Ensuring Warehouse Safety in Q4: Tips and Best Practices

As the busy holiday season approaches, warehouses worldwide are gearing up for increased activity and demand. This surge in operations, however, elevates the risk of accidents and injuries. Ensuring warehouse safety during Q4 is crucial and requires a comprehensive approach that includes safety equipment, training, regular inspections, and fostering a safety culture. In this article, we explore common safety hazards during this busy season, relevant safety regulations and standards, essential safety equipment for warehouse workers, and best practices for inventory management to enhance safety.

Why Q4 Safety is Important for Warehouses

During Q4, warehouses experience heightened activity compared to the rest of the year. The increased pace can complicate operations management and safety oversight. Additionally, handling larger inventories during the holiday season ramps up traffic levels, heightening the likelihood of accidents. According to the [Occupational Safety and Health Administration (OSHA)](https://www.osha.gov/), warehouse accident rates can increase by up to 30% during peak seasons. Therefore, companies must proactively ensure Q4 safety in their warehouses.

Common Safety Hazards in Warehouses During Q4

During the holiday season, warehouses may face a range of safety hazards, including:

- Slips and falls caused by wet floors or cluttered environments resulting from increased activity

- Forklift accidents

- Workplace fires caused by flammable or combustible materials in inventory

- Overexertion and fatigue

- