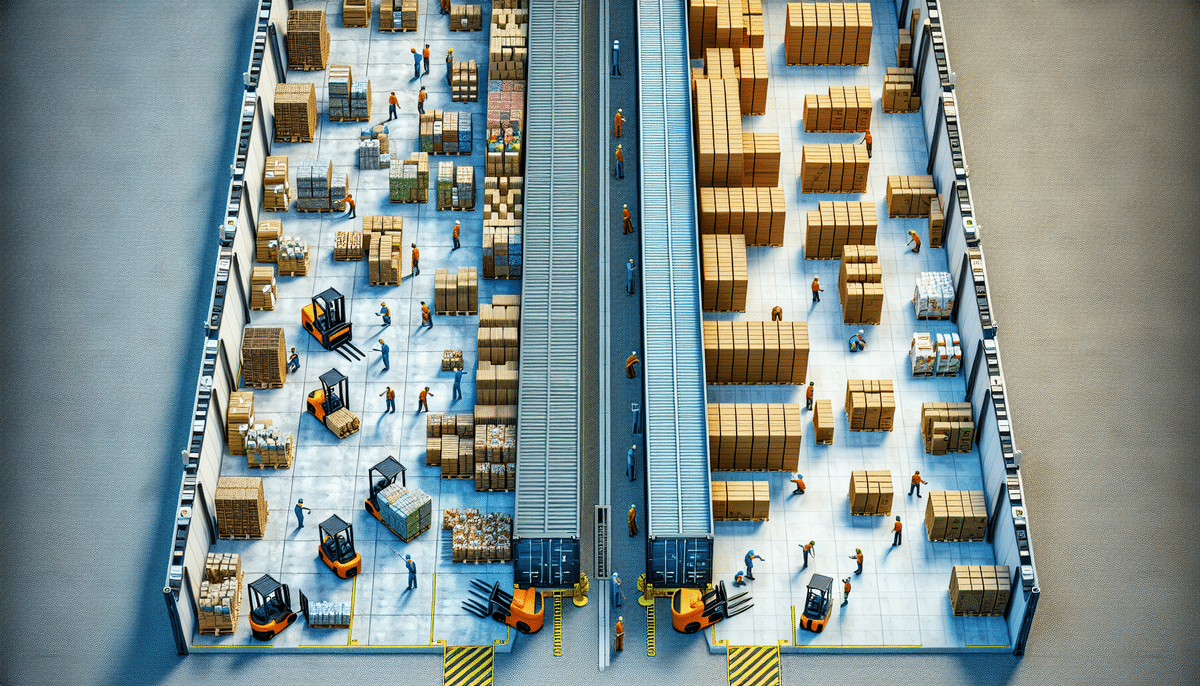

Comparing Floor Loaded and Palletized Shipping Containers

When it comes to shipping goods, the two most popular methods are floor loaded and palletized shipping containers. Each method has its own unique set of advantages and disadvantages, making it important for businesses to understand which method is best for their needs. In this article, we will outline the basics of floor loaded and palletized shipping containers, their pros and cons, safety considerations, and much more. So let’s dive in and compare floor loaded and palletized shipping containers.

Understanding the Basics of Floor Loaded and Palletized Shipping Containers

Floor loading is the process of loading goods directly onto the floor of the container. This method is typically used when large or odd-shaped items are being shipped. Palletized shipping, on the other hand, involves the goods being placed on pallets and then loaded into the container. Pallets are a standard size and shape, which makes them easier to stack and transport. They also protect goods from damage during shipping and simplify loading and unloading.

When choosing between floor loaded and palletized shipping containers, several factors must be considered. Floor loading may be more cost-effective for certain types of goods, but it can also be more time-consuming and require more labor. Palletized shipping, on the other hand, may be more efficient and easier to manage, but it can also be more expensive due to the cost of pallets and additional handling equipment.

Another important consideration is the type of goods being shipped. Fragile or high-value items may require extra protection, which can be provided by pallets and other packaging materials. Additionally, some shipping companies may have specific requirements or restrictions on the use of floor loaded or palletized containers, depending on the destination and mode of transportation.

