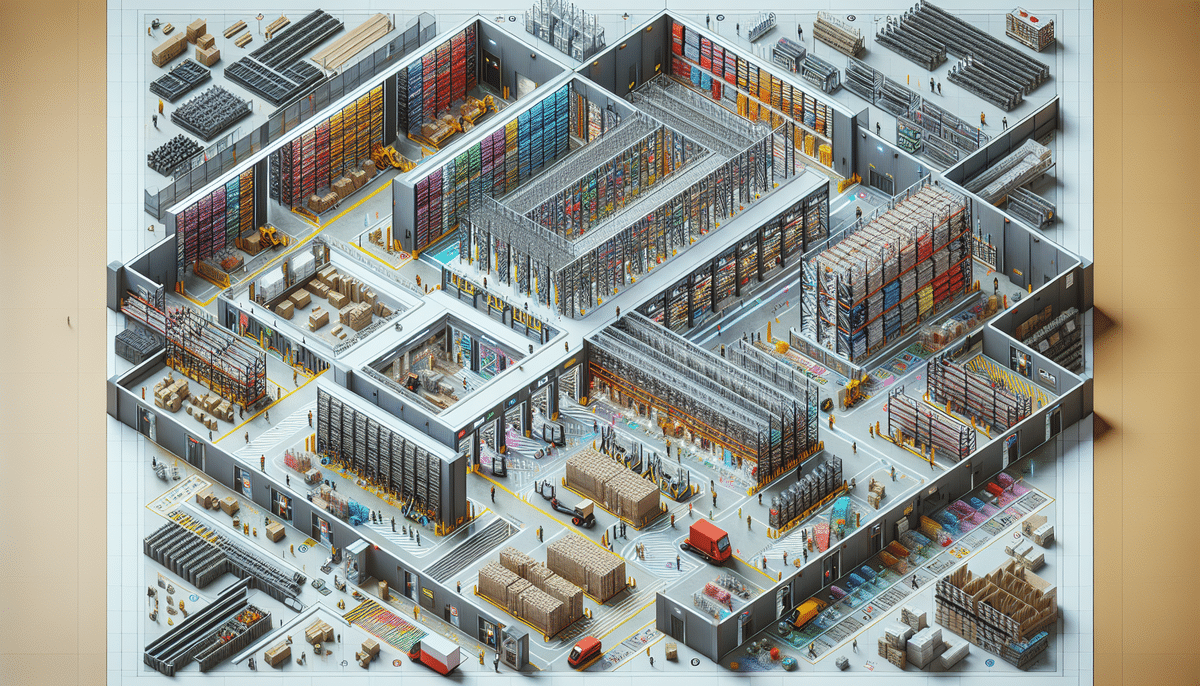

Efficient and effective order fulfillment is a critical component of any successful business operation. A well-designed and optimized warehouse layout plays a pivotal role in achieving this efficiency. In this article, we will delve into the key factors to consider when optimizing your warehouse layout for order fulfillment, including space utilization, storage solutions, picking systems, inventory management, productivity, and safety. We will also discuss common mistakes to avoid and strategies for continuous improvement.

The Importance of a Well-Designed Warehouse Layout

A well-designed warehouse layout is essential for a successful order fulfillment operation. It facilitates the efficient movement of products, reduces order processing time, and boosts overall productivity. Conversely, a poorly designed layout can lead to suboptimal space utilization, excessive travel time, and decreased productivity. Additionally, it can create safety hazards and negatively impact employee morale.

One critical aspect of an effective warehouse layout is the strategic placement of inventory. Proper placement can significantly reduce the time employees spend locating and retrieving products. Implementing a logical numbering or labeling system and grouping similar products together are effective strategies. Furthermore, the layout should prioritize easy access to high-demand items while relegating low-demand items to less accessible areas to maximize space utilization.

According to industry reports, optimized warehouse layouts can increase productivity by up to 25% (ShipScience Warehouse Optimization Report).

Understanding Your Warehouse Space

The first step in optimizing your warehouse layout is to thoroughly understand your available space. This includes assessing the size, height, and shape of the warehouse, as well as identifying any obstacles or constraints that may impact your layout. Additionally, it's vital to consider the flow of products throughout the warehouse, from receiving to storage to picking and shipping.

Another crucial factor is the type of products being stored. Different products may require varying storage conditions, such as temperature control or specialized shelving. Accounting for these requirements ensures that products are stored safely and efficiently, reducing the risk of damage and improving retrieval times.

