How to Take Advantage of Decreasing Costs and Optimize Outbound Inventory Staging

Managing inventory effectively is crucial for any business aiming to reduce costs, enhance delivery times, and boost customer satisfaction. One of the most vital components in inventory management is the outbound inventory staging process. This article delves into the significance of outbound inventory staging, the advantages of decreasing inventory costs, and provides actionable tips for optimizing your outbound inventory staging process.

Understanding the Importance of Outbound Inventory Staging

Outbound inventory staging involves preparing and consolidating products for shipment. The primary objective is to ensure that the right items are delivered on time, in optimal condition, and at the lowest possible cost. This process encompasses several critical steps, including picking, packing, and shipping. When executed efficiently, outbound inventory staging can significantly enhance your company's profitability and customer satisfaction.

One of the key advantages of outbound inventory staging is the reduction of shipping errors and delays. By consolidating products and ensuring proper labeling and packaging, the risk of items being lost or damaged during transit is minimized. Furthermore, outbound inventory staging allows businesses to optimize shipping costs by leveraging bulk discounts and negotiating better rates with carriers. According to a 2023 Supply Chain Report, companies that implemented optimized outbound staging saw an average cost reduction of 15% in shipping expenses.

Benefits of Decreasing Inventory Costs for Your Business

Reducing inventory costs offers multiple benefits:

- Increased Working Capital: Frees up funds that can be reinvested into other areas of the business.

- Improved Inventory Turnover: Enhances profitability by increasing the rate at which inventory is sold and replaced.

- Reduced Storage and Handling Costs: Lowers overall expenses by minimizing the need for extensive storage facilities and labor.

Additionally, lowering inventory costs enhances a business's agility, allowing quicker responses to market changes and customer demand shifts. A study by ShipScience Research indicates that businesses with optimized inventory management systems are 20% more responsive to market trends.

Moreover, reducing inventory costs contributes to a more sustainable business model by minimizing excess inventory and waste, thereby lowering the environmental impact and enhancing the company's reputation as a socially responsible entity.

Tips for Optimizing Outbound Inventory Staging

Optimizing your outbound inventory staging process can lead to significant cost savings and improved delivery performance. Here are some strategies to consider:

Streamline Your Picking Process

Efficient picking is essential for reducing labor costs and enhancing accuracy. Implement technologies such as barcode scanning or automated picking systems to increase efficiency. For instance, automated picking systems can reduce picking errors by up to 30%.

Automate Your Packing Process

Automation in packing minimizes labor costs and enhances accuracy. Investing in packing automation equipment like tape machines or label applicators can streamline operations and reduce the likelihood of shipping errors, which can prevent costly returns and improve customer satisfaction.

Utilize Data Analytics

Leveraging data analytics helps identify inefficiencies and optimize the outbound staging process. Utilize software that tracks metrics such as cycle times and error rates to make informed decisions. According to ShipScience Insights, companies using data analytics in inventory management report a 25% increase in operational efficiency.

Improve Your Shipping Procedure

Enhancing shipping procedures can lead to reduced costs and faster delivery times. Negotiate better shipping rates with transportation providers and optimize packaging to decrease weight and volume. This approach not only cuts costs but also expedites the delivery process.

Implement Quality Control Measures

Quality control ensures the efficiency and accuracy of outbound inventory staging. Establish a system for inspecting items before shipment to maintain quality standards, thereby reducing returns and increasing customer satisfaction.

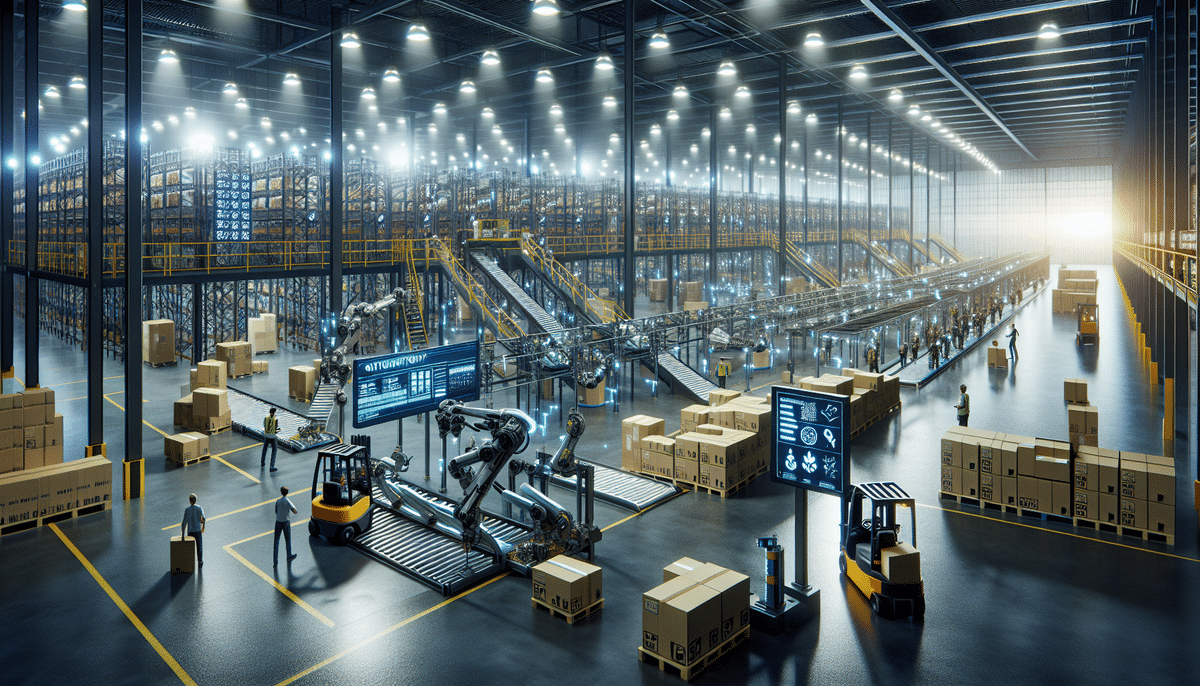

The Role of Technology in Optimizing Outbound Inventory Staging

Technology plays a pivotal role in optimizing outbound inventory staging. Automation tools, data analytics, and other technological solutions can save time and reduce costs. Investing in these technologies streamlines workflows and enhances operational efficiency.

Real-time inventory tracking through RFID tags and barcode scanners allows businesses to monitor the movement of goods within the warehouse accurately. This visibility helps identify and address issues such as misplaced items or staging bottlenecks promptly.

Additionally, technology improves the accuracy of outbound inventory staging by automating tasks like data entry and order processing, thereby minimizing human error. This leads to fewer costly mistakes and higher customer satisfaction, ultimately driving increased sales and revenue.

Strategies to Reduce Outbound Inventory Costs

Implementing effective strategies can significantly reduce outbound inventory costs:

Implement a Just-in-Time (JIT) Inventory System

A JIT system minimizes the amount of inventory held, reducing storage and handling costs. It also improves inventory turnover rates and lowers the risk of obsolete inventory.

Collaborate with Suppliers

Working closely with suppliers to enhance lead times and consolidate orders can decrease transportation and handling costs. Implementing an Electronic Data Interchange (EDI) system facilitates better communication and data sharing with suppliers.

Optimize Your Warehouse Layout

An optimized warehouse layout reduces transportation costs and boosts efficiency. Organize inventory based on demand trends and consider implementing a cross-docking system to minimize handling costs.

Implement a Demand Forecasting System

Accurate demand forecasting helps predict customer needs and adjust inventory levels accordingly, reducing the risks of overstocking or understocking and associated storage and handling costs.

Use Sustainable Packaging Materials

Adopting sustainable packaging materials not only reduces transportation costs but also enhances your company's environmental footprint. Opt for recyclable, biodegradable, or renewable materials to support sustainability goals.

Best Practices for Effective Outbound Inventory Management

Adhering to best practices ensures efficient outbound inventory management:

Regular Cycle Counting and Auditing

Frequent cycle counting and auditing maintain inventory accuracy and prevent losses. Implementing a real-time inventory tracking system enhances accuracy and ensures reliable inventory data.

Manage Lead Times and Order Fulfillment

Effective management of lead times and order fulfillment guarantees timely and accurate deliveries. Collaborate with logistics providers to optimize supply chain processes and enhance delivery performance.

Continuously Optimize Your Processes

Ongoing optimization of outbound inventory processes reduces costs and increases efficiency. Monitor key metrics like order accuracy and cycle times to identify improvement areas and implement necessary changes.

Implement Safety Stock Levels

Maintaining safety stock prevents stockouts and ensures sufficient inventory to meet customer demand. Consider factors such as lead times, demand variability, and supplier reliability when determining appropriate safety stock levels.

