Why Warehouse Locations Are Essential for Businesses

As businesses grow and expand, they often require more space to store their inventory and products. This is where warehouse locations come into play. A warehouse location is a physical site where businesses store their goods, products, and materials for easy access and distribution. In this article, we will discuss the essential role that warehouse locations play in businesses, how they affect supply chain efficiency, and the factors businesses should consider when choosing one.

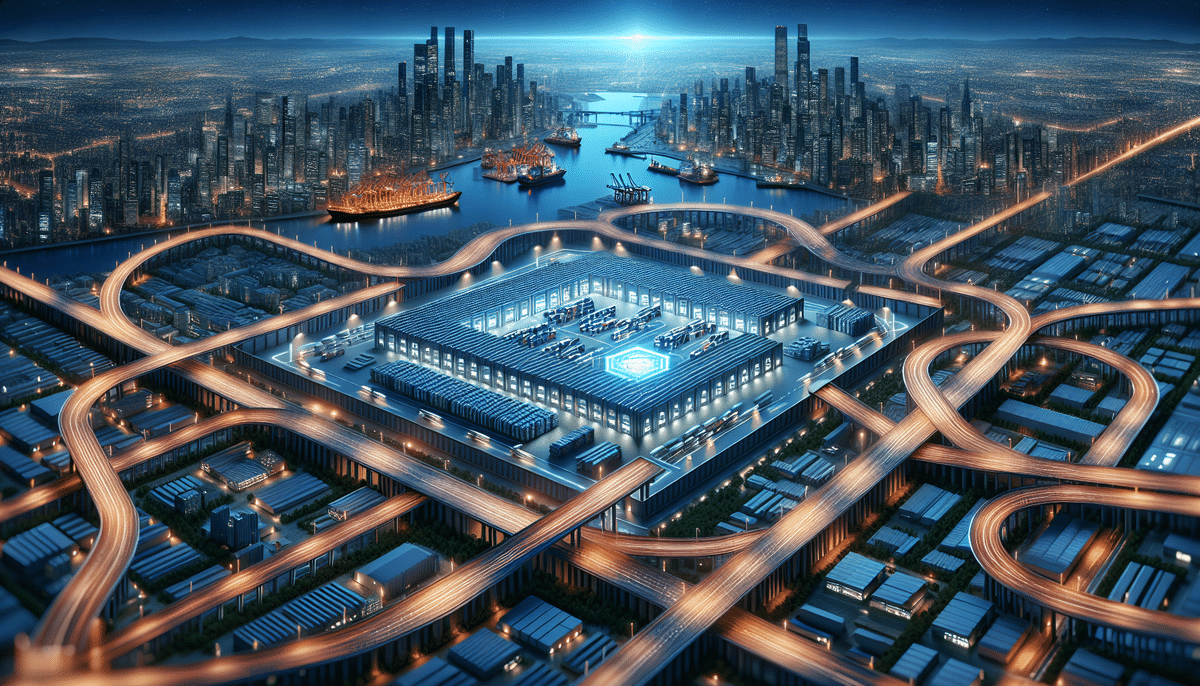

The Role of Warehouse Locations in Business Operations

Warehouse locations are critical to a business's supply chain operations. They help ensure the timely delivery of products to customers and retailers. According to a Supply Chain Digital report, companies can reduce transportation costs by up to 20% by strategically locating their warehouses. A well-placed warehouse can help businesses save both time and money by reducing transportation costs and improving inventory management.

In addition to their logistical benefits, warehouse locations can significantly impact a business's overall sustainability efforts. By strategically placing warehouses closer to customers and suppliers, businesses can reduce their carbon footprint by minimizing transportation distances and emissions. This not only benefits the environment but can also enhance a company's reputation and appeal to environmentally conscious consumers, as reported by GreenBiz.

Furthermore, warehouse locations play a crucial role in disaster preparedness and recovery. By having multiple warehouse locations in different regions, businesses can ensure that their supply chain remains operational even in the event of a natural disaster or other disruptions. This can help minimize the impact on customers and ensure that essential products continue to be delivered in a timely manner, as highlighted by Forrester Research.

How Warehouse Locations Affect Supply Chain Efficiency

The location of a warehouse can significantly affect a business's supply chain efficiency. A well-placed warehouse location can help businesses meet customer demands by improving inventory management, reducing transportation costs, and ensuring supply stability for retailers. For instance, a study by DHL shows that optimal warehouse locations can improve supply chain responsiveness by 30%. Conversely, an inconvenient location can result in inefficient operations and delayed shipments.

