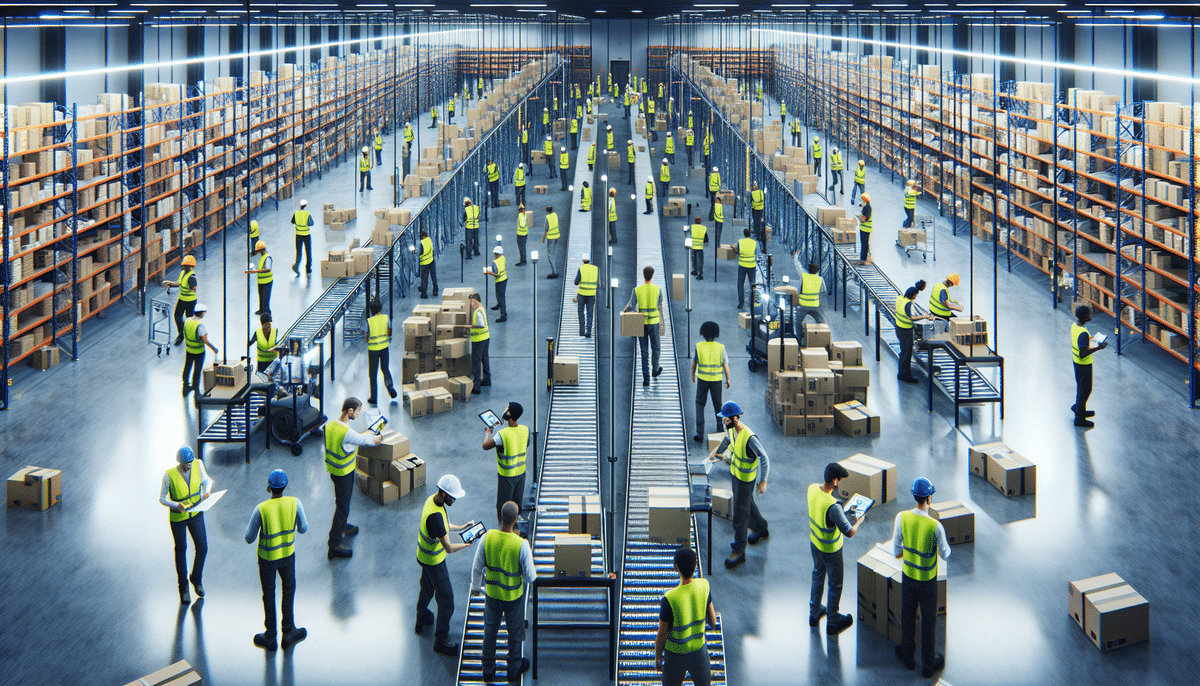

Finding the Balance Between Speed and Accuracy in Pick-Pack Express Lanes

Achieving both speed and accuracy in pick-pack express lanes is essential for optimizing the performance of warehouse operations. Balancing these two factors can be challenging, but it is crucial for ensuring customer satisfaction and maintaining a competitive edge. This article explores the importance of speed and accuracy, best practices for achieving both, and the impact of technology, employee training, and warehouse layout on overall success.

Why Speed and Accuracy are Critical in Pick-Pack Express Lanes

In pick-pack express lanes, orders must be picked and packed swiftly to meet tight turnaround times. Accuracy is paramount to ensure that customers receive the correct items, fostering trust and encouraging repeat business. According to a ShipScience report, 89% of consumers are less likely to return to a site after a poor delivery experience.

Speed is equally important to meet customer demands and stay competitive. Balancing speed with accuracy allows businesses to fulfill orders faster without compromising quality. This balance directly impacts the overall efficiency of the warehouse. Inaccurate orders can lead to shipping delays, backlogs, dissatisfied customers, increased returns, and higher restocking costs.

In today's fast-paced e-commerce industry, customers expect quick and accurate deliveries. Failing to meet these expectations can drive customers to competitors. Investing in technology and employee training to enhance both speed and accuracy is thus crucial for business success.

Best Practices for Achieving Speed and Accuracy in Pick-Pack Express Lanes

- Organize Inventory Efficiently: Arrange products by popularity or size to reduce pick times and minimize mistakes. Grouping similar items helps prevent confusion among pickers.

