Achieving OTIF (On-Time In-Full) Delivery: Strategies for Success

In today's business world, on-time delivery is a critical factor for customer satisfaction. Delivering products on time and in full not only enhances customer satisfaction but also helps build trust and strengthens brand loyalty. Achieving on-time in-full delivery (OTIF) requires a comprehensive approach emphasizing reliability, efficiency, and flexibility throughout your supply chain. In this article, we'll explore various strategies that can help businesses achieve OTIF delivery success.

Understanding the Importance of OTIF Delivery

OTIF delivery is the ultimate benchmark for supply chain performance. It refers to delivering products on or before the scheduled delivery date in the correct quantity and quality. Achieving this translates to accurately meeting customer expectations. In today's demanding market, there's little room for error when it comes to delivering goods. Delayed deliveries, damaged goods, or incomplete orders can lead to significant losses, reduced trust, and customers switching to competitors.

Key benefits of achieving OTIF delivery include:

- Positive Reputation: Customers receiving orders on time and in good condition are more likely to recommend your business to others, leading to increased sales and revenue.

- Streamlined Supply Chain: OTIF delivery helps reduce costs and improve efficiency by optimizing supply chain processes.

However, achieving OTIF delivery can be challenging, especially for businesses with complex supply chains. Investing in the right technology and tools, such as advanced analytics and automated inventory management systems, is crucial. By taking a proactive approach to supply chain management, you can improve your chances of achieving OTIF delivery and staying ahead of the competition.

The Impact of Late or Incomplete Deliveries on Your Business

Late or incomplete deliveries can have extensive associated costs, including:

- Lost Sales: Incomplete orders can result in immediate revenue loss.

- Low Customer Satisfaction: Dissatisfied customers are less likely to return.

- Increased Overhead Costs: Handling returns and addressing complaints can drive up costs.

- Penalties: Production problems and failure to meet contractual obligations can lead to fines.

- Reduced Market Share: Competitors may attract your dissatisfied customers.

Moreover, late or incomplete deliveries can damage a company's reputation and brand image, making the business appear unreliable and untrustworthy. This can lead to a loss of customer loyalty and potential future sales. Delays can also disrupt production processes, decreasing efficiency and increasing costs. Therefore, prioritizing timely and complete deliveries is essential to maintain a positive reputation and ensure smooth operations.

Key Performance Indicators (KPIs) for Measuring OTIF Delivery

Effective OTIF delivery requires tracking and measuring several key performance indicators (KPIs). These include:

- On-Time Delivery Rate: The percentage of orders delivered on or before the promised date.

- Order Completion Rate: The percentage of orders fulfilled entirely without any missing items.

- Quality Fulfillment Rate: The percentage of orders delivered without quality issues.

- Delivery Accuracy: The correctness of order details, including quantity and specifications.

- Average Lead Time: The average time taken from order placement to delivery.

These KPIs help identify problem areas and provide data for decision-making to improve the OTIF score with a rational approach. For instance, a high on-time delivery rate indicates that the company meets customer expectations, while a low rate can lead to dissatisfied customers and lost business.

Another critical KPI is the delivery accuracy rate, which measures the percentage of orders delivered without errors or discrepancies. High delivery accuracy reduces returns and customer complaints, whereas low accuracy can increase costs and harm the company's reputation.