When choosing a warehouse location, businesses should consider factors such as proximity to suppliers, transportation infrastructure, and local regulations. For example, a warehouse located near major highways or ports can reduce transportation costs and improve delivery times. Additionally, selecting a location with favorable tax laws or business incentives can provide cost savings and boost profitability. Ultimately, selecting the right warehouse location is crucial for businesses looking to optimize their supply chain and gain a competitive edge in the market.

Factors to Consider When Choosing a Warehouse Location

Choosing the right warehouse location is critical for businesses. Some essential factors to consider include:

- Proximity to transportation hubs: Access to highways, ports, and airports can reduce shipping times and costs.

- Availability of skilled labor: A location with a skilled workforce can improve operational efficiency.

- Local regulations: Understanding zoning laws, permits, and taxes is essential.

- Rent and utilities: Balancing costs with the benefits of the location is key.

- Supply chain and customer needs: Aligning warehouse placement with demand areas ensures timely delivery.

- Type of products: For example, businesses selling perishable goods may need locations closer to consumption areas to ensure product freshness.

Another important consideration is the security of the area. Businesses need to ensure that the warehouse is located in a safe and secure area to prevent theft and damage to their products. This can be achieved by researching crime rates in the area and investing in security measures such as surveillance cameras, alarms, and security personnel. Additionally, businesses should consider the risk of natural disasters such as floods, earthquakes, and hurricanes when choosing a warehouse location, and take necessary precautions to protect their products.

The Impact of Warehouse Location on Customer Satisfaction

The location of a business's warehouse directly affects its ability to meet customer demands. A well-placed warehouse location can ensure faster shipping times and higher order fulfillment rates, ultimately leading to increased customer satisfaction. In today's consumer-driven market, where fast delivery times are increasingly critical, a well-placed warehouse location can mean the difference between a satisfied customer and a lost sale.

However, choosing the right warehouse location is not just about proximity to customers. Other factors, such as transportation infrastructure, labor availability, and real estate costs, also play a crucial role. For example, a warehouse located near a major highway or airport can facilitate faster and more efficient transportation of goods, while a location with a high concentration of skilled workers can help ensure a reliable and competent workforce.

Moreover, the impact of warehouse location on customer satisfaction extends beyond shipping times and order fulfillment rates. A strategically located warehouse can also help businesses reduce their carbon footprint by minimizing transportation distances and optimizing delivery routes, enhancing environmental sustainability and appealing to environmentally conscious customers.

The Benefits of Choosing a Centralized Warehouse Location

Choosing a centralized warehouse location can provide several benefits for businesses:

- Simplified supply chain management: Centralized locations make it easier to oversee and coordinate operations.

- Reduced transportation costs: Central locations can minimize travel distances to various markets.

- Improved inventory management: Centralized warehousing allows for more efficient tracking and replenishment.

- Access to a larger labor pool: Central locations typically have a more extensive and diverse pool of potential employees.

- Enhanced order fulfillment speed: Quick access to inventory enables timely order processing.

- Greater flexibility and agility: Centralized warehouses can quickly adjust inventory levels and distribution strategies in response to market changes.

Additionally, centralized warehouse locations can provide businesses with greater flexibility and agility in responding to changes in the market. By having a centralized location, businesses can quickly adjust their inventory levels and distribution strategies to meet changing customer demands and market conditions, helping them stay competitive and profitable in the long run.

The Advantages and Disadvantages of Rural vs Urban Warehouse Locations

Choosing between a rural or urban warehouse location can be a tough decision for businesses. Rural warehouse locations can provide larger facilities at lower prices, along with access to readily available land for future expansion. However, they may be farther from major transportation hubs and markets.

On the other hand, urban warehouse locations offer better access to transportation hubs and labor, which can help improve supply chain efficiency. However, they often come with higher real estate costs and potentially higher competition. A proper analysis of specific business needs, goals, and target market is essential when deciding between rural and urban locations.

Another factor to consider is the level of competition in the area. Urban areas tend to have more competition, which can drive up prices and make it harder for businesses to stand out. In contrast, rural areas may have less competition, but may also have a smaller customer base. Businesses should weigh the pros and cons of each location and consider their long-term growth strategy before making a decision.

The Importance of Proximity to Transportation Hubs in Warehouse Location

Proximity to transportation hubs is crucial when choosing a warehouse location. A well-placed warehouse can provide easy access to shipping ports, airports, railways, and highways, improving supply chain efficiency and reducing transportation costs. According to Statista, logistics costs account for approximately 8% of the total cost of goods sold, highlighting the importance of strategic location planning.

