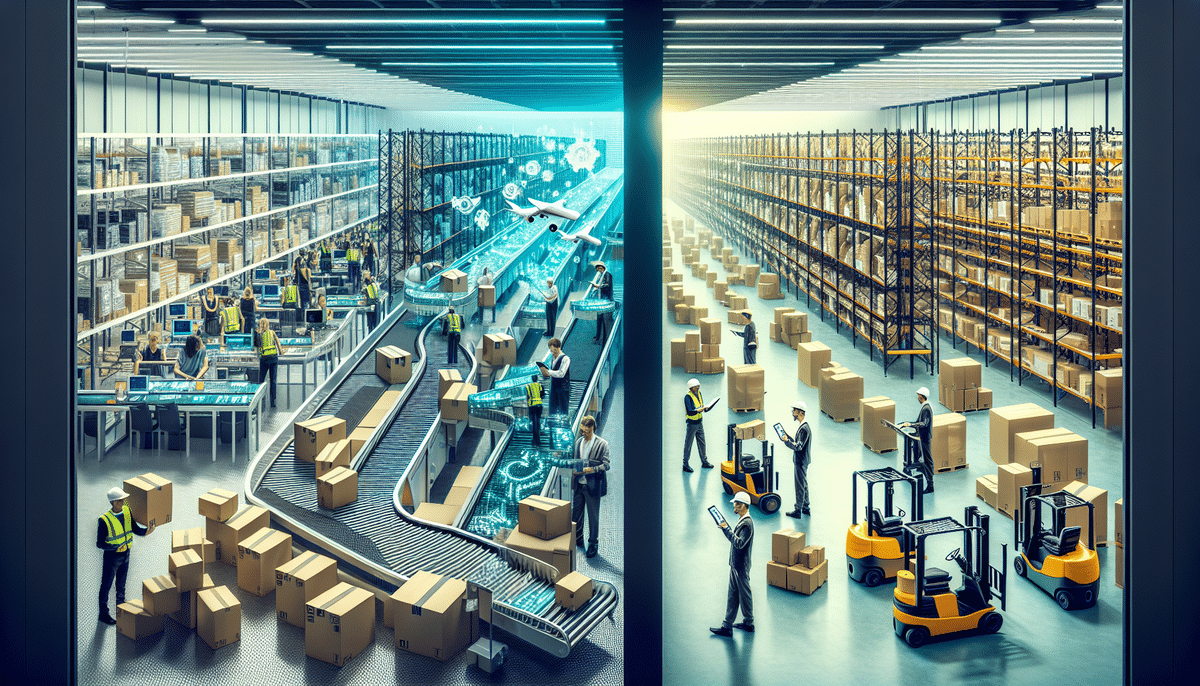

Comparing a Fulfillment Center to a Warehouse: What's the Difference?

When it comes to storing and fulfilling products, businesses have a multitude of options. Two common choices are using a fulfillment center or a warehouse. While they may seem similar, there are distinct differences between the two. In this article, we'll delve into those differences, supported by recent data and industry insights, to help you determine which option is best suited for your business needs.

Understanding the Basics: What is a Fulfillment Center?

A fulfillment center is a specialized facility that stores products and processes orders on behalf of another company. Typically owned and operated by third-party logistics (3PL) providers, fulfillment centers excel in managing inventory and handling shipping logistics. Equipped with advanced technology and automation tools, these centers efficiently manage large volumes of orders, ensuring quick and accurate delivery to customers.

In addition to inventory management and shipping, fulfillment centers offer value-added services such as kitting, assembly, and customization. Kitting involves bundling multiple products into a single package, while assembly refers to putting together individual components to create finished products. Customization includes personalizing products with unique branding or packaging. These services allow businesses to outsource time-consuming tasks, ultimately saving time and reducing operational costs.

According to a Forbes report, the global third-party logistics market is expected to reach $12.68 billion by 2026, indicating the growing reliance on fulfillment centers for efficient order processing and delivery.

Understanding the Basics: What is a Warehouse?

A warehouse is a facility designed primarily for the long-term storage of products or materials. Unlike fulfillment centers, warehouses are generally used to store bulk quantities of goods until they are needed by customers or other parts of the supply chain. Commonly utilized by manufacturers, wholesalers, and retailers, warehouses provide the necessary space to manage inventory over extended periods.

Warehouses vary in size and design based on the types of products stored and the specific needs of the business. Some are small and simple, while others are expansive and feature multiple levels, climate control, and specialized equipment for handling and moving goods. Modern warehouses often incorporate automation and inventory management systems to enhance efficiency and accuracy.

Beyond storage, many warehouses offer additional services such as inventory management, order fulfillment, and shipping and receiving. Some also provide value-added services like product assembly, packaging, and labeling, which help businesses streamline operations and reduce costs.

The Key Differences Between Fulfillment Centers and Warehouses

The primary distinction between fulfillment centers and warehouses lies in their intended purpose. Fulfillment centers are optimized for processing and fulfilling individual customer orders, whereas warehouses focus on the long-term storage of bulk quantities of products. Fulfillment centers are often operated by 3PL providers, leveraging their expertise and infrastructure, while warehouses may be owned and managed internally by individual companies.

Another significant difference is location strategy. Fulfillment centers are strategically positioned near major population centers to facilitate faster delivery times, enhancing customer satisfaction. In contrast, warehouses might be located further away from dense population areas due to their focus on bulk storage rather than rapid distribution.

Furthermore, fulfillment centers typically employ more sophisticated technology and employ specialized staff to handle order processing efficiently. They may also offer additional services such as gift wrapping, personalized notes, and returns processing—services not usually provided by traditional warehouses.

What Kind of Businesses Use Fulfillment Centers?

Fulfillment centers are predominantly utilized by e-commerce businesses and companies that sell products online. These businesses often lack the resources or expertise to manage their own inventory and shipping operations, making 3PL partnerships an attractive solution for enhancing efficiency.

In addition to e-commerce, fulfillment centers are also favored by subscription box companies, direct-to-consumer brands, and businesses that offer same-day or next-day delivery services. These companies depend on fulfillment centers to swiftly and accurately process orders, manage inventory, and handle shipping logistics. By outsourcing these tasks, they can concentrate on core business activities such as marketing and product development.

According to a 2023 report by Statista, the adoption of 3PL services among e-commerce businesses has increased by 15% over the past year, highlighting the growing trend and reliance on fulfillment centers to handle logistics effectively.

What Kind of Businesses Use Warehouses?

Warehouses serve a diverse range of businesses, including manufacturers, wholesalers, retailers, and even sectors like the entertainment industry. Any business that requires the storage of bulk quantities of products for extended periods can benefit from using a warehouse.

E-commerce companies, despite often using fulfillment centers, also rely on warehouses to store large inventories and manage stock levels efficiently. With the surge in online shopping, having a robust warehousing solution is critical for handling the high volume of products and ensuring timely order fulfillment.

Moreover, industries such as entertainment use warehouses to store props, costumes, and sets between productions, allowing for easy access and reuse in subsequent projects. This utilization underscores the versatility of warehouses in supporting various business needs.

The Advantages of Using a Fulfillment Center for Your Business

Employing a fulfillment center offers several benefits, including:

- Access to Advanced Technology: Fulfillment centers utilize state-of-the-art software and automation tools for order processing and inventory management.

- Cost Efficiency: Outsourcing fulfillment operations can reduce overhead costs associated with managing a dedicated warehouse and staffing.

- Enhanced Efficiency: With streamlined processes, fulfillment centers can achieve faster order fulfillment times, improving customer satisfaction.

- Scalability: Fulfillment centers can easily handle fluctuations in order volume, allowing businesses to scale operations without significant investments.

Additionally, fulfillment centers offer flexibility in shipping options by partnering with multiple carriers. This allows businesses to choose the most cost-effective and efficient shipping methods, resulting in cost savings and expedited delivery times.

Data from the Investopedia indicates that businesses utilizing fulfillment centers experience a 20% reduction in shipping times on average, leading to higher customer satisfaction rates.

The Advantages of Using a Warehouse for Your Business

Choosing to use a warehouse presents several advantages, including:

- Long-Term Storage: Warehouses are ideal for storing large quantities of products over extended periods.

- Inventory Control: Businesses have greater oversight and control over inventory management and security.

- Customization: Warehouses can tailor storage and handling solutions to meet specific business requirements.

Moreover, centralizing inventory in a single location through a warehouse can streamline business operations, reducing the time and resources spent on managing multiple storage sites. This consolidation leads to increased operational efficiency and cost savings.

A study by Warehouse Standard found that businesses using dedicated warehouses experienced a 25% increase in inventory accuracy, contributing to more reliable stock levels and reduced instances of overstocking or stockouts.

How to Determine Which is Best for Your Business: A Fulfillment Center or a Warehouse

Choosing between a fulfillment center and a warehouse hinges on your business's specific needs and objectives. Key factors to consider include:

- Order Volume: High order volumes may benefit more from the streamlined processes of fulfillment centers.

- Product Type and Size: Consider the nature of your products; bulky or specialty items might be better suited for warehousing.

- Budget: Assess your financial resources for storage and fulfillment operations.

- Automation Needs: If your business requires high levels of automation, fulfillment centers are typically better equipped.

For tailored advice, consulting with a logistics professional can provide valuable insights based on your business's unique circumstances.

Additionally, reviewing industry benchmarks and performance metrics can guide your decision. According to a Logistics Management report, businesses that carefully align their storage solutions with their operational goals see a 30% improvement in supply chain efficiency.

The Costs Involved in Using a Fulfillment Center vs a Warehouse

Both fulfillment centers and warehouses incur costs related to storage and handling, but the cost structures differ:

- Fulfillment Centers: Typically charge based on per-unit storage, order picking, and shipping. Additional services like gift wrapping or returns processing may incur extra fees.

- Warehouses: May involve rent or lease fees, pallet handling fees, and costs for labor, maintenance, and equipment. Initial investments in infrastructure and handling equipment can also be significant.