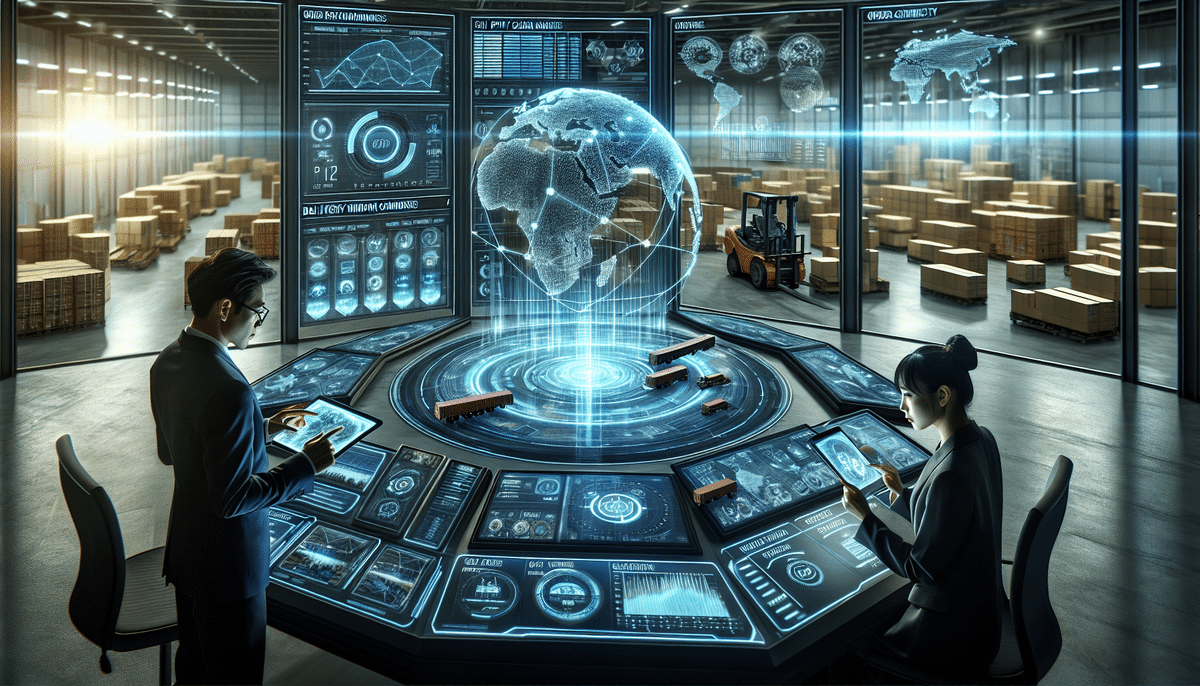

Analyzing and Evaluating Your Supply Chain for OTIF Success

Achieving OTIF delivery success involves thoroughly evaluating and analyzing different elements of your supply chain. Conducting a comprehensive risk assessment of individual procedures and assessing interdependent processes can help identify areas that require adjustments. Continuous performance reviews and establishing an effective OTIF management structure can have a positive impact.

Key steps include:

- Stakeholder Alignment: Ensure all stakeholders, including suppliers, manufacturers, distributors, and retailers, are aligned with the same goals and objectives.

- Clear Communication: Establish transparent communication channels and set clear expectations to ensure everyone works towards achieving OTIF delivery.

- Technology and Data Analytics: Utilize technology to gain real-time visibility into your supply chain, identify bottlenecks, and make data-driven decisions to optimize operations.

By leveraging technology and fostering collaboration among stakeholders, businesses can enhance their supply chain efficiency and improve OTIF delivery performance.

Building Strong Relationships with Suppliers to Improve Delivery Reliability

Building strong relationships with suppliers is vital to ensuring OTIF delivery. This involves:

- Frequent Communication: Maintain regular contact to discuss expectations and address any issues promptly.

- Joint Forecasting: Collaborate with suppliers to predict demand accurately and plan accordingly.

- Clear Agreements: Establish clear agreements on quality specifications and delivery timelines.

A solid bond with trusted suppliers who understand and support your business is a guarantee for success. Integration with suppliers can include inventory management, supplier quality standards, delivery schedules, and maintaining sufficient communication to ensure accurate order fulfillment.

Additionally, establishing performance metrics with suppliers—such as tracking delivery times, quality of goods received, and responsiveness—can identify areas for improvement and foster collaborative problem-solving. Prioritizing the long-term sustainability of supplier relationships by encouraging sustainable practices also enhances your reputation and contributes to a more sustainable global economy.

