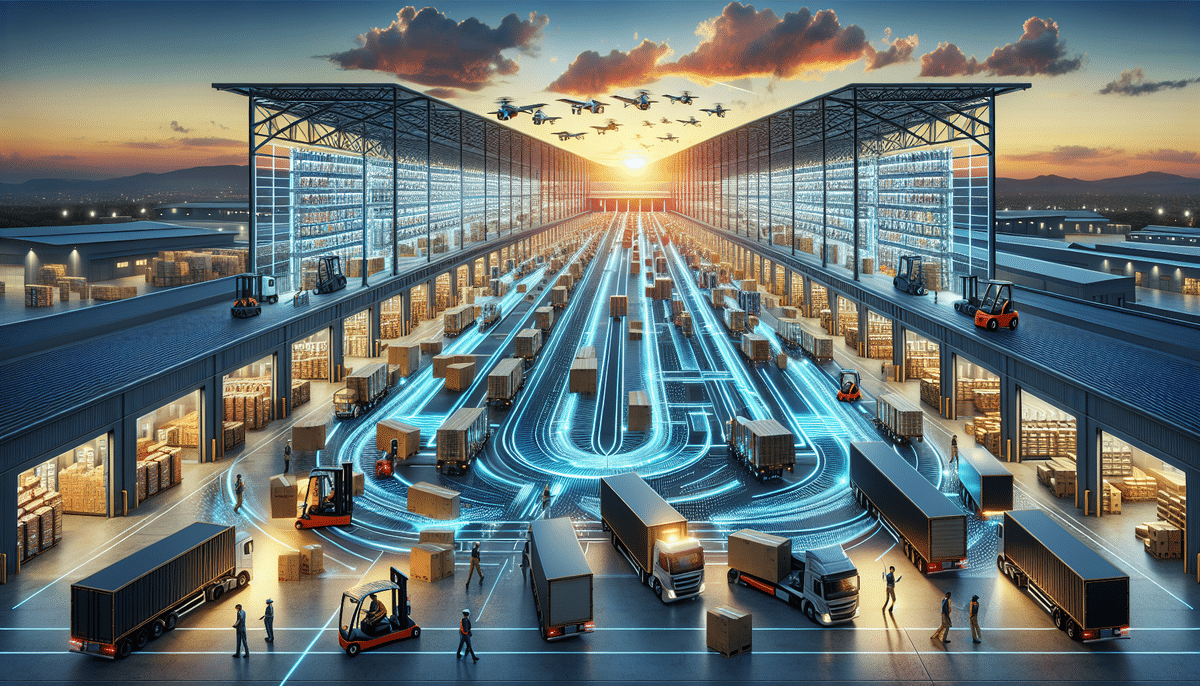

Understanding the Benefits of Cross-Docking for Logistics and Supply Chain Management

Effective logistics management is a vital aspect of running a successful business. Businesses must find ways to optimize their supply chain processes to enhance efficiency and reduce costs. One popular technique that businesses are adopting to improve their logistics and supply chain management is cross-docking.

How Cross-Docking Can Reduce Transportation Costs for Businesses

Cross-docking is an innovative logistics strategy that involves directly transporting products from the inbound dock to the outbound dock without being stored in a warehouse. By eliminating intermediate storage, cross-docking significantly reduces transportation, storage, and inventory costs.

- Cost Savings: Businesses save on transportation costs as there is no need to maintain extensive warehouse facilities.

- Inventory Reduction: Lower inventory holding costs allow businesses to invest more resources in other areas of the supply chain, enhancing overall efficiency.

- Risk Mitigation: Reduces the risk of product damage or loss since products are handled less during transit.

According to a 2023 Supply Chain Report, companies implementing cross-docking have reduced their logistics costs by up to 15%.

Improving Efficiency in Warehouse Operations with Cross-Docking

Implementing cross-docking strategies in warehouse operations can significantly improve efficiency by streamlining the supply chain and reducing the need for material handling equipment. This allows businesses to unload and load shipments quickly, enhancing order fulfillment speeds.

- Just-In-Time Inventory: Supports a just-in-time (JIT) inventory system, reducing the need for excess stock.