Fulfillment centers often provide comprehensive packages that include various services, simplifying budgeting and cost management. In contrast, warehouses may require more detailed financial planning to account for diverse expenses.

Research from Business News Daily highlights that while fulfillment centers can reduce operational overhead by up to 40%, warehouses may demand higher upfront investments but offer more control over long-term storage solutions.

Considerations When Choosing Between a Fulfillment Center and a Warehouse

When deciding between a fulfillment center and a warehouse, consider the following:

- The type and size of products you sell

- The volume of orders you receive

- Your budget for storage and fulfillment

- Your need for control over inventory management and shipping

- Your desire for scalability and flexibility

Location is another critical factor. If your customer base is concentrated in a specific region, selecting a fulfillment center nearby can reduce shipping costs and delivery times. Conversely, if your products are bulky or heavy, positioning a warehouse closer to suppliers can minimize transportation expenses.

Moreover, consider the level of customer service you aim to provide. Fulfillment centers can offer personalized services like gift wrapping, which enhance the customer experience, whereas warehouses focus primarily on storage and distribution.

According to a Supply Chain Dive study, businesses that strategically align their storage solutions with customer demographics experience a 15% increase in customer retention rates.

Understanding the Importance of Location for Your Fulfillment Center or Warehouse

The location of your fulfillment center or warehouse significantly impacts shipping costs and order fulfillment times. Key considerations include:

- Proximity to Target Markets: Being closer to major customer bases can decrease delivery times and shipping costs.

- Access to Transportation Hubs: Proximity to airports, seaports, and major highways facilitates efficient logistics and distribution.

- Labor Availability: Locations with a robust labor pool can ensure that your fulfillment or warehousing operations are adequately staffed.

- Local Regulations and Taxes: Different regions have varying regulations and tax implications that can affect operational costs.

For instance, selecting a location in a state with favorable tax policies can result in substantial cost savings. It's essential to research and understand local regulations and economic conditions before finalizing a location.

A report by Geopointe emphasizes that location strategy can influence overall supply chain performance by up to 20%, highlighting the critical nature of this decision.

Managing Inventory in a Fulfillment Center vs a Warehouse

Inventory management practices differ significantly between fulfillment centers and warehouses due to their distinct operational focuses:

- Fulfillment Centers: Utilize advanced software and real-time tracking systems to monitor individual units for precise order processing. Automation and integration with e-commerce platforms enhance accuracy and efficiency.

- Warehouses: Often employ simpler methods such as manual inventory counts, barcode scanning, and periodic audits. While effective for bulk storage, these methods may lack the real-time precision of fulfillment centers.

Effective inventory management is crucial for minimizing stockouts and overstock situations. Leveraging technologies like RFID tagging and inventory management software can enhance accuracy and streamline operations in both settings.

According to a Investopedia article, businesses that implement advanced inventory management systems can reduce inventory costs by up to 30% while improving order accuracy and customer satisfaction.

Common Mistakes to Avoid When Using a Fulfillment Center or Warehouse

Avoiding common pitfalls is essential for optimizing your storage and fulfillment operations. Common mistakes include:

- Inadequate Vetting: Failing to properly evaluate your 3PL partner or warehouse provider can lead to inefficiencies and service disruptions.

- Poor Inventory Forecasting: Inaccurately predicting inventory needs can result in overstocking or stockouts, affecting sales and customer satisfaction.

- Improper Labeling or Organization: Disorganized products can slow down handling and increase the risk of errors in order fulfillment.

- Lack of Inventory Tracking: Not maintaining accurate records of inventory levels and locations can lead to discrepancies and operational inefficiencies.

To mitigate these risks, establish clear communication channels with your fulfillment center or warehouse, implement robust inventory management systems, and regularly review and adjust your processes based on performance data.

A Business.com guide highlights that businesses addressing these common mistakes see a 25% improvement in operational efficiency and a significant reduction in fulfillment errors.

Tips for Maximizing Efficiency in Your Fulfillment Center or Warehouse

Enhancing efficiency in your fulfillment center or warehouse can lead to significant cost savings and improved customer satisfaction. Consider the following strategies:

- Implement Advanced Technology: Utilize inventory tracking and order processing software to streamline operations and reduce manual errors.

- Organize Products Strategically: Develop a system for organizing products based on order frequency and size to facilitate quicker picking and packing.

- Train Staff Effectively: Provide comprehensive training on efficient handling and storage techniques to ensure consistency and accuracy.

- Regularly Review Inventory Levels: Conduct periodic audits to maintain optimal stock levels, avoiding both overstock and stockouts.

Additionally, adopting lean warehouse principles and continuous improvement practices can further enhance operational efficiency and productivity.

A study by Supply Chain Digital found that implementing these tips can boost warehouse efficiency by up to 35%, leading to faster order fulfillment and reduced operational costs.

Ultimately, whether you choose a fulfillment center or a warehouse, aligning your storage and logistics strategy with your business goals is crucial for sustained success.