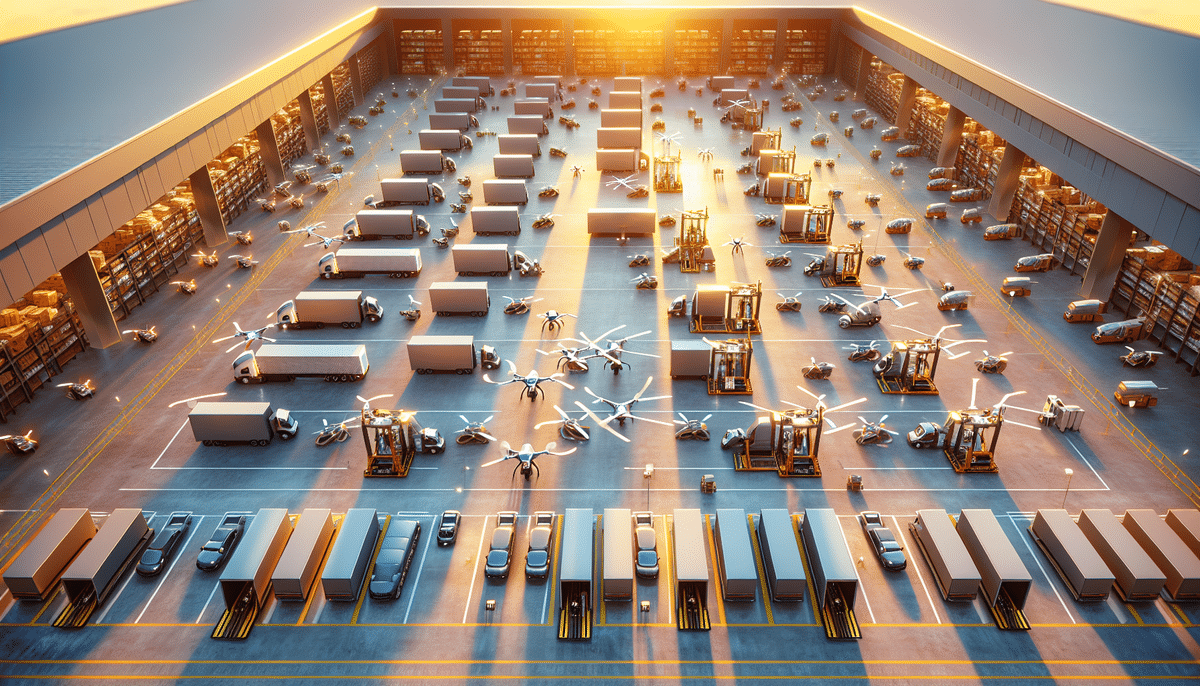

Implementing Technology Solutions to Enhance OTIF Delivery

Many businesses leverage technology solutions to enhance OTIF delivery. These solutions include:

- Real-Time Tracking Systems: Monitor shipments in real-time to ensure timely delivery.

- Automated Distribution Centers: Streamline operations and reduce human error.

- Barcoding: Improve inventory management and order accuracy.

- Advanced Data Analysis: Utilize data analytics to identify trends and optimize processes.

- Internet of Things (IoT) Applications: Enhance connectivity and monitor various aspects of the supply chain.

Implementing a robust Transportation Management System (TMS) coupled with advanced analytics can significantly contribute to achieving OTIF delivery. Benefits of technology implementation include:

- Route Optimization: Identify the most efficient routes to reduce transportation costs and delivery times.

- Bottleneck Identification: Detect and address inefficiencies proactively.

- Cost Reduction: Lower fuel consumption and minimize delivery expenses.

- Increased Transparency: Enhance visibility across the supply chain, leading to better decision-making.

By leveraging these technology solutions, businesses can not only improve their OTIF delivery performance but also reduce costs and increase customer satisfaction.

Creating a Culture of Accountability for On-Time Delivery

Developing a culture of accountability within the organization emphasizes meeting delivery targets and proactively addressing supply chain issues. This culture ensures that:

- Clear Roles: Employees understand their individual responsibilities in achieving OTIF delivery.

- Interdepartmental Collaboration: Promotes interaction among departments to solve challenges effectively.

- Proactive Problem-Solving: Encourages addressing issues that may impact OTIF delivery targets swiftly.

A culture of accountability drives employees to take ownership of their tasks, leading to more efficient resolution of issues that could hinder timely deliveries and minimize losses.