- Enhanced Supply Chain Visibility: Improves visibility and reduces the risk of stockouts by ensuring products move swiftly through the warehouse.

Studies show that businesses utilizing cross-docking experience a 30% increase in order processing speed (ShipScience Research).

The Role of Technology in Optimizing Cross-Docking Processes

Advanced technologies such as barcode scanning and RFID have significantly enhanced the effectiveness of cross-docking strategies. These technologies enable accurate tracking and shipment management, leading to better inventory control and warehouse management.

- Automated Material Handling Systems: Use conveyors, sorters, and robots to move products efficiently, reducing the need for manual labor.

- Real-Time Data Analysis: Provides businesses with real-time data to make informed decisions, enhancing overall supply chain responsiveness.

According to ShipScience Technology Insights, companies leveraging automation in cross-docking have seen a 25% increase in operational efficiency.

Cross-Docking vs Traditional Warehousing: Which is Better?

Cross-docking and traditional warehousing represent two distinct approaches to supply chain management. Traditional warehousing involves storing products before distribution, while cross-docking streamlines the process by eliminating intermediate storage.

- Cross-Docking: Ideal for businesses requiring faster supply chain processes, reduced storage costs, and improved efficiency.

- Traditional Warehousing: Better suited for perishable goods, fragile items, and products with specific storage requirements.

Businesses should evaluate their specific needs and product requirements to determine the most suitable approach. For more insights, refer to the Warehouse Management Guide.

Reducing Inventory Holding Costs with Cross-Docking Strategies

Inventory holding costs can significantly impact a company's profitability. Cross-docking helps mitigate these costs by eliminating the need for storage space and enabling a lean inventory system.

- Improved Cash Flow: Reduced inventory levels free up capital for other investments.

- Minimized Obsolescence: Lower inventory reduces the risk of holding outdated or unsellable products.

- Enhanced Customer Satisfaction: Faster product delivery times improve customer satisfaction and loyalty.

Implementing cross-docking can lead to a 20% reduction in inventory costs, as highlighted in the Cost Analysis Report.

Enhancing Customer Satisfaction through Efficient Cross-Docking Practices

Cross-docking shortens the time products take to reach customers by streamlining the supply chain process. This reduction in transit time enhances order fulfillment rates, leading to higher customer satisfaction levels.

- Faster Delivery: Products are quickly sorted and loaded onto outbound trucks, ensuring timely delivery.

- Cost Efficiency: Reduced inventory and storage costs can be passed on to customers, making products more competitively priced.

- Sustainability: Efficient cross-docking practices contribute to a more sustainable supply chain by minimizing carbon emissions and energy consumption.

According to customer reviews, businesses utilizing cross-docking report a 15% increase in customer satisfaction scores.

The Environmental Benefits of Cross-Docking for Sustainable Supply Chain Management

Cross-docking offers significant environmental benefits, making it a sustainable supply chain management practice:

- Reduced Carbon Emissions: Optimizes shipment routes, lowering transportation-related carbon emissions.

- Energy Conservation: Less energy is used in warehouses due to reduced storage requirements.

- Waste Minimization: Decreases product spoilage and damage, reducing waste in the supply chain.

- Packaging Efficiency: Consolidates shipments, resulting in less packaging material usage.

Implementing cross-docking strategies can help companies achieve their sustainability goals. For more information, visit the Sustainability Page.

Implementing a Successful Cross-Docking Strategy: Tips and Best Practices

To successfully implement a cross-docking strategy, businesses should adhere to the following best practices:

- Optimize Shipment Schedules: Ensure timely arrivals and departures to prevent bottlenecks.

- Reliable Transportation: Partner with dependable carriers to maintain consistent delivery schedules.

- Advanced Technology Systems: Utilize automation and real-time tracking to enhance operational efficiency.

- Effective Communication: Establish strong communication channels with suppliers, carriers, and customers.

- Facility Layout: Design warehouses to facilitate smooth flow of goods using conveyor belts and automated sorting systems.

- Workforce Training: Ensure employees are well-trained in handling and sorting goods efficiently.

