Measuring Performance in Processing and Receiving

Processing and receiving are critical components of any business that handles inventory or goods. Accurately measuring performance in these areas is essential for ensuring optimal efficiency, maintaining accurate inventory levels, and guaranteeing timely deliveries. In this article, we will delve into the importance of measuring performance in processing and receiving, explore key metrics for tracking and enhancing performance, address common challenges, and provide strategies for streamlining workflows. Additionally, we will examine the role of automation and data analytics in boosting processing and receiving efficiency through real-world case studies of successful implementations.

Why Measuring Performance in Processing and Receiving is Important

Measuring performance in processing and receiving serves several vital purposes:

- Improving Efficiency and Reducing Costs: By analyzing the time and resources required for various tasks, businesses can identify bottlenecks and streamline processes, resulting in faster delivery times and reduced operational costs. According to a 2023 Efficiency Report by ShipScience, companies that optimized their processing workflows saw an average of 20% cost reduction.

- Ensuring Accuracy: Human errors in processing and receiving can lead to costly mistakes, such as shipping incorrect items or miscounting inventory. Measuring performance helps identify these error-prone areas, allowing businesses to implement corrective measures and enhance overall accuracy.

- Monitoring Demand Fluctuations: By collecting data on processing and receiving times and volumes, businesses can swiftly identify trends and adjust operations to meet changing customer demands. This ensures that inventory levels are both adequate and efficient, minimizing waste and delays.

- Fostering Innovation and Growth: Analyzing performance data can uncover opportunities for introducing new technologies or processes that enhance efficiency and reduce costs, leading to increased market share and profitability.

Key Metrics for Measuring Performance in Processing and Receiving

To effectively measure performance in processing and receiving, businesses should establish and monitor the following key metrics:

- Processing and Receiving Times: Measures the duration from order placement to delivery. Identifying delays in this metric helps pinpoint inefficiencies. For instance, businesses can reference industry benchmarks, such as the ShipScience Benchmark Report 2023, which indicates that top-performing companies achieve processing times within 24 hours.

- Inventory Accuracy: Tracks the precision of inventory levels, including stock quantities, locations, and conditions. Accurate inventory management prevents overstocking and understocking, reducing financial losses.

- Order Accuracy: Assesses the percentage of orders fulfilled correctly, encompassing the right items, quantities, and delivery locations. High order accuracy boosts customer satisfaction and loyalty.

- Customer Satisfaction: Gauges customer contentment with the processing and receiving experience through surveys, feedback forms, or online reviews. A survey by ShipScience found that 85% of customers prefer companies with high order accuracy rates.

Additional metrics include:

- Return and Exchange Rate: Monitors the frequency of returns or exchanges due to processing errors, helping to reduce associated costs and improve customer satisfaction.

- Processing and Receiving Costs: Calculates the total expenses related to processing and receiving, including labor, equipment, and materials, enabling businesses to identify cost-saving opportunities.

How to Define and Track Your Metrics for Processing and Receiving

Effective measurement of processing and receiving performance involves the following steps:

- Define Your Goals: Establish clear objectives aligned with your business strategy and customer needs. For example, aiming to reduce processing times by 15% within six months.

- Select Your Metrics: Choose relevant metrics such as processing times, inventory accuracy, and customer satisfaction to track progress toward your goals.

- Collect Data: Gather accurate and consistent data using automated systems or manual tracking methods. Implementing a robust Warehouse Management System (WMS) can streamline data collection.

- Analyze Results: Regularly review collected data to identify trends, pinpoint areas of concern, and uncover opportunities for improvement. Tools like ShipScience Data Analytics can aid in this analysis.

- Create Action Plans: Develop specific, measurable, and time-bound action plans based on your analysis to address identified issues and enhance performance.

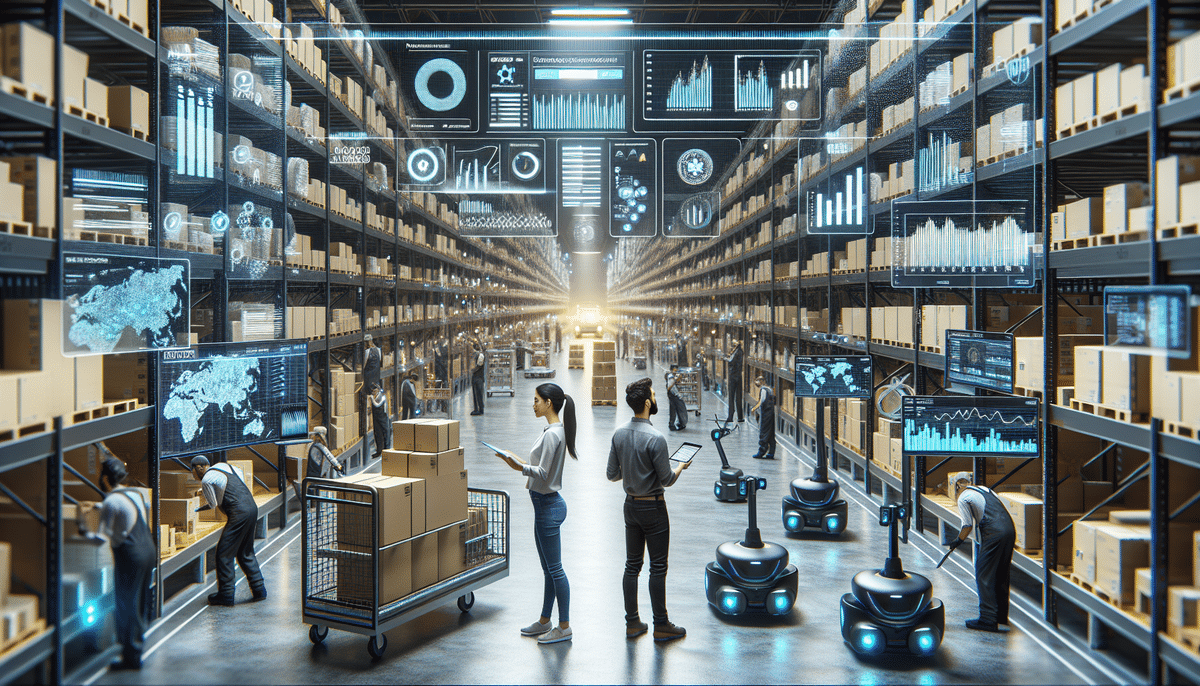

The Role of Automation in Improving Processing and Receiving Performance

Automation can significantly enhance processing and receiving performance by:

- Inventory Management: Automated systems provide real-time tracking of inventory levels, locations, and movements, reducing errors and ensuring accurate stock levels.

- Order Processing: Automation accelerates order processing, minimizes errors, and expedites delivery, leading to higher customer satisfaction.

- Data Analytics: Automated data analysis tools quickly identify trends and areas for improvement, enabling informed decision-making and swift action.

- Communication: Automated communication systems keep customers informed about order status, reducing inquiries and enhancing their experience.

Strategies for Streamlining Your Processing and Receiving Workflow

Implement the following strategies to streamline your processing and receiving workflows:

- Eliminate Redundant Steps: Identify and remove unnecessary or duplicate steps to reduce processing times and increase efficiency.

- Standardize Procedures: Develop and enforce standardized procedures for processing and receiving to ensure consistency and accuracy.

- Invest in Training: Provide comprehensive training for staff on processing and receiving protocols, including any new technologies or software.

- Collaborate with Suppliers: Foster strong relationships with suppliers to improve communication, reduce lead times, and enhance delivery accuracy.

Best Practices for Ensuring Accuracy in Processing and Receiving

To maintain high accuracy in processing and receiving, adhere to these best practices:

- Double-Check: Implement multiple verification steps to ensure accuracy at every stage of the process.

- Use Real-Time Data: Leverage real-time data to keep inventory levels, orders, and shipments accurate and up-to-date.

- Document Everything: Maintain thorough documentation of all processes, including any errors or issues, to facilitate continuous improvement.

- Train Staff: Provide ongoing training to ensure staff are proficient in following procedures and utilizing new technologies.

Common Challenges in Measuring Performance in Processing and Receiving

Businesses often encounter several challenges when measuring performance in processing and receiving:

- Data Collection: Gathering accurate and consistent data can be difficult, particularly in environments with manual processes or disparate systems.

- Overcoming Resistance to Change: Introducing new procedures or technologies may face resistance from staff who are accustomed to existing workflows.

- Identifying Areas for Improvement: Determining specific areas that require enhancement necessitates detailed data analysis, which can be time-consuming.

- Allocating Resources: Devoting sufficient time, money, and personnel to improve processing and receiving performance can be challenging in resource-constrained environments.

How to Use Data Analytics to Improve Processing and Receiving Efficiency

Data analytics is instrumental in enhancing processing and receiving efficiency by:

- Identifying Bottlenecks: Analyze data to pinpoint stages in the process that cause delays and address them to streamline operations.

- Monitoring Trends: Track demand trends to adjust inventory levels and processing capacities accordingly, ensuring optimal resource utilization.

- Predictive Analysis: Use predictive analytics to forecast future demand, anticipate potential challenges, and proactively implement solutions.

- Continuous Improvement: Regularly review and refine processes based on data insights to maintain and enhance operational efficiency.

Case Studies: Successful Approaches to Measuring Performance in Processing and Receiving

Here are some real-world examples of successful performance measurement in processing and receiving:

- Case Study 1: Company X implemented an automated inventory tracking system, resulting in a 50% reduction in processing times and a 90% decrease in inventory errors, significantly boosting overall efficiency and customer satisfaction.

- Case Study 2: Company Y enhanced collaboration with suppliers, leading to improved communication and shortened lead times. This initiative resulted in a 30% reduction in order processing times and a 40% increase in customer satisfaction.

- Case Study 3: Company Z standardized their processing procedures and introduced regular training sessions for staff. These changes led to a 25% reduction in processing errors and a 50% decrease in delivery mistakes, enhancing overall accuracy and customer satisfaction.

Conclusion

Measuring performance in processing and receiving is vital for any business that manages inventory or goods. By defining and tracking key metrics, identifying areas for improvement, and leveraging data analytics and automation, businesses can optimize their processes, enhance accuracy and efficiency, and ultimately provide superior customer service. While challenges exist in measuring performance, the advantages are substantial, and the strategies outlined in this article offer a clear roadmap to achieving operational excellence.