Utilizing Lean Principles for Efficient and Effective Supply Chain Operations

Lean principles aim to eliminate wasteful practices and allocate resources productively, optimizing the supply chain to ensure OTIF deliveries. Key aspects include:

- Maximizing Production Efficiency: Streamline processes to enhance productivity.

- Optimizing Inventory Levels: Maintain optimal stock levels to meet demand without overstocking.

- Minimizing Lead Times: Reduce the time from order placement to delivery.

- Reducing Cycle Time: Shorten the time required to complete each step in the supply chain.

- Streamlining Operations: Simplify processes to enhance overall efficiency.

Implementing these principles leads to more streamlined and cost-effective operations, resulting in seamless OTIF delivery. By continuously refining supply chain processes through lean methodologies, businesses can achieve sustained OTIF delivery performance.

How to Forecast Demand Accurately to Improve OTIF Delivery

Accurately forecasting demand significantly impacts OTIF delivery. Effective forecasting techniques include:

- Collecting and analyzing historical data to identify trends.

- Forecasting new product launches by anticipating market reception.

- Accounting for seasonal demands to adjust inventory levels accordingly.

Incorporating advanced demand forecasting solutions with artificial intelligence (AI) and machine learning (ML) can enhance prediction accuracy by considering various factors that impact demand. Regularly updating forecasts improves inventory planning, ensuring the delivery of the right product in the correct quantity at the right time to meet customer expectations.

Strategies for Managing Unexpected Disruptions in the Supply Chain

Unexpected disruptions are inevitable in complex supply chains. Businesses can prepare for such events through effective risk management strategies, which involve:

- Defining Risk Events: Identify potential disruptions that could impact the supply chain.

- Analyzing Risks: Assess the likelihood and impact of each risk event.

- Identifying Trigger Points: Determine indicators that signal the onset of a disruption.

- Root Cause Analysis: Investigate the underlying causes of disruptions to prevent recurrence.

- Contingency Planning: Develop backup plans to maintain operations during disruptions.

- Buffering Stock: Maintain safety stock to cushion against supply chain interruptions.

By preparing accurate strategies in advance, businesses can minimize losses and reduce OTIF failures during unforeseen disruptions.

Communicating Effectively with Customers to Ensure On-Time Delivery Expectations are Met

Effective communication with customers about their orders is crucial for maintaining satisfaction and trust. Strategies include:

- Order Status Updates: Provide regular updates on the progress of orders through calls, emails, text messages, or automated notifications.

- Transparency: Inform customers promptly about any delays or changes in delivery timelines.

- Proactive Modifications: Adjust delivery schedules or product quality standards in advance to accommodate unforeseen changes.

Maintaining continuous engagement and transparency helps customers plan effectively and appreciate the effort taken to communicate any changes, thereby enhancing overall customer satisfaction.

Best Practices for Continuous Improvement in OTIF Delivery Performance

Improving OTIF delivery performance is an ongoing process that requires:

- Regular Evaluation: Continuously assess KPIs and adjust strategies accordingly.

- Optimized Inventory Management: Ensure inventory levels align with demand forecasts.

- Elimination of Waste: Identify and remove inefficiencies in supply chain processes.

- Leveraging Technology: Utilize technology-supported solutions to enhance supply chain operations.

- Data-Driven Decisions: Make informed decisions based on performance data and analytics.

- Culture of Accountability: Foster a work environment where employees are responsible for their roles in achieving OTIF delivery.

By monitoring and tracking performance regularly and making data-driven decisions, businesses can refine processes, reduce risks, and contribute to the overall success of their supply chain. A culture of accountability further drives continuous improvement across all supply chain processes.

Conclusion

OTIF delivery is a crucial benchmark for supply chain performance and customer satisfaction. Achieving it requires a comprehensive approach that emphasizes reliability, efficiency, and flexibility throughout the supply chain. Evaluating and analyzing various elements in the supply chain, building strong relationships with suppliers, leveraging technology solutions, fostering a culture of accountability, implementing efficient demand forecasting, and continuous performance review are essential strategies for OTIF delivery success.