For more insights on space utilization, refer to the Space Utilization Tips by ShipScience.

Efficient Use of Vertical Space in Your Warehouse

Vertical space is often underutilized in warehouse optimization. By leveraging the height of your warehouse, you can significantly increase storage capacity and reduce the operational footprint. Implementing mezzanines, vertical shelving, and automated storage and retrieval systems are effective ways to maximize vertical space.

Utilizing vertical space not only boosts storage capacity but also enhances workflow and productivity. Storing items vertically can decrease the time and effort required to locate and retrieve items, particularly high-demand products. Additionally, vertical storage helps maintain an organized warehouse, reducing the risk of accidents caused by cluttered aisles and walkways.

Studies have shown that maximizing vertical space can lead to a 15% increase in storage capacity (Vertical Space Study by ShipScience).

Choosing the Right Storage Solutions for Your Warehouse

Selecting appropriate storage solutions is vital for optimizing your warehouse layout. Options include pallet racking, carton flow systems, and shelving units. When choosing storage solutions, consider the size and weight of your inventory, as well as the frequency of handling. Accessibility and visibility are also key to ensuring efficient picking and restocking processes.

The type of inventory stored also influences storage solution selection. For instance, perishable items may require refrigerated storage, while hazardous materials necessitate storage solutions that comply with safety regulations.

Additionally, consider the future growth of your business. Invest in storage systems that are scalable and can be easily expanded or reconfigured to accommodate increasing inventory volumes.

Explore various storage options in the Storage Solutions Guide provided by ShipScience.

How to Design an Effective Picking System

The picking system is the core of any order fulfillment operation. A well-designed system enhances both productivity and accuracy. Common picking methods include zone picking, batch picking, and wave picking. When designing your picking system, consider the size and type of your inventory, as well as the overall layout of your warehouse.

Incorporating technology, such as pick-to-light and voice-guided picking systems, can further increase efficiency and accuracy. These technologies guide pickers to the correct locations and streamline the picking process.

It's also essential to consider the skill level of your employees. For warehouses with high employee turnover or temporary workers, a simple and intuitive picking system is advantageous. Conversely, warehouses with experienced staff may implement more complex systems that offer greater customization and flexibility.

For advanced picking system designs, refer to the Picking Systems Overview by ShipScience.

Best Practices for Inventory Management in Your Warehouse

Effective inventory management is crucial for order fulfillment efficiency and accuracy. Implementing strategies such as cycle counting, ABC analysis, and just-in-time inventory management can significantly enhance performance. Establishing clear inventory management procedures and utilizing technology like barcode scanning and RFID tracking ensures accurate and timely inventory control.

Proper storage and organization are also vital. This includes labeling and categorizing items, as well as storing items in appropriate locations based on their size, weight, and usage frequency. An organized inventory reduces retrieval times and minimizes the risk of errors or lost items.

Regularly reviewing and analyzing inventory data helps identify trends and inform decision-making. Analyze sales data to determine product popularity and monitor inventory levels to maintain optimal stock without overstocking.

Learn more about inventory management best practices in the Inventory Management Guide by ShipScience.

How to Minimize Travel Time and Increase Productivity in Your Warehouse

Reducing travel time within the warehouse is essential for optimizing order fulfillment. Strategies include designing efficient pick paths, minimizing walking distances, and implementing optimized slotting for inventory placement. Additionally, leveraging technology such as conveyor systems and automated guided vehicles can further decrease travel time and boost productivity.

Implementing a zone picking strategy, which divides the warehouse into specific zones assigned to designated pickers, reduces the time pickers spend moving between different warehouse areas. This approach can significantly enhance overall productivity.

Prioritizing worker safety is equally important. Implementing safety protocols, providing comprehensive training, and using equipment like safety barriers and personal protective equipment create a safer work environment, thereby supporting efficient operations.

For strategies on minimizing travel time, refer to the Minimizing Travel Time Strategies by ShipScience.

Creating a Safe and Ergonomic Workplace in Your Warehouse

Ensuring a safe and ergonomic workplace is fundamental to maintaining a productive and healthy workforce. Utilize ergonomic equipment such as adjustable workstations and lift tables to reduce the risk of injury. Establish clear safety procedures and provide comprehensive training on safe work practices.

Proper lighting and ventilation are critical for a healthy work environment. Adequate lighting prevents eye strain and accidents, while effective ventilation mitigates respiratory issues. Regular maintenance of lighting and ventilation systems is essential.

