A Comprehensive Guide to Tire Fulfillment

Tire fulfillment is a critical aspect of any business involved in the import, export, or distribution of tires. The timely and efficient delivery of tires to end-users is essential for maintaining a satisfied customer base and building a positive reputation in the market. In this comprehensive guide, we will explore the basics of tire fulfillment, its importance for businesses, different types of tires, factors to consider while choosing a tire fulfillment provider, best practices for managing tire fulfillment operations, automation, enhancing customer experience, overcoming challenges, and future trends and predictions.

Table of Contents

- Understanding the Basics of Tire Fulfillment

- Importance of Efficient Tire Fulfillment for Your Business

- Types of Tires and Their Fulfillment Needs

- Factors to Consider While Choosing a Tire Fulfillment Provider

- Best Practices for Managing Tire Fulfillment Operations

- Automating Tire Fulfillment: Pros & Cons

- Enhancing Customer Experience with Seamless Tire Fulfillment Process

- Challenges in Tire Fulfillment and How to Overcome Them

- The Future of Tire Fulfillment: Trends and Predictions

Understanding the Basics of Tire Fulfillment

Tire fulfillment encompasses the entire process of storing, processing, and delivering tires from the manufacturer or distributor to the end customer. This involves:

- Receiving tires from suppliers

- Assessing the type and quality of tires

- Storing them in a warehouse

- Processing and packing orders

- Shipping them to customers through various logistics channels

Effective tire fulfillment requires partnering with an experienced and reliable fulfillment provider that understands the industry and has the necessary resources to ensure efficient processes and timely deliveries.

Proper storage is vital to maintain the quality and integrity of tires. This includes:

- Using climate-controlled environments to prevent damage from extreme temperatures

- Ensuring tires are stored to prevent any damage or deformation

- Implementing inventory tracking systems to maintain adequate stock levels

Importance of Efficient Tire Fulfillment for Your Business

An efficient tire fulfillment process is essential for any business involved in tire distribution. It ensures:

- Timely deliveries

- Accurate inventory management

- On-time order processing

These factors lead to customer satisfaction, which in turn drives more business opportunities, positive reviews, and brand recognition. According to a 2023 industry report, businesses with streamlined fulfillment operations experience a 20% increase in customer retention.

Moreover, efficient tire fulfillment can help businesses:

- Save costs and increase profitability by reducing time and resources required for inventory management

- Avoid costly mistakes such as incorrect orders or delayed deliveries

- Enhance overall logistics operations

Investing in efficient tire fulfillment is not only beneficial for customer satisfaction but also for the financial health of the business.

Types of Tires and Their Fulfillment Needs

Tires come in various types, each with unique fulfillment needs that determine the specific requirements for storage, handling, and transportation. The main types include:

- Passenger Tires: Designed for cars and SUVs, these are typically smaller and lighter, making them easier to handle and store.

- Light Truck Tires: Intended for pickup trucks and vans, these are larger and heavier, requiring more space and specialized handling equipment.

- Medium Truck Tires: Used for commercial vehicles, these tires demand robust storage solutions due to their size and weight.

- Off-Road Tires: Designed for rugged terrain, they have aggressive tread patterns and tougher materials, necessitating specialized handling to prevent damage.

- Specialty Tires: Including racing and snow tires, these have specific storage and handling requirements due to their unique designs and purposes.

Fulfillment providers must understand these specifications and possess the necessary expertise and infrastructure to handle the shipment of different tire types effectively.

Factors to Consider While Choosing a Tire Fulfillment Provider

When selecting a tire fulfillment provider, businesses should evaluate several critical factors to ensure a successful partnership:

- Experience and Industry Knowledge: Providers with a deep understanding of the tire industry can better address specific fulfillment needs.

- Infrastructure and Resources: Adequate warehouse space, advanced technology, and efficient logistics are essential.

- Warehousing Facilities: Climate-controlled and secure storage facilities help maintain tire quality.

- Transportation Capabilities: Reliable shipping options and partnerships with experienced carriers are crucial.

- Reliability and Track Record: A history of on-time deliveries and consistent service quality indicates a dependable provider.

- Customer Support: Responsive and effective customer service ensures smooth operations and quick resolution of issues.

- Technology and Software Capabilities: Advanced inventory management, order processing, and tracking systems enhance efficiency. Integration with existing business systems is also important.

Ensuring that the fulfillment provider offers real-time visibility into inventory levels, order status, and shipping information can help businesses make informed decisions and optimize their operations.