- Implement Barcoding or RFID Technology: Scanning each item as it is picked and packed ensures the correct items are shipped and speeds up the process by eliminating manual entry.

- Provide Comprehensive Employee Training: Regular training sessions keep pickers and packers up-to-date on the latest procedures and technologies, enhancing overall efficiency and reducing errors.

- Regularly Review and Analyze Processes: Identifying areas of inefficiency or errors allows for targeted improvements, such as adjusting warehouse layouts or reorganizing inventory.

- Implement Quality Control Systems: Establish checks before shipping orders, whether through a separate team or automated systems, to catch and correct mistakes early.

The Impact of Technology on Pick-Pack Express Lanes

Technology plays a significant role in enhancing the efficiency and accuracy of pick-pack express lanes. Automated conveyor systems can expedite the flow of items, while mobile devices enable real-time item location and order tracking. Warehouse Management Systems (WMS) provide valuable data insights to optimize operations, as highlighted by a ShipScience guide.

Barcode scanners and voice-activated picking technology further streamline processes by allowing workers to identify and locate items quickly without manual data entry. Additionally, the integration of artificial intelligence (AI) and machine learning (ML) can predict demand patterns and optimize inventory levels, reducing stockouts and overstocking. These technological advancements lead to cost savings and improved customer satisfaction.

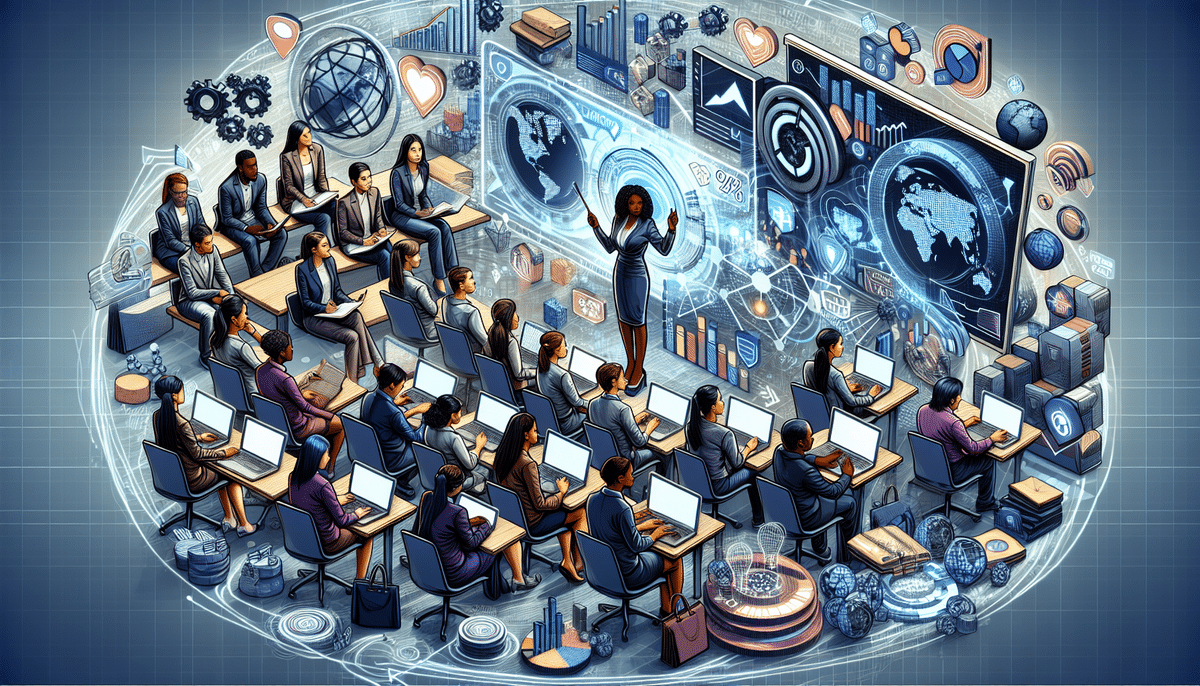

How to Train Your Employees for Maximum Efficiency in Pick-Pack Express Lanes

Employee training is a critical component of successful pick-pack express lanes. Comprehensive onboarding introduces workers to warehouse policies, procedures, and layout, ensuring they understand their roles from the start. Regular training keeps employees engaged and informed about the latest technologies and procedures, enhancing efficiency and reducing errors.

