The Ultimate Guide to Pick and Pack Methods

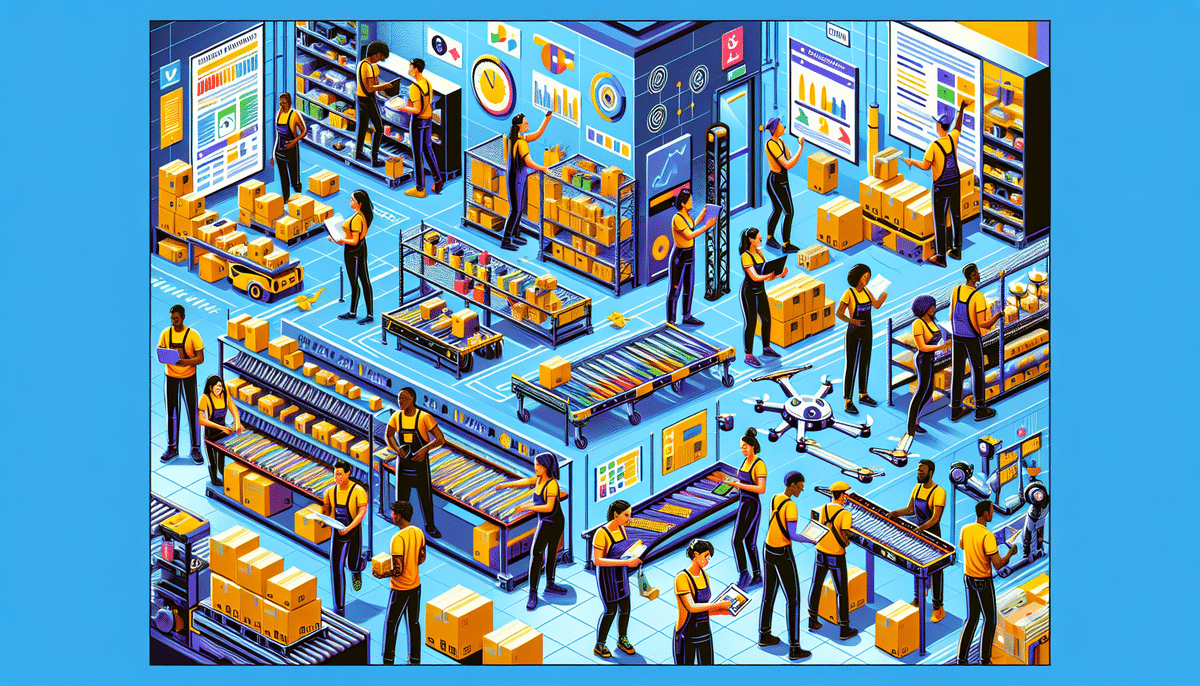

If you run a business that involves shipping products to customers, you've likely heard of the pick and pack method. Pick and pack is a fulfillment technique used in warehousing and order fulfillment to ensure that items are selected and packaged correctly and efficiently. In this article, we'll provide you with a comprehensive guide to pick and pack methods, including the different types, their strengths and weaknesses, how to choose the right one for your business, and more.

Introduction: What is Pick and Pack?

Pick and pack is a fulfillment process in which inventory is picked from storage, packaged, and then shipped out to customers. The process involves selecting the correct item from the warehouse and then packaging it for shipping. This method is used by businesses of all sizes across a variety of industries, but it is especially common in e-commerce and retail.

One of the key benefits of pick and pack is that it allows businesses to streamline their operations and reduce costs. By outsourcing the fulfillment process to a third-party provider, businesses can save money on warehousing, labor, and shipping expenses. Additionally, pick and pack providers often have advanced technology and systems in place to ensure accurate and efficient order fulfillment, which can lead to increased customer satisfaction and repeat business.

Why is the Pick and Pack Method Important?

The pick and pack method is essential for businesses that need to ship products to customers quickly and efficiently. Having an organized and streamlined system in place can enhance the customer experience by reducing shipping times and minimizing errors. Additionally, an efficient picking and packing process can help reduce costs associated with warehousing and shipping, which can ultimately lead to higher profits.

Implementing a pick and pack method can also improve inventory management. By keeping track of inventory levels and organizing products in a logical manner, businesses can reduce the risk of stockouts and overstocking. This can help businesses save money by avoiding the costs associated with excess inventory and lost sales due to stockouts. Overall, the pick and pack method is a crucial component of any successful e-commerce or retail business.

Different Types of Pick and Pack Methods

There are several different types of pick and pack methods, each with its own strengths and weaknesses. Here are the most common methods:

- Discrete Order Picking: This method involves picking one order at a time, as they come in. It's ideal for businesses with a relatively low volume of orders and a small amount of inventory to manage.

- Batch Picking: Batch picking involves gathering multiple orders at the same time. It's efficient for processing a high volume of orders with similar products.