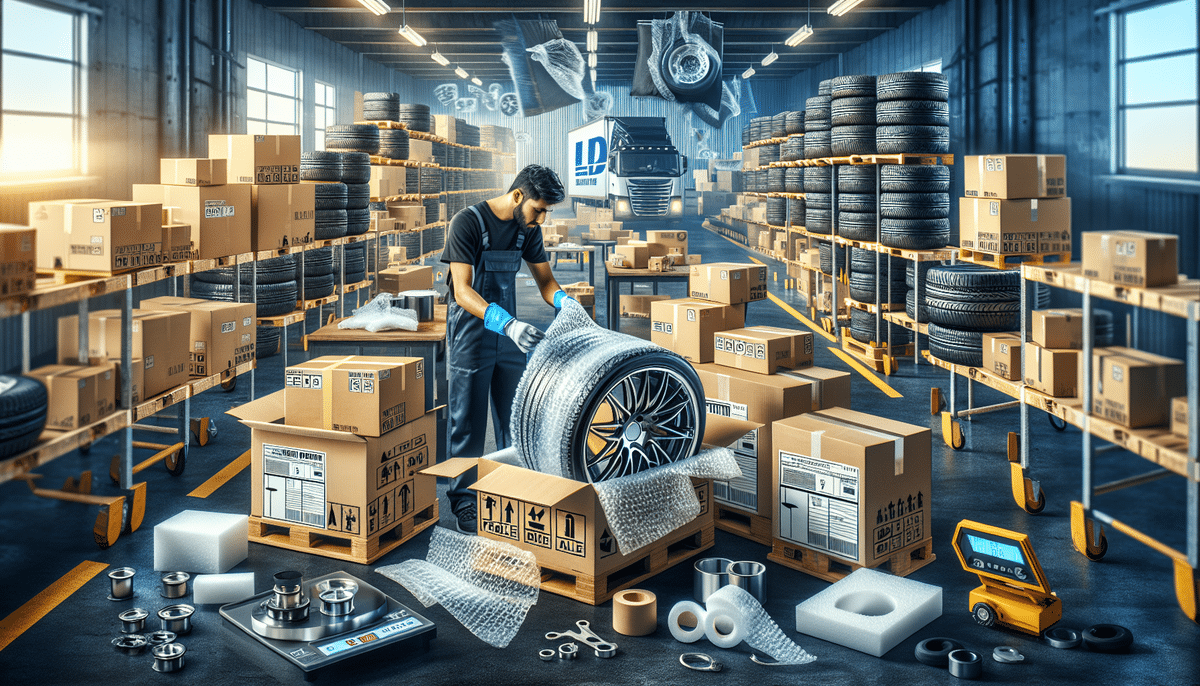

Best Practices for Managing Tire Fulfillment Operations

Effective management of tire fulfillment operations involves several best practices to ensure efficiency and accuracy:

- Efficient Inventory Management: Implementing robust systems to track inventory levels and predict demand.

- Timely Order Processing: Ensuring that orders are processed promptly to facilitate quick fulfillment.

- Accurate Packing: Using proper materials and methods to pack tires, preventing damage during transit.

- Automated Systems: Leveraging technology to automate repetitive tasks, reducing errors and speeding up processes.

- Quality Control: Setting stringent quality checks to ensure all orders meet the required standards before shipping.

Additionally, maintaining excellent customer service is paramount. Fulfillment providers should have a dedicated customer service team to handle inquiries, complaints, and returns efficiently. Regularly collecting and analyzing customer feedback can help identify areas for improvement and enhance the overall customer experience.