Cross-training employees to perform multiple tasks prevents bottlenecks and maintains smooth workflow. It also allows for greater scheduling flexibility and reduces the risk of burnout by providing variety in job tasks. Investing in employee development increases job satisfaction and retention rates, contributing to a more stable and experienced workforce.

Overcoming Common Challenges in Pick-Pack Express Lanes

Common challenges in pick-pack express lanes include order accuracy, worker efficiency, and inventory management. Conducting regular audits and assessments helps identify areas for improvement. Leveraging technology and providing proper training are effective strategies to address these issues.

Workplace safety is another critical challenge. Workers may be required to lift heavy items or use equipment that poses injury risks. Providing proper safety equipment, implementing ergonomic workstations, and conducting regular safety audits can mitigate these risks. Ensuring a safe working environment not only protects employees but also maintains operational efficiency.

Measuring Performance: Key Metrics for Pick-Pack Express Lanes

Measuring performance is essential for identifying areas of improvement and optimizing pick-pack express lanes. Key metrics include:

- Order Processing Time: The time taken to complete an order from picking to shipping.

- Inventory Accuracy: The precision of inventory records compared to actual stock levels.

- Orders Shipped Per Hour: The volume of orders processed within an hour.

- Order Error Rate: The frequency of incorrect items, quantities, or orders shipped.

- Employee Safety Metrics: The number of workplace injuries and safety incidents.

Tracking these metrics allows businesses to make data-driven decisions to enhance efficiency and reduce errors. Prioritizing employee safety also contributes to a positive work culture and improved overall performance.

The Importance of Quality Control in Pick-Pack Express Lanes

Quality control ensures that orders are delivered accurately and on time. Implementing quality control processes involves:

- Reviewing order accuracy before shipping.

- Inspecting products for damage.

- Conducting regular inventory checks.

- Maintaining clear communication channels for swift issue resolution.

A clean and organized workspace is also vital. Regularly sanitizing workstations, properly storing products, and maintaining equipment prevent errors and accidents, promoting both efficiency and safety.

How to Optimize Your Warehouse Layout for Faster and More Accurate Pick-Packing

The layout of a warehouse significantly impacts the efficiency of pick-pack express lanes. Optimizing the layout involves:

- Strategic Product Placement: Arranging items by popularity or size to reduce pick times.

- Efficient Packing Areas: Positioning packing materials and stations to streamline the packing process.

- Incorporating Technology: Using automated conveyor systems and mobile devices to facilitate item movement and reduce search times.

- Regular Audits: Continuously evaluating and adjusting the layout based on operational needs and performance data.

Ensuring worker safety is also crucial. Clear pathways, proper storage heights, and the availability of safety equipment like forklifts and gear enhance both safety and efficiency.

Case Studies: Successful Strategies for Balancing Speed and Accuracy in Pick-Pack Express Lanes

Successful strategies for balancing speed and accuracy in pick-pack express lanes are exemplified by various companies:

- Automated Picking Systems: One company increased its order volume by 500% by implementing an automated picking system that uses voice commands to guide workers.

- Barcode Scanning Technology: Another company improved its overall accuracy by over 90% by adopting barcode scanning technology.

Studying these case studies and adapting their strategies to your own operations can significantly optimize your pick-pack express lanes for both speed and accuracy.

In conclusion, balancing speed and accuracy in pick-pack express lanes is critical for operational success. By implementing best practices, leveraging technology, training employees, and optimizing warehouse layouts, businesses can achieve the necessary efficiency to thrive in the competitive e-commerce landscape.

It is essential to tailor these strategies to the specific needs and goals of your operation. Whether prioritizing rapid order fulfillment through voice-directed picking systems or enhancing accuracy with barcode scanning technology, assessing your unique circumstances will help determine the most effective approach for your business.