Adopting these practices can lead to significant improvements in supply chain efficiency and cost reduction. Refer to the Best Practices Guide for more detailed strategies.

Mitigating Risks and Challenges in Cross-Docking Operations

While cross-docking offers numerous benefits, businesses may encounter several challenges during implementation:

- Transportation Delays: Unreliable transportation can disrupt the cross-docking process.

- Communication Breakdowns: Poor communication can lead to errors and inefficiencies.

- Operational Errors: Increased handling can result in mistakes if not managed properly.

- External Factors: Weather conditions, traffic, and other unforeseen events can impact operations.

To mitigate these risks, businesses should:

- Invest in Reliable Technologies: Implement robust tracking and management systems.

- Establish Strong Communication Protocols: Ensure clear and consistent communication with all stakeholders.

- Develop Contingency Plans: Prepare for potential disruptions by having backup plans in place.

- Enhance Supply Chain Visibility: Use real-time tracking to monitor and control the entire supply chain effectively.

For comprehensive risk management strategies, visit our Risk Management Section.

Understanding the Different Types of Cross-Docking to Choose the Right Strategy for Your Business

There are several types of cross-docking, each suited to different business needs:

- Opportunistic Cross-Docking: Utilizes cross-docking on an as-needed basis based on seasonal demands or unexpected surges.

- Scheduled Cross-Docking: Involves regular, scheduled shipments that follow a predetermined timetable.

- Flow-Through Cross-Docking: Products flow directly from inbound to outbound docks with minimal or no storage time.

Choosing the right type depends on your business requirements, product types, and supply chain dynamics. Consulting with experienced supply chain professionals can help in selecting the most effective strategy. Learn more in our Types of Cross-Docking Guide.

Case Studies: Companies that Successfully Implemented Cross-Docking Strategies

Several leading companies have effectively implemented cross-docking strategies to enhance their supply chain operations:

- Walmart: Utilizes cross-docking to streamline its vast supply chain, reducing delivery times and lowering costs.

- Amazon: Employs cross-docking in its fulfillment centers to expedite order processing and improve customer satisfaction.

- Toyota: Applies cross-docking in its just-in-time manufacturing approach to minimize inventory levels.

These companies have achieved significant competitive advantages by adopting cross-docking, including improved efficiency, reduced costs, and enhanced customer satisfaction.

Read more about their strategies in our Case Studies Section.

Measuring the ROI of Cross-Docking for Your Business

Determining the return on investment (ROI) for cross-docking involves assessing the total costs of implementation against the benefits achieved:

- Cost Savings: Calculate reductions in transportation, storage, and inventory holding costs.

- Efficiency Gains: Measure improvements in order processing speed and fulfillment rates.

- Customer Satisfaction: Evaluate increases in customer satisfaction and loyalty metrics.

A successful cross-docking strategy should demonstrate a positive ROI by lowering operational costs and enhancing overall business performance. For detailed ROI analysis methods, refer to our ROI Analysis Guide.

Future Trends and Innovations in the World of Cross-Docking and Supply Chain Management

The supply chain industry is continually evolving, with cross-docking remaining a key focus area. Future trends and innovations include:

- Artificial Intelligence (AI): Enhancing predictive analytics for better demand forecasting and inventory management.

- Blockchain Technology: Improving transparency and traceability in the supply chain.

- Automation and Robotics: Further automating cross-docking processes to increase speed and accuracy.

- Internet of Things (IoT): Enabling real-time tracking and monitoring of goods throughout the supply chain.

These advancements will continue to improve supply chain efficiency and provide businesses with a competitive edge. Stay updated with the latest trends by visiting our Future Trends Section.

Conclusion

Cross-docking is an innovative and effective logistics strategy that offers significant benefits for businesses globally. By adopting cross-docking, companies can achieve reduced costs, improved efficiency, and enhanced customer satisfaction. Implementing best practices, mitigating risks, and thoroughly measuring ROI are essential steps to successfully integrate cross-docking into your supply chain operations.

Embracing cross-docking can provide your business with a competitive advantage in the marketplace, driving profitability and sustainability.