Meeting the Criteria for a Successful Warehouse Center

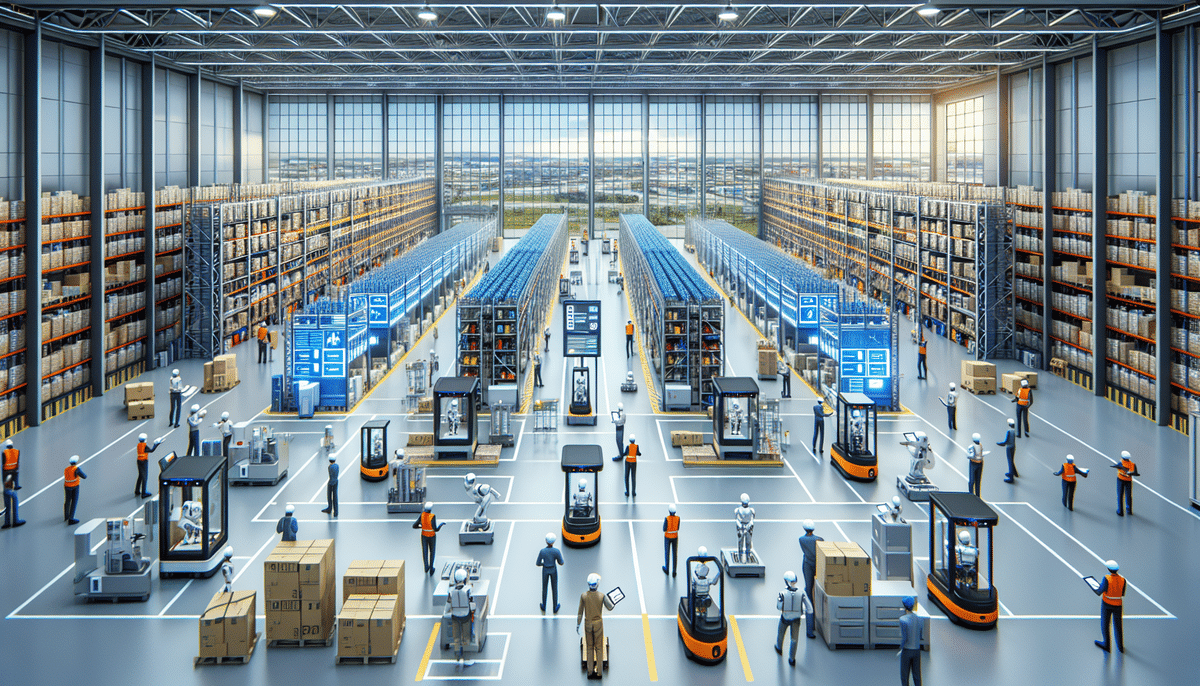

Planning or managing a warehouse center requires meeting specific criteria to ensure its success. From selecting the optimal location and designing an efficient layout to effective staffing and leveraging technology, numerous factors contribute to a thriving warehouse operation. This article delves into each of these components, offering detailed insights and best practices to help you establish a successful warehouse center.

Understanding the Key Components of a Successful Warehouse Center

Before addressing the specific criteria, it's crucial to comprehend the overarching components that define a successful warehouse center. These include:

- Location: Proximity to transportation hubs, suppliers, and customers.

- Layout: Efficient design to optimize workflow and inventory handling.

- Staffing: Hiring and training a capable team.

- Technology Utilization: Implementing advanced systems for inventory and operations.

- Inventory Management: Effective tracking and control of stock levels.

- Clean and Safe Environment: Maintaining workplace safety and hygiene.

- Supplier and Customer Relationships: Building strong partnerships.

- Legal Compliance: Adhering to regulations and standards.

- Performance Metrics: Measuring success through key indicators.

- Overcoming Challenges: Addressing common operational hurdles.

Focusing on each of these areas will set the foundation for running a prosperous warehouse center.

Location, Location, Location: Finding the Right Spot for Your Warehouse

Selecting the ideal location for your warehouse is paramount. Key considerations include:

- Accessibility: Proximity to major highways, railways, and ports to facilitate transportation.

- Proximity to Suppliers and Customers: Reduces lead times and transportation costs.

- Cost Factors: Rental or purchase costs, tax incentives, and local economic conditions.

- Safety: Low crime rates and a stable environment to protect valuable inventory.

- Labor Market: Availability of a skilled workforce and favorable labor laws.

- Future Growth Potential: Room for expansion and infrastructure development.

For instance, according to a 2023 IBISWorld report, logistics hubs near major urban centers have seen a 15% increase in warehouse efficiency due to enhanced transportation links.

Designing Your Warehouse Layout for Optimal Efficiency

An efficient warehouse layout maximizes productivity by minimizing the distance inventory travels. Important factors include:

- Inventory Size and Storage: Tailoring storage solutions (e.g., pallet racks, shelving) to the types of goods handled.

- Equipment Utilization: Incorporating machinery like forklifts and conveyors to streamline operations.

- Space Allocation: Ensuring ample workspace for staff, deliveries, and shipments.

- Technology Integration: Utilizing barcode scanners, automated sorting systems, and Warehouse Management Systems (WMS).

Regularly reviewing and adjusting the layout based on inventory changes and business growth is essential. Implementing Lean principles can further enhance efficiency by eliminating waste and optimizing workflows.

Staffing Your Warehouse: Hiring and Training the Right Team

The success of your warehouse center heavily depends on having a reliable and skilled workforce. Key strategies include:

- Recruitment: Hiring individuals with warehouse experience, attention to detail, and a strong work ethic.

- Training: Providing comprehensive training on equipment use, safety protocols, and inventory systems.

- Work Environment: Fostering a positive workplace culture with opportunities for advancement and competitive compensation.

- Leadership: Establishing a strong management team to guide and support staff.

Implementing a robust inventory management system is crucial for training staff effectively and ensuring seamless operations.

Embracing Technology to Streamline Operations and Improve Productivity

Technology plays a pivotal role in modern warehouse operations by enhancing efficiency and reducing errors. Key technological advancements include:

- Inventory Management Software: Automates tracking of stock levels, orders, and deliveries.

- Barcode and RFID Systems: Improves accuracy in inventory tracking and reduces manual errors.

- Automation and Robotics: Utilizes robots for tasks like sorting, palletizing, and transport, increasing speed and precision.

- Data Analytics: Analyzes operational data to identify trends and areas for improvement.

- Virtual and Augmented Reality: Enhances training programs through immersive simulations.

According to a McKinsey report, warehouses that adopted automation saw a 20% increase in productivity and a 15% reduction in operational costs.

However, it's important to balance technology with human expertise to maintain adaptability and problem-solving capabilities within the workforce.

Inventory Management: Best Practices for Keeping Track of Stock

Effective inventory management is critical for maintaining optimal stock levels and ensuring smooth operations. Best practices include:

- Inventory Management Software: Implement systems to track incoming and outgoing inventory, including location, quantity, and value.

- Regular Audits: Conduct frequent audits to identify and rectify discrepancies.

- Inventory Control Systems: Utilize methods like Just-In-Time (JIT) to manage and optimize stock levels.

- Categorization and Labeling: Use barcodes or RFID tags for accurate tracking and storage.

Organizing inventory efficiently reduces the time needed to locate items and minimizes the risk of stock loss. Implementing cycle counting practices can further enhance accuracy by allowing continuous auditing without disrupting operations.

Maintaining a Clean and Safe Environment in Your Warehouse

A clean and safe warehouse environment is essential for employee well-being and operational efficiency. Key measures include:

- Regular Cleaning: Maintain cleanliness in floors, aisles, and equipment to eliminate hazards.

- Personal Protective Equipment (PPE): Provide necessary PPE to staff and enforce usage.

- Ventilation and Lighting: Ensure adequate ventilation and lighting for a comfortable working environment.

- Safety Protocols: Implement and train staff on safety procedures to prevent accidents.

- Waste Management: Establish proper waste disposal and recycling systems to maintain cleanliness and environmental standards.