- Zone Picking: Zone picking involves dividing the warehouse into zones and assigning workers to each zone. This method is helpful for larger warehouses with high volumes of products.

- Wave Picking: Wave picking involves processing multiple orders at once, but in smaller batches. It's ideal for businesses that get a steady stream of orders throughout the day.

Another pick and pack method that is gaining popularity is Robotics Picking: This method involves the use of robots to pick and pack products. It's ideal for businesses that have a high volume of orders and need to process them quickly. Robotics picking is also helpful for reducing errors and increasing efficiency.

Another factor to consider when choosing a pick and pack method is order accuracy: Some methods, such as discrete order picking, may be more accurate because each order is picked individually. However, other methods, such as batch picking, may be less accurate because multiple orders are being processed at once. It's important to weigh the benefits of efficiency versus accuracy when choosing a pick and pack method.

Comparison of Different Pick and Pack Methods

Each pick and pack method has its own advantages and disadvantages, depending on your specific business needs. Here's a comparison of the different methods:

| Method | Advantages | Disadvantages |

|---|---|---|

| Discrete Order Picking | Efficient for small volumes of inventory | Inefficient for larger orders or high volumes of inventory |

| Batch Picking | Efficient for orders with similar products | Not ideal for orders with varying product types |

| Zone Picking | Efficient for large warehouses and high volumes of products | Requires more coordination and communication among workers |

| Wave Picking | Efficient for processing multiple orders throughout the day | Can be less efficient for larger orders |

| Robotics Picking | Reduces errors and increases efficiency | High initial investment and maintenance costs |

It's important to consider the size and layout of your warehouse when choosing a pick and pack method. For example, zone picking may not be efficient for smaller warehouses with limited space, while batch picking may be more suitable. Additionally, the type of products you are handling can also impact the effectiveness of each method. For example, wave picking may not be ideal for fragile or irregularly shaped items that require more careful handling.

Strengths and Weaknesses of Each Method

Now let's take a closer look at the strengths and weaknesses of each method:

Discrete Order Picking

Strengths:

- Easy to manage for small volumes of inventory

- Minimizes errors since each order is picked individually

Weaknesses:

- Inefficient for larger orders or higher volumes of inventory

- Can lead to more travel time for workers, since each order is separate

Batch Picking

Strengths:

- Efficient for orders with similar products

- Reduces travel time for workers if done correctly

Weaknesses:

- Not ideal for orders with varying product types

- Requires coordination and planning to ensure the right products are picked

Zone Picking

Strengths:

- Efficient for larger warehouses and high volumes of products

- Can decrease travel time for workers

Weaknesses:

- Requires more coordination and communication among workers

- Can be less efficient if zones are not optimized correctly

Wave Picking

Strengths:

- Efficient for processing multiple orders throughout the day

- Can reduce travel time for workers

Weaknesses:

- Can be less efficient for larger orders

- Requires more planning to ensure orders are picked correctly

Robotics Picking

Strengths:

- Reduces errors and increases efficiency

- Handles high volumes of orders quickly

Weaknesses:

- High initial investment and maintenance costs

- Requires technical expertise to manage robotic systems

How to Choose the Right Pick and Pack Method for Your Business

Now that you're familiar with the different pick and pack methods, it's time to determine which one is right for your business. Consider the following factors when making your decision:

- Order volume: How many orders do you receive each day, week, or month?

- Inventory size: How many products do you have in your warehouse?

- Product variability: Are your products similar, or do they vary significantly in size and shape?

- Geographic location: Where are your customers located?

- Budget: What is your budget for implementing a pick and pack system?

- Technology integration: Do you have or plan to use any technologies like WMS or robotics?

By considering the above factors, you'll be able to identify which pick and pack method will work best for your business.

Designing an Efficient Picking and Packing Process

Once you've determined which pick and pack method is right for your business, it's time to start designing an efficient picking and packing process. Here are a few steps to follow:

- Organize your inventory: Make sure your products are easy to find and identify. Use clear labeling and categorize products logically.

- Design your warehouse layout: Map out your warehouse to optimize the flow of products and workers. Consider using layout software to plan efficient paths.

- Choose the right equipment: Ensure you have the right tools, such as forklifts and pallet jacks, to move inventory efficiently.

- Implement inventory management systems: Utilize systems like inventory management software to track stock levels and movements.

- Train your employees: Ensure that your employees are properly trained on the pick and pack process and any equipment they'll be using.

- Monitor and optimize: Regularly review your pick and pack process to identify areas for improvement and implement changes as needed.

Best Practices for Pick and Pack Efficiency

Here are some additional best practices to help you increase efficiency in your pick and pack process:

- Minimize travel time: Organize your products so that workers don't have to travel far to pick them up. Place frequently picked items near packing stations.

- Optimize your picking path: Plan the most efficient route for workers to take when selecting items to pick. Implement slotting strategies to reduce movement.