For more detailed information on shipping container types, refer to the ShipScience shipping container guide.

Pros and Cons of Floor Loaded Shipping Containers

One advantage of floor loaded containers is that they can accommodate larger items or products of unusual shapes. Additionally, since there are no pallets or other loading equipment required, floor loading is generally quicker and less expensive than palletized shipping. However, one of the main disadvantages of floor loading is the lack of protection for the goods being shipped.

Another disadvantage of floor loading is the increased risk of damage to the goods during transportation. Without the added support of pallets or other loading equipment, the items inside the container are more likely to shift or topple over, causing damage. This risk is especially high for fragile or delicate items.

On the other hand, floor loading can be a more efficient use of space within the container, as there is no need to leave room for pallets or other loading equipment. This can be particularly beneficial for companies shipping large quantities of goods, as it allows them to maximize the amount of product they can fit into each container.

According to the 2023 Shipping Statistics Report, floor loading can reduce container space wastage by up to 15% compared to palletized loading.

Advantages and Disadvantages of Palletized Shipping Containers

Palletized shipping containers offer better protection for goods and simplify the loading and unloading process, making it faster and more efficient. Pallets also make stacking easier and more organized, saving space and reducing damage to the contents of the container. One of the main disadvantages of palletized shipping is the need for additional equipment, such as forklifts or pallet jacks, which can add additional costs.

Another advantage of palletized shipping containers is that they can be easily tracked and monitored during transportation. Each pallet can be labeled with a unique identifier, allowing for easy tracking of inventory and ensuring that all items are accounted for. This can be especially useful for businesses that deal with high-value or sensitive goods.

However, one of the biggest disadvantages of palletized shipping is the potential for pallets to become damaged or lost during transportation. If a pallet is damaged, it can compromise the safety of the goods inside and lead to additional costs for the business. Additionally, if a pallet is lost or misplaced, it can cause delays in delivery and result in dissatisfied customers.

For an in-depth analysis of palletized shipping benefits, see the ShipScience palletized shipping resources.

Why Use Floor Loaded Shipping Containers?

Floor loaded shipping containers are ideal for shipping items that are too large to fit on a standard pallet. This method is also useful for fragile goods that need to be packed tightly to avoid damage during shipping. Additionally, floor loaded containers can help reduce shipping costs if the contents of the container require less space than if they had been palletized.

Another advantage of using floor loaded shipping containers is that they can be loaded and unloaded quickly, which can save time and increase efficiency. This is because there is no need to spend time and resources on palletizing and de-palletizing the goods. Instead, the items can be loaded directly onto the container floor, and then unloaded in the same way at the destination.

Furthermore, floor loaded containers can be a more secure option for shipping valuable or sensitive items. Since the goods are packed tightly and directly on the container floor, there is less risk of them shifting or becoming damaged during transit. This can provide peace of mind for both the shipper and the recipient, knowing that the items will arrive at their destination in the same condition as when they were loaded.

Benefits of Using Palletized Shipping Containers

Palletized containers offer better protection for goods, easier loading and unloading, and more space-efficient storage. Palletized shipping also reduces the risk of damage during transit and lowers the chances of accidents in the warehouse or during shipping. Furthermore, pallets are universally used, allowing for smoother integration into the supply chain.

In addition to the benefits mentioned above, palletized shipping containers also offer environmental advantages. By using pallets, companies can reduce the amount of packaging materials needed for shipping, which in turn reduces waste and lowers carbon emissions. Pallets are also reusable and recyclable, making them a sustainable option for businesses.

Another advantage of using palletized shipping containers is that they can help streamline logistics and improve efficiency. Pallets can be easily tracked and managed, allowing for better inventory control and faster turnaround times. This can lead to cost savings for businesses and a more reliable supply chain for customers.

According to the Environmental Science Institute, pallet recycling can reduce environmental impact by up to 30% compared to single-use packaging solutions.

The Cost Comparison: Floor Loaded vs Palletized Shipping Containers

The cost per unit of a floor loaded container is generally lower due to the reduced need for labor and equipment. However, the upfront costs of pallets and pallet-related equipment can increase the cost of palletized shipping. In general, businesses should choose the method that best suits their specific shipping needs and budget.

It is important to note that while floor loaded containers may have a lower cost per unit, they may not be the best option for all types of cargo. For example, fragile or irregularly shaped items may require the additional support and stability provided by pallets. Additionally, palletized shipping can often be more efficient in terms of loading and unloading times, which can ultimately save businesses money in the long run. Ultimately, the decision between floor loaded and palletized shipping should be based on the specific needs of the cargo and the budget of the business.

For a detailed cost analysis, refer to the ShipScience cost comparison tool.

Safety Considerations for Floor Loaded and Palletized Shipping Containers

When it comes to safety, both floor loaded and palletized shipping containers have their own unique considerations. Floor loading can be dangerous if appropriate safety measures are not taken, such as not securing the cargo or overloading the container. Palletized shipping can also be dangerous if the cargo is not evenly distributed or if the pallets are stacked too high. To ensure safety, businesses should follow industry best practices and guidelines, such as proper cargo securement and proper loading techniques.

Refer to the OSHA Shipping Safety Guidelines for comprehensive safety protocols.

How to Pack a Floor Loaded Container Safely and Efficiently

Here are some tips to pack a floor loaded container safely and efficiently:

- Ensure the cargo is properly secured and not overloaded

- Pack heavier items on the bottom to prevent them from crushing lighter items

- Fill any gaps with stowage material

- Label boxes and items properly for easy identification

Best Practices for Loading and Unloading Palletized Containers

Here are some best practices for loading and unloading palletized containers:

- Choose the right type of pallet for your products

- Ensure that the pallets and cargo are properly labeled

- Stack pallets square and straight to prevent them from falling over

- Do not exceed the weight capacity of the pallets or the container

Tips for Choosing the Right Shipping Container for Your Business Needs

When choosing a shipping container, factors to consider include the type of goods being shipped, the destination, the mode of transport, and the budget. Floor loading is ideal for oversized items, while palletized containers are better suited for standard-sized items. The destination will also play a role in deciding whether floor loading or palletized shipping is more appropriate. By taking the time to assess these factors, businesses can choose the best container for their specific needs.

Use tools like the ShipScience Shipping Container Selector to make informed decisions.

Common Mistakes to Avoid When Using Floor Loaded or Palletized Containers

Common mistakes to avoid when using floor loaded or palletized containers include:

- Overloading the container

- Using the wrong size pallets

- Improperly securing the cargo

- Stacking pallets too high

Taking the time to carefully plan and execute the loading and unloading process can help prevent these mistakes and reduce the risk of damage or injury.

Future Trends in the Shipping Industry: Impact on Floor Loaded vs Palletized Containers

The shipping industry is continually evolving, with advancements in technology, sustainability, and e-commerce shaping the future of the industry. However, floor loaded and palletized containers are likely to remain relevant for some time. The growing trend towards sustainable shipping may shift the balance towards palletized containers due to their ability to be reused and recycled. Emerging technologies may also improve safety and efficiency, making both methods more appealing.

According to the McKinsey Future of Shipping Report, automation and smart technologies are expected to drive significant changes in container shipping practices by 2025.

Case Studies: Success Stories of Companies That Used Floor Loaded or Palletized Containers

For companies looking to improve their shipping processes, case studies can offer insights and inspiration. One success story is Apple, which uses floor loaded containers to ship large and delicate products such as iMacs and MacBooks. Another success story is Nestlé, which uses palletized containers to efficiently transport their products while reducing waste and increasing sustainability. These success stories demonstrate the value of choosing the right shipping method for your unique needs and the potential benefits of implementing a new approach.

Learn more about these case studies in the ShipScience Case Studies.

Conclusion: Which Type of Container Is Best for Your Business?

As we’ve seen, choosing between floor loaded and palletized shipping containers depends on a variety of factors such as the type of goods being shipped, destination, budget, and more. By carefully assessing these factors, businesses can determine which method is best for their specific needs. Ultimately, the choice between floor loaded and palletized shipping comes down to the unique needs of your business and the products you are shipping.

For personalized advice, consult with shipping experts at ShipScience.