Encouraging employees to take breaks and perform stretching exercises throughout the day helps prevent muscle strain and fatigue. Providing designated break areas supports employee well-being and maintains high productivity levels.

Explore ergonomic workplace solutions in the Ergonomic Solutions Guide by ShipScience.

Utilizing Technology to Improve Order Fulfillment Efficiency

Incorporating technology can greatly enhance order fulfillment efficiency, encompassing inventory management, picking, and shipping processes. Warehouse management software, automation systems, and mobile devices are indispensable tools for modern warehouses. Selecting the right technology and ensuring proper training are crucial for successful implementation.

Barcode scanning is one of the most widely adopted technologies in order fulfillment. It reduces errors in picking and packing, improves inventory accuracy, and facilitates real-time inventory tracking. By scanning barcodes, workers can quickly identify the correct products and ensure accurate shipping.

Advanced technologies such as warehouse automation and robotics are also transforming order fulfillment operations, providing faster and more reliable processes.

Discover the latest technological advancements in order fulfillment in the Technology in Warehousing article by ShipScience.

Tips for Maintaining an Organized and Clean Warehouse

An organized and clean warehouse is vital for maximizing productivity and minimizing safety hazards. Implement visual management tools like color-coded labels and floor tape to clearly designate inventory locations and traffic lanes. Establish a regular cleaning and maintenance schedule to ensure the warehouse remains orderly.

Training employees on proper cleaning procedures and emphasizing the importance of maintaining a clean workspace fosters a culture of organization and safety. Regular audits and inspections can help identify areas that need improvement and ensure adherence to cleanliness standards.

For effective warehouse organization tips, refer to the Warehouse Organization Tips by ShipScience.

Measuring Success: Key Performance Indicators (KPIs) for Order Fulfillment

Measuring the success of your order fulfillment operations is essential for identifying improvement opportunities and ensuring ongoing optimization. Key performance indicators (KPIs) such as order processing time, inventory accuracy, and employee productivity provide valuable insights into operational performance.

Establishing clear performance metrics and regularly monitoring them allows you to track progress and implement necessary changes. Analyzing KPI data helps uncover inefficiencies and informs strategic decisions to enhance overall performance.

Common KPIs to track include:

- Order Processing Time

- Inventory Accuracy

- Pick and Pack Accuracy

- Employee Productivity

- Return Rates

Learn more about selecting and tracking KPIs in the KPI Guide by ShipScience.

Common Mistakes to Avoid When Optimizing Your Warehouse Layout

Despite best efforts, several common mistakes can hinder warehouse layout optimization. These include overloading shelves beyond their capacity, neglecting workflow efficiency, and overlooking potential safety hazards.

Other pitfalls include inadequate planning for future growth, failing to incorporate employee feedback, and underutilizing available technology. Regularly reviewing and adjusting your warehouse layout helps prevent these mistakes and maintains optimal efficiency and productivity.

For a comprehensive list of common mistakes and how to avoid them, visit the Warehouse Layout Mistakes page by ShipScience.

Continuous Improvement: Strategies for Adapting Your Warehouse Layout Over Time

Warehouse optimization is an ongoing process that must evolve with your business's growth and changing demands. Periodically reviewing your layout allows you to identify areas for improvement and implement incremental changes to enhance efficiency.

Strategies for continuous improvement include:

- Regularly analyzing operational data to identify trends and inefficiencies

- Soliciting feedback from employees to uncover practical insights

- Staying updated with the latest industry trends and technological advancements

- Implementing pilot programs to test new layout designs or technologies before full-scale adoption

Adopting a mindset of continuous improvement ensures that your warehouse layout remains optimized and supports your business's long-term success.

Explore continuous improvement strategies in the Continuous Improvement Strategies by ShipScience.

Conclusion: Steps You Can Take Today to Optimize Your Warehouse Layout for Order Fulfillment

Optimizing your warehouse layout for order fulfillment is a fundamental aspect of a successful business operation. By thoroughly understanding your space, selecting the right storage solutions, designing an effective picking system, managing inventory efficiently, and prioritizing safety and productivity, you can create a well-optimized warehouse layout that maximizes efficiency and profitability.

Remember to consistently measure performance using relevant KPIs and continuously seek opportunities for improvement. Start by analyzing your current layout to identify areas for enhancement and implement strategic changes to drive better results.

Your business will benefit from improved operational efficiency, reduced costs, and increased customer satisfaction.

For more resources and expert advice on warehouse optimization, visit the ShipScience Resources page.