Businesses should consider the location's proximity to transportation hubs to ensure faster delivery times, ultimately leading to satisfied customers and retailers. In addition to faster delivery times and reduced transportation costs, proximity to transportation hubs can also provide businesses with access to a wider range of transportation options. For example, a warehouse located near a shipping port can easily transport goods overseas, while a warehouse near a railway can transport goods across the country. This flexibility in transportation options allows businesses to adapt to changing market demands and expand their customer base.

The Effect of Local Regulations on Choosing a Warehouse Location

Local regulations can significantly impact a business's decision when choosing a warehouse location. Businesses should consider local zoning laws, permits, infrastructure, and taxes, as these factors can affect the costs associated with operating a warehouse. Understanding local regulations is essential before selecting a warehouse location to avoid unforeseen expenses and operational hurdles.

One important consideration is the availability of labor. Regulations related to labor laws, minimum wage, and worker safety can vary significantly between locations. Businesses should research the local labor market to ensure they can find and retain qualified workers willing to operate under the local regulations. For instance, stricter labor laws in some regions may increase operational costs but ensure higher worker satisfaction and retention.

Another factor is the potential for future changes in local regulations. Businesses should evaluate the political climate and the likelihood of changes to regulations that could impact their operations. This includes changes to tax laws, environmental regulations, or zoning laws. By staying informed about potential changes, businesses can make more informed decisions about where to locate their warehouse.

The Impact of Technology on Modern Warehouse Locations

Advancements in technology have significantly impacted modern warehouse locations. The use of automation and robotics has improved supply chain efficiency and inventory management. According to McKinsey, automation can increase warehouse productivity by up to 30%. Additionally, the implementation of real-time tracking and predictive analytics has enhanced inventory accuracy and reduced waste.

Emerging technologies such as the Internet of Things (IoT), artificial intelligence (AI), and machine learning are further transforming warehouse operations, enabling businesses to optimize their warehouse locations' efficiency and adapt to changing market demands. It is essential for businesses to keep up with the latest technological innovations to remain competitive and improve their warehouse operations' efficiency.

How to Optimize Your Warehouse Layout for Maximum Efficiency

The layout of a warehouse is crucial for maximizing efficiency. Businesses should consider:

- Placement of storage racks: Optimize space utilization and accessibility.

- Design of aisles: Ensure sufficient space for equipment and reduce bottlenecks.

- Location of receiving and shipping areas: Streamline the flow of goods into and out of the warehouse.

By optimizing the warehouse layout, businesses can improve inventory management, reduce transportation costs within the warehouse, and enhance overall supply chain efficiency. Implementing technologies such as warehouse management systems (WMS) and utilizing data-driven insights can further aid in creating an efficient warehouse layout.

Best Practices for Managing Multiple Warehouse Locations

Managing multiple warehouse locations can be challenging for businesses. Some best practices include:

- Implementing real-time tracking and inventory management systems: Provides visibility across all locations.

- Standardizing procedures: Ensures consistency in operations across all warehouses.

- Regularly monitoring and analyzing performance data: Identifies areas for improvement and optimizes operations.

By following these best practices, businesses can effectively manage multiple warehouse locations, ensuring that each operates efficiently and contributes to the overall supply chain performance. Utilizing centralized software platforms and fostering communication between locations can also enhance management effectiveness.

Future Trends in the Evolution of Warehouse Locations and Logistics

The future of warehouse locations and logistics is rapidly evolving due to advancements in technology, eCommerce growth, and changes in transportation. Some trends to watch for include:

- Drones for delivery: Increasingly used for last-mile delivery, reducing delivery times.

- Augmented reality (AR) in warehouse operations: Enhances worker training and improves picking accuracy.

- Environmentally sustainable warehousing: Includes green buildings and supply chain optimization to reduce carbon footprint.

These trends are reshaping the logistics landscape, offering businesses opportunities to enhance efficiency, reduce costs, and meet evolving customer expectations.

Conclusion

In conclusion, warehouse locations play an essential role in businesses' supply chain operations. Choosing the right warehouse location can significantly impact a business's bottom line by improving supply chain efficiency, reducing transportation costs, and meeting customer demands effectively. Businesses should carefully consider several factors when selecting a warehouse location, such as local regulations, proximity to transportation hubs, and supply chain and customer needs. Adopting best practices for warehouse management, staying abreast of technological advancements and future trends, and continuously optimizing warehouse layouts can help businesses remain competitive and improve overall efficiency.