- Use barcode scanning: Implement barcode scanning to reduce human error and increase accuracy. Technologies like barcode scanners can streamline the process.

- Automate where possible: Automate certain parts of the process, such as label printing, to reduce the risk of errors and save time.

- Implement quality control checks: Regularly verify orders before shipping to ensure accuracy and prevent returns.

- Utilize data analytics: Analyze pick and pack data to identify trends, inefficiencies, and opportunities for improvement.

Common Mistakes to Avoid in Pick and Pack Operations

As with any process, there are certain mistakes that can disrupt the flow of your pick and pack operations. Here are a few to avoid:

- Overcomplicating the process: Keep the process as simple as possible to avoid confusion and increase efficiency.

- Not training employees properly: Ensure that your employees are trained on all aspects of the process and any equipment they'll be using.

- Not updating inventory regularly: Keep your inventory system up-to-date to avoid discrepancies that can lead to errors in the pick and pack process.

- Not verifying orders before shipping: Double-check all orders to ensure that the correct items have been picked and packaged.

- Poor warehouse layout: An inefficient warehouse layout can increase travel time and reduce picking efficiency.

Picking Strategies to Optimize Productivity

Here are a few strategies you can use to optimize productivity during the picking process:

- Use smaller cartons: Smaller cartons are easier to handle, which can reduce the time it takes to pick and pack orders.

- Group SKUs together: Grouping similar products together makes it easier to pick multiple items at once, reducing time and effort.

- Go hands-free: Use tools such as wearable barcode scanners to help workers stay efficient by freeing up their hands.

- Implement pick-to-light systems: These systems guide pickers to the correct locations quickly and accurately.

- Cross-docking: Directly transferring products from inbound to outbound shipping without storing them can reduce handling time.

Packing Strategies to Ensure Product Safety

Here are a few strategies you can use to ensure that products are packed safely:

- Use appropriate packaging materials: Use materials that will protect the product during shipping, such as bubble wrap, packing peanuts, or reinforced boxes.

- Label fragile items: Clearly label items that are fragile or require special handling to prevent damage during transit.

- Inspect packages before shipping: Double-check packages for damage or leaks before shipping them out to customers.

- Standardize packaging processes: Develop standardized packing procedures to ensure consistency and reduce errors.

- Use tamper-evident packaging: This can help ensure that products are secure and have not been tampered with during shipping.

Role of Technology in Streamlining Pick and Pack Processes

Advancements in technology have made it easier than ever to streamline the pick and pack process. Here are a few ways that technology can help:

- Barcode scanning and RFID: These technologies can improve accuracy and speed up the process of identifying and tracking inventory.

- Automated label printing: Automated label printing can reduce the time it takes to label packages and reduce the risk of errors.

- Warehouse management systems (WMS): WMS software can help optimize the pick and pack process by providing real-time inventory data and optimizing picking routes.

- Automation and robotics: The use of automated conveyors, sorting systems, and robotics can significantly increase the speed and efficiency of pick and pack operations.

- Artificial intelligence: AI can analyze data to predict order patterns, optimize inventory levels, and improve overall efficiency.

Case Studies: Successful Implementation of Pick and Pack Methods

Now let's take a look at a few case studies of businesses that have successfully implemented pick and pack methods:

- Amazon: Amazon uses a combination of batch picking and zone picking to optimize their pick and pack process. They also use automation, such as conveyor belts and robots, to speed up the process. According to a 2023 report by Forbes, this combination has allowed Amazon to handle millions of orders efficiently.

- Zappos: Zappos uses a wave picking method to process their high volume of orders with different product types. They also prioritize employee training and have a strong focus on customer service, resulting in high customer satisfaction rates as reported by Zappos.

- Nordstrom: Nordstrom uses a combination of picking methods and barcoding technology to ensure accuracy and efficiency. They also focus on employee training and implementing best practices, which has helped maintain their reputation for excellent customer service, as highlighted in Retail Dive.

Future Trends in the Pick and Pack Industry

The pick and pack industry is constantly evolving, with new technologies and trends emerging all the time. Here are a few future trends to keep an eye on:

- Robotics: The use of robots in picking and packing is expected to increase, with robots being able to handle more complex tasks and work alongside human workers.

- Artificial intelligence and machine learning: These technologies will help optimize the pick and pack process by providing real-time data analysis and prediction capabilities.

- Augmented reality: Augmented reality technology could be used to guide workers through the picking process, reducing the need for training and potentially speeding up the process.

- Internet of Things (IoT): IoT devices can provide real-time tracking of inventory and equipment, further streamlining the pick and pack process.

- Sustainable packaging: There is a growing trend towards using eco-friendly packaging materials to reduce environmental impact.

Conclusion: The Importance of Choosing the Right Pick and Pack Method

As you can see, there are many factors to consider when choosing the right pick and pack method for your business. By selecting the right method and implementing best practices, you can optimize the process, improve customer satisfaction, and increase profits.