Utilize Data Analytics

Data analytics offers valuable insights into outbound inventory management. Use data to identify trends, forecast demand, and optimize inventory levels. Invest in inventory management software with robust data analytics capabilities for enhanced decision-making.

Case Study: Successful Implementation of Outbound Inventory Optimization

A leading e-commerce company implemented several outbound inventory optimization strategies, resulting in significant improvements. By streamlining their picking and packing processes, optimizing their warehouse layout, and collaborating with suppliers, they reduced inventory costs by 20% and improved delivery times by 30%.

The company also adopted a real-time inventory tracking system, enabling them to monitor inventory levels and demand patterns accurately. This system facilitated informed decision-making regarding reorder points and quantities, minimizing the risks of overstocking and stockouts.

Furthermore, investment in employee training programs enhanced workforce skills and productivity, leading to increased operational efficiency and improved customer service.

Common Mistakes to Avoid in Outbound Inventory Staging

Avoiding common pitfalls is essential for effective outbound inventory staging:

Poor Record-Keeping

Inaccurate record-keeping leads to incorrect inventory counts and misplaced items. Implementing a real-time inventory tracking system enhances accuracy and reliability.

Inefficient Picking and Packing Processes

Outdated or inefficient picking and packing methods increase labor costs and shipping errors. Automation can streamline these processes, reducing costs and improving accuracy.

Not Collaborating with Suppliers

Lack of collaboration with suppliers escalates transportation and handling costs. Implementing an EDI system improves communication and data sharing, fostering better relationships and cost efficiencies.

Ignoring Customer Feedback

Disregarding customer feedback can lead to decreased satisfaction and lost sales. Establishing a system to collect and analyze feedback helps refine outbound inventory staging processes, enhancing the customer experience.

Future Trends in Outbound Inventory Management and Cost Optimization

The landscape of outbound inventory management is evolving with several emerging trends:

- Automation and Robotics: Increased use of automated systems and robotics to streamline processes.

- Real-Time Data Analytics: Growing adoption of data analytics for better decision-making and process optimization.

- Last-Mile Delivery Innovations: Introduction of drones and autonomous vehicles for efficient last-mile delivery.

- Artificial Intelligence (AI) and Machine Learning: AI-powered systems analyze vast data sets to identify patterns, predict demand, and optimize inventory levels.

According to a 2023 Industry Forecast, businesses investing in AI and machine learning technologies are expected to see a 35% improvement in inventory accuracy and a 25% reduction in fulfillment times.

How to Measure the Success of Your Outbound Inventory Management Strategy

Measuring the effectiveness of your outbound inventory management strategy is crucial for continuous improvement:

- Inventory Turnover Rate: Measures how quickly inventory is sold and replaced.

- Order Accuracy: Tracks the percentage of orders fulfilled correctly.

- Delivery Times: Monitors the speed at which orders are delivered to customers.

- Cost Savings: Calculates the reduction in inventory-related expenses.

- Customer Satisfaction: Assessed through feedback surveys, reviews, and ratings.

Regularly analyze these metrics to identify trends and areas for improvement. Adjust your strategies based on data insights to ensure your outbound inventory management remains optimized for success.

Importance of Collaboration between Supply Chain Partners for Successful Outbound Inventory Staging

Collaboration among supply chain partners is vital for effective outbound inventory staging. Enhanced communication and data sharing facilitate the identification of improvement areas and process optimization. Partnering with logistics providers and suppliers ensures a seamless supply chain, reducing costs and improving overall efficiency.

How Outsourcing Can Help Optimize Your Outbound Inventory Costs

Outsourcing outbound inventory functions to specialized logistics providers can significantly optimize costs. By outsourcing non-core activities such as transportation and warehousing, businesses can leverage the expertise and economies of scale of logistics partners, freeing up resources to focus on core business activities and enhancing operational efficiency.

Key Metrics for Tracking and Improving Your Outbound Inventory Management Strategy

Monitoring key metrics is essential for tracking and enhancing your outbound inventory management strategy:

- Inventory Turnover Rate: Indicates how efficiently inventory is being utilized.

- Order Accuracy: Reflects the precision of order fulfillment.

- Delivery Times: Measures the efficiency of the delivery process.

- Cost Savings: Tracks reductions in inventory-related expenses.

Continuously monitor these metrics to pinpoint areas needing improvement and to implement effective optimization strategies. Utilizing inventory management software with robust analytics capabilities can aid in tracking these metrics accurately.