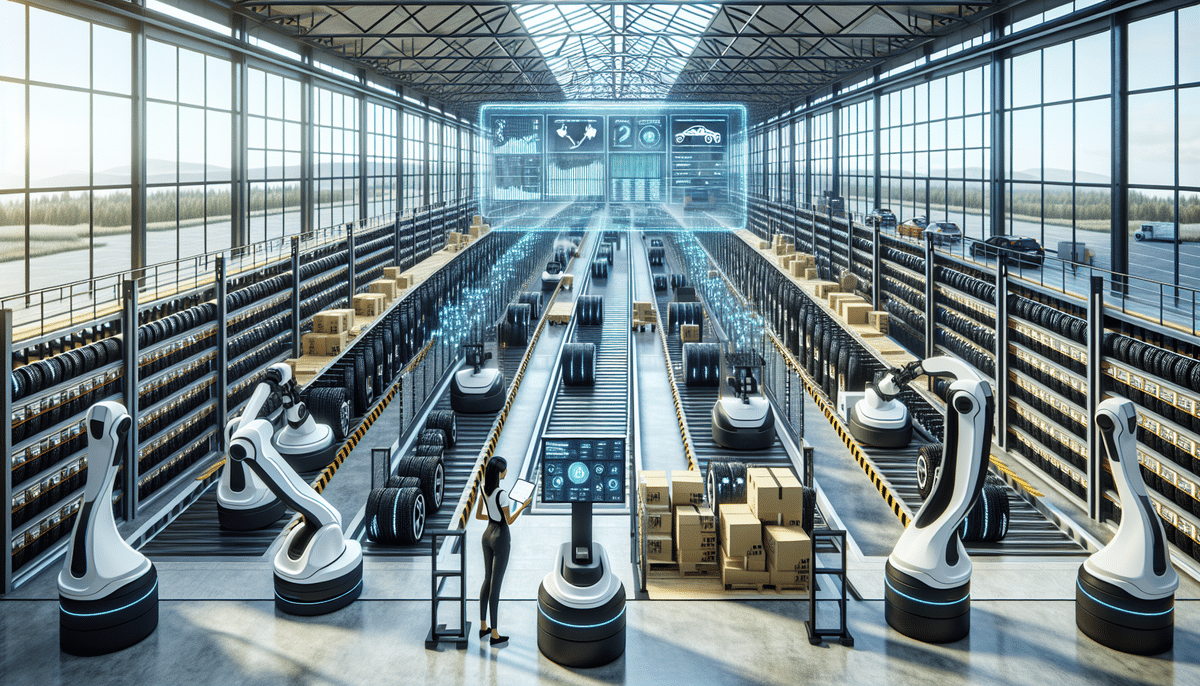

Automating Tire Fulfillment: Pros & Cons

Automation in tire fulfillment can significantly improve efficiency and accuracy. The benefits include:

- Increased Efficiency: Automated systems can handle tasks faster than manual processes.

- Reduced Errors: Minimizing human intervention decreases the likelihood of mistakes in order processing.

- Enhanced Tracking: Automation enables better tracking and monitoring of products throughout the supply chain.

However, there are also potential drawbacks:

- High Implementation Costs: Initial investments in technology and infrastructure can be substantial.

- Specialized Expertise Required: Operating and maintaining automated systems may require specialized skills.

- Job Displacement: Automation can lead to the reduction of certain job roles, impacting the workforce.

Despite these challenges, the long-term benefits of automation often outweigh the drawbacks. Businesses should carefully assess their needs and resources before deciding to implement automation in their tire fulfillment processes.

Enhancing Customer Experience with a Seamless Tire Fulfillment Process

In today's competitive market, providing a seamless customer experience in tire fulfillment is essential. Customers expect:

- Real-time updates on order status

- Timely notifications about deliveries

- Hassle-free returns and exchanges

To meet these expectations, fulfillment providers should:

- Leverage Technology: Utilize digital platforms to communicate effectively with customers and provide transparency.

- Offer Personalized Recommendations: Suggest tires based on the customer's vehicle make and model to aid in informed decision-making.

- Provide Installation Services: Partner with local installers or offer in-house services to enhance convenience for customers.

- Focus on Sustainability: Use eco-friendly packaging and optimize delivery routes to minimize environmental impact.

According to a recent study, businesses that prioritize sustainable fulfillment practices see a 15% increase in customer loyalty.

Challenges in Tire Fulfillment and How to Overcome Them

Tire fulfillment involves several challenges that businesses must navigate to ensure smooth operations:

- High-Volume Orders: Managing large volumes of orders, especially during peak seasons, requires scalable solutions.

- Seasonal Fluctuations in Demand: Anticipating and preparing for seasonal changes can prevent stockouts or overstocking.

- Inventory Storage Capacity: Allocating adequate space to store various types of tires without compromising quality.

- Quality Control: Maintaining consistent quality standards to prevent faulty or damaged products from reaching customers.

- Regulatory Requirements: Complying with local and international regulations related to tire transportation and storage.

To overcome these challenges, fulfillment providers should:

- Invest in Advanced Technology: Implement robust inventory management and order processing systems.

- Collaborate with Experienced Logistics Partners: Ensure reliable transportation and handling of tires.

- Establish Quality Control Processes: Regular inspections and standards to maintain product integrity.

- Plan for Seasonality: Use predictive analytics to forecast demand and adjust inventory accordingly.

Transportation of tires poses specific challenges due to their size and weight. To address this, fulfillment providers should:

- Partner with carriers experienced in handling bulky and heavy shipments

- Utilize specialized equipment to prevent damage during transit

- Implement GPS tracking systems to monitor shipments and ensure timely delivery

The Future of Tire Fulfillment: Trends and Predictions

The tire fulfillment industry is evolving with several emerging trends that will shape its future:

- Automated Fulfillment Processes: Increased use of automation to enhance efficiency and accuracy.

- Robotics and Drones: Deployment of robotics for handling and drones for delivery to streamline operations.

- Artificial Intelligence and Data Analytics: Utilizing AI for demand forecasting, inventory optimization, and customer insights.

- Eco-Friendly Transportation: Adoption of electric vehicles and sustainable practices to reduce carbon footprint.

- Blockchain Technology: Implementing blockchain for secure and transparent tracking of the supply chain, enhancing trust and reducing fraud.

For example, blockchain technology can provide a secure and transparent way to track the entire supply chain, from manufacturer to end customer. This can improve inventory management, reduce fraud, and enhance customer trust.

As these technologies continue to advance, businesses must invest in the right tools and partnerships to stay competitive and meet evolving customer expectations.

Tire fulfillment is an essential process that businesses must continuously optimize to ensure customer satisfaction and competitiveness. By understanding the fundamentals, recognizing the specific needs of different tire types, selecting the right fulfillment partner, implementing best practices, and embracing future trends, businesses can enhance their fulfillment operations and maintain a strong position in the market.