Regular safety inspections and encouraging staff to report potential hazards can significantly reduce workplace accidents.

Building Strong Relationships with Suppliers and Customers

Establishing and maintaining robust relationships with suppliers and customers is vital for the sustained success of your warehouse center. Strategies include:

- Clear Communication: Foster transparent communication channels with suppliers to ensure timely deliveries and manage inventory effectively.

- Customer Service: Provide exceptional customer service with fast, accurate shipments and easy return processes.

- Understanding Needs: Listen to feedback from suppliers and customers to tailor services and improve satisfaction.

- Reliability: Consistently meet delivery deadlines and quality standards to build trust and loyalty.

Strong partnerships can lead to long-term collaborations and positive word-of-mouth referrals, enhancing your warehouse's reputation in the industry.

Navigating Legal Requirements and Regulations for Warehouses

Compliance with legal requirements and regulations is essential to avoid penalties and ensure smooth operations. Key areas to address include:

- Safety Regulations: Adhere to Occupational Safety and Health Administration (OSHA) standards and other local safety guidelines.

- Labor Laws: Comply with wage laws, working hours, and employee rights.

- Environmental Regulations: Follow guidelines for waste management, emissions, and sustainability practices.

- Zoning Laws: Ensure your warehouse location is zoned appropriately for storage and distribution activities.

Consulting with legal experts and staying updated on regulatory changes can help maintain compliance and mitigate legal risks.

Measuring Success: Key Metrics to Track and Analyze in Your Warehouse Center

Tracking and analyzing key performance metrics is crucial for assessing the effectiveness of your warehouse operations. Important metrics include:

- Inventory Accuracy: Measures the precision of inventory records compared to actual stock levels.

- Order Processing Time: Tracks the time taken from order receipt to shipment.

- Shipping Accuracy: Monitors the correctness of shipments dispatched to customers.

- Return Rates: Analyzes the frequency and reasons for product returns.

- Cycle Time: Measures the total time to complete a specific process, such as picking or packing.

Utilizing data analytics tools can help identify trends, uncover inefficiencies, and inform strategic decisions to enhance overall warehouse performance.

Common Challenges Faced by Warehouse Owners and How to Overcome Them

Warehouse owners often encounter various challenges that can impede operations. Common issues and solutions include:

- Labor Shortages: Mitigate by offering competitive wages, providing training programs, and utilizing automation to reduce dependency on manual labor.

- Inventory Management Issues: Implement advanced inventory systems and conduct regular audits to maintain accuracy.

- Operational Inefficiencies: Streamline processes through Lean methodologies and technology integration.

- Supply Chain Disruptions: Develop contingency plans and diversify supplier base to handle unexpected disruptions.

- Compliance Challenges: Stay informed about regulatory changes and invest in compliance management systems.

Proactive planning and the adoption of best practices can help overcome these challenges, ensuring the resilience and efficiency of your warehouse operations.

The Future of Warehousing: Trends and Predictions for the Industry

The warehousing industry is continually evolving with advancements in technology and changing market dynamics. Key trends shaping the future include:

- Increased Automation: Greater use of robots and automated systems for tasks like sorting, packing, and inventory management.

- Sustainability Initiatives: Adoption of green practices, such as energy-efficient lighting and sustainable packaging solutions.

- Advanced Data Analytics: Leveraging big data to optimize operations, predict demand, and enhance decision-making.

- Internet of Things (IoT): Implementing IoT devices for real-time tracking and monitoring of inventory and equipment.

- Artificial Intelligence (AI): Utilizing AI for predictive maintenance, demand forecasting, and improving customer service.

- Omni-Channel Fulfillment: Enhancing capabilities to handle multiple sales channels seamlessly, catering to diverse customer needs.

Staying abreast of these trends and integrating relevant technologies can position your warehouse center for future success and competitiveness in the industry.

By adhering to the criteria for a successful warehouse center, you can enhance productivity, reduce operational costs, and deliver exceptional service to your customers. Implement the strategies and best practices discussed in this article to ensure your warehouse center is poised for long-term growth and profitability.