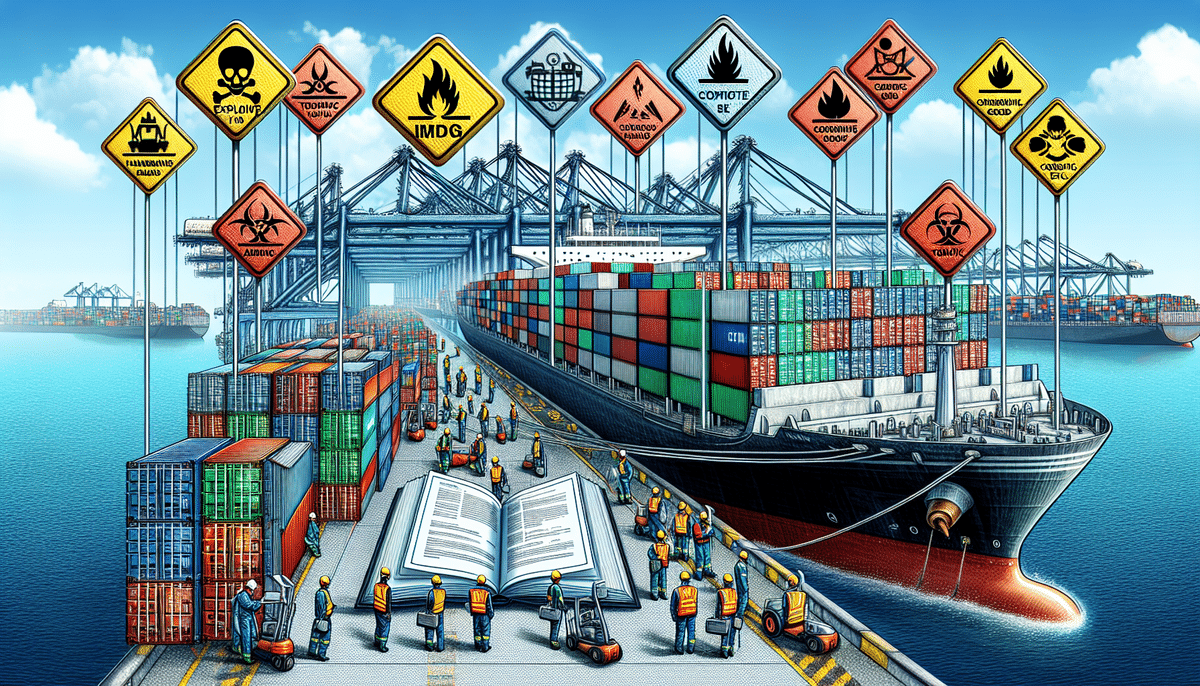

Understanding IMDG: An Introduction to International Maritime Dangerous Goods

The International Maritime Dangerous Goods (IMDG) Code is a comprehensive set of global regulations designed to ensure the safe transportation of hazardous materials by sea. Established to minimize the risk of accidents, protect the environment, and safeguard the people involved in maritime operations, IMDG compliance is mandatory for all shippers and carriers handling dangerous goods. This article provides an in-depth analysis of IMDG, highlighting its significance, the classification of dangerous goods, compliance and safety requirements, and more. Continue reading to gain a thorough understanding of IMDG and its impact on the shipping industry.

Why IMDG is Essential for the Global Shipping Industry

With international trade on the rise, the transportation of dangerous goods by sea has become increasingly prevalent. The IMDG Code plays a pivotal role in ensuring the safe and efficient movement of these materials. By providing standardized guidelines for the classification, handling, and transportation of hazardous substances, IMDG helps prevent accidents, protect the environment, and ensure the safety of maritime personnel.

Compliance with IMDG is not only a legal requirement but also a critical factor in maintaining the integrity of the global supply chain. According to the International Maritime Organization (IMO), effective implementation of IMDG reduces the likelihood of incidents that could disrupt trade and cause significant economic losses. For more detailed statistics on maritime safety, refer to the IMO's official reports.

Moreover, the IMDG Code facilitates international trade by providing a unified framework that all parties involved in the transportation process can adhere to. This standardization ensures clear communication and consistent safety measures, thereby minimizing misunderstandings and enhancing overall efficiency.

The IMDG Code is regularly updated to incorporate advancements in maritime technology and changes in the types of dangerous goods being transported. These updates ensure that the regulations remain relevant and effective in addressing new challenges in the shipping industry.

The History and Evolution of IMDG Regulations

Since its inception in 1965, the IMDG Code has undergone numerous amendments to enhance maritime safety and accommodate the evolving nature of global trade. The primary objective has always been to strike a balance between facilitating international commerce and ensuring the safe transportation of hazardous materials.

One of the significant milestones in the evolution of IMDG was the introduction of the IMDG Code Edition 1 in 1980, which standardized the classification, packaging, labeling, and documentation of dangerous goods for maritime transport. This edition laid the groundwork for future updates and established a robust framework for managing hazardous materials.

In 2003, the IMDG Code was aligned with the United Nations Recommendations on the Transport of Dangerous Goods, ensuring consistency across various modes of transportation. This alignment facilitated smoother compliance for shippers operating in multi-modal transport environments.

More recent updates have focused on emerging challenges, such as the transportation of lithium batteries and the classification of new corrosive substances. These updates are published biennially, with the latest edition incorporating the latest industry insights and regulatory requirements.

Classification of Dangerous Goods Under IMDG

The IMDG Code categorizes dangerous goods into nine distinct classes based on their inherent physical and chemical properties. This classification system is crucial for determining the appropriate handling, packaging, labeling, and transportation methods for each type of hazardous material.

- Class 1: Explosives

- Class 2: Gases

- Class 3: Flammable Liquids

- Class 4: Flammable Solids

- Class 5: Oxidizing Substances and Organic Peroxides

- Class 6: Toxic and Infectious Substances

- Class 7: Radioactive Materials

- Class 8: Corrosive Substances

- Class 9: Miscellaneous Dangerous Substances and Articles

Each class is further divided into subcategories, identified by numerical codes that provide more specific information about the nature of the hazardous material. For instance, Class 3 covers a range of flammable liquids with varying flashpoints and boiling points, each assigned a unique code to guide proper handling and storage procedures.

Understanding these classifications is essential for compliance and safety, as it ensures that each dangerous good is managed according to its specific risks and requirements.

IMDG Compliance and Safety Requirements for Shippers and Carriers

Adhering to IMDG compliance involves strict adherence to a myriad of safety requirements designed to mitigate risks associated with the transportation of hazardous materials.

- Classification: Accurate identification and classification of dangerous goods according to IMDG standards.

- Packing: Using appropriate packaging that can withstand maritime conditions and prevent leakage or contamination.

- Marking and Labeling: Clearly marking and labeling packages to convey the nature of the hazardous materials.

- Documentation: Completing necessary documentation, including Dangerous Goods Declarations and Bills of Lading.

- Training and Certification: Ensuring that all personnel involved are adequately trained and certified in IMDG regulations.

- Segregation and Stowage: Properly segregating and stowing dangerous goods to prevent reactions and ensure stability during transport.

Failure to comply with these requirements can result in severe penalties, including hefty fines, imprisonment, and the revocation of operating licenses. Additionally, non-compliance poses significant safety risks to crew members, port workers, and the surrounding environment.

To maintain compliance, shippers and carriers should implement robust internal procedures, conduct regular audits, and stay informed about the latest updates to the IMDG Code. Investing in ongoing training and certification programs for employees is also crucial in fostering a culture of safety and compliance.

The Role of Packaging, Labeling, and Marking in IMDG Compliance

Proper packaging, labeling, and marking are fundamental components of IMDG compliance. These elements ensure that dangerous goods are transported safely and that all parties involved are aware of the hazards.

Packaging: The packaging must be robust and suitable for the specific class of dangerous goods being transported. It should be tested to endure the stresses of maritime transport, including rough handling, potential spills, and exposure to varying weather conditions.

Labeling and Marking: Clear and accurate labeling is essential for communicating the nature of the hazardous materials. Labels must include appropriate hazard symbols, handling instructions, and classification codes as per IMDG guidelines. Markings should indicate the contents and provide essential information for emergency responders.

Additionally, shippers must provide comprehensive documentation, including the Dangerous Goods Declaration, which details the type, quantity, and classification of the materials being shipped. This declaration must also contain emergency response information, such as contact details for the shipper and specific procedures to follow in case of an incident.

Adhering to these packaging, labeling, and marking requirements is not only a regulatory obligation but also a critical measure for ensuring the safety of maritime operations.

IMDG Transport Documentation Requirements: Bills of Lading, Dangerous Goods Declarations, and More

Accurate and thorough documentation is a cornerstone of IMDG compliance. Several key documents must be prepared and maintained when transporting dangerous goods by sea:

- Dangerous Goods Declaration (DGD): Confirms that the goods comply with IMDG regulations and provides detailed information about the hazardous materials, including their classification, quantity, and handling instructions.

- Bill of Lading (BOL): Serves as the contract of carriage between the shipper and the carrier, outlining the terms and conditions of the shipment.

- Container Packing Certificate: Verifies that dangerous goods are properly packed and secured within the container, ensuring they meet safety standards.

- Stowage Plan: Details the precise location of hazardous materials on the vessel to prevent dangerous interactions and ensure safe stowage.

Ensuring that all required transport documents are accurately completed and readily accessible is essential for seamless operations and compliance. Incomplete or incorrect documentation can lead to shipment delays, financial penalties, and increased safety risks.

For comprehensive guidelines on IMDG documentation, refer to the Shipscience IMDG Documentation Guide.

Training and Certification Requirements for IMDG Compliance

Effective IMDG compliance hinges on the competency of the personnel involved in the transportation process. The IMDG Code mandates specific training and certification requirements for all individuals handling hazardous materials.

Training: Personnel must undergo training that covers the principles of IMDG regulations, proper handling techniques, emergency response procedures, and the specifics of the dangerous goods they are managing. This training ensures that employees are well-equipped to handle hazardous materials safely and in compliance with regulatory standards.

Certification: After completing the requisite training, individuals must obtain certification by passing an examination administered by an accredited training provider. Certification validates the individual's knowledge and ability to comply with IMDG requirements.

Regular refresher courses are also required to keep personnel updated on any changes to the IMDG Code and to reinforce best practices in hazardous material handling. Non-compliance with training and certification requirements can lead to severe legal repercussions and jeopardize the safety of maritime operations.

Common Challenges and Pitfalls in IMDG Compliance

Achieving and maintaining IMDG compliance can be challenging due to the intricate and detailed nature of the regulations. Common pitfalls include:

- Incorrect Classification: Misidentifying the class or subcategory of dangerous goods can lead to improper handling and increased risk of accidents.

- Improper Packaging: Using unsuitable packaging materials or methods can compromise the integrity of hazardous materials during transit.

- Inaccurate Documentation: Errors in transport documents can result in shipment delays, fines, and safety hazards.

- Insufficient Training: Lack of adequate training for personnel can lead to mishandling of dangerous goods and non-compliance with regulations.

To mitigate these challenges, organizations should collaborate with experienced IMDG compliance consultants, invest in comprehensive training programs, and implement rigorous internal audit processes. Staying informed about regulatory updates and continuously improving compliance strategies are also essential for overcoming these common pitfalls.

Best Practices for Safe Handling, Storage, and Transportation of Dangerous Goods Under IMDG

Adhering to best practices is crucial for ensuring the safety and compliance of dangerous goods transportation under the IMDG Code. Key best practices include:

- Comprehensive Training: Ensure all personnel are thoroughly trained and regularly updated on IMDG regulations and safety protocols.

- Proper Packaging: Utilize packaging materials and methods that meet IMDG standards for durability and safety.

- Accurate Labeling: Clearly label all dangerous goods with appropriate hazard symbols and handling instructions.

- Effective Segregation: Separate incompatible materials to prevent hazardous reactions during transport.

- Detailed Stowage Planning: Develop and adhere to a stowage plan that optimizes the safe placement of dangerous goods on the vessel.

- Regular Audits: Conduct routine compliance audits to identify and rectify potential issues proactively.

Implementing these best practices not only ensures regulatory compliance but also enhances the overall safety and efficiency of maritime operations. For more detailed guidelines, refer to the Shipscience IMDG Best Practices Guide.

Preparing for an IMDG Audit or Inspection by Regulatory Authorities

Successful navigation of an IMDG audit or inspection hinges on meticulous preparation and adherence to regulatory standards. Here are essential steps to prepare effectively:

- Comprehensive Documentation: Ensure all required documents, including Dangerous Goods Declarations, Bills of Lading, and Packing Certificates, are complete, accurate, and readily accessible.

- Staff Training: Verify that all personnel involved in handling dangerous goods are fully trained and possess the necessary certifications.

- Internal Audits: Conduct regular internal audits to assess compliance with IMDG regulations and identify areas for improvement.

- Stowage Plans: Maintain up-to-date stowage plans that clearly outline the placement of hazardous materials on vessels.

- Emergency Procedures: Develop and communicate robust emergency response procedures to handle potential incidents effectively.

By proactively addressing these areas, organizations can ensure they are well-prepared for audits and inspections, thereby minimizing the risk of non-compliance penalties and enhancing overall safety.

Recent Updates and Amendments to the IMDG Code: What Shippers and Carriers Need to Know

The IMDG Code undergoes biennial updates to incorporate new safety measures, address emerging risks, and reflect changes in the maritime industry. Recent amendments include:

- Lithium Batteries: Enhanced guidelines for the packaging, labeling, and transportation of lithium batteries to mitigate fire and explosion risks.

- Corrosive Substances: Revised classification criteria for corrosive substances to ensure accurate identification and handling.

- Environmental Protection: Updated regulations to better protect marine environments from potential contamination caused by hazardous materials.

- Technology Integration: Incorporation of digital documentation and tracking systems to streamline compliance processes.

Staying informed about these updates is essential for shippers and carriers to maintain compliance and adopt best practices. For detailed information on the latest IMDG amendments, visit the Shipscience IMDG Updates Page.

Understanding the Liability Implications of Non-Compliance with IMDG Regulations

Non-compliance with IMDG regulations carries significant liability implications that can have far-reaching consequences for organizations involved in maritime transport. These include:

- Financial Penalties: Fines imposed by regulatory authorities for violations can be substantial, impacting the financial stability of a company.

- Legal Action: Severe breaches can lead to lawsuits, resulting in legal costs and potential damages awards.

- Reputational Damage: Incidents resulting from non-compliance can tarnish a company's reputation, leading to loss of business and diminished trust among stakeholders.

- Operational Disruptions: Non-compliance can result in shipment delays, detentions, and the revocation of operating licenses, disrupting business operations.

- Environmental and Safety Hazards: Improper handling of dangerous goods can cause environmental pollution, injuries, or fatalities, leading to humanitarian and ecological crises.

To mitigate these risks, organizations must prioritize IMDG compliance through robust training, accurate documentation, and ongoing monitoring of regulatory changes.

Expert Tips and Advice on Navigating the Complexities of IMDG Compliance

Successfully navigating IMDG compliance requires a strategic approach and the utilization of expert resources. Here are some valuable tips:

- Engage Compliance Experts: Collaborate with experienced IMDG consultants who can provide tailored guidance and support.

- Invest in Training: Ensure continuous training and certification programs for all personnel involved in handling dangerous goods.

- Leverage Technology: Utilize compliance management software to streamline documentation, track regulatory updates, and monitor compliance status.

- Conduct Regular Audits: Perform internal audits to identify compliance gaps and implement corrective actions promptly.

- Stay Informed: Keep abreast of the latest IMDG updates and industry best practices through reputable sources and professional networks.

By adopting these practices, organizations can effectively manage the complexities of IMDG compliance, ensuring safe and efficient transportation of hazardous materials.

Conclusion

The IMDG Code is a vital framework that underpins the safe transportation of dangerous goods by sea. Understanding and adhering to its regulations is essential for shippers and carriers to ensure compliance, safeguard lives, and protect the environment. By staying informed about regulatory changes, investing in comprehensive training, and implementing best practices, organizations can navigate the complexities of IMDG compliance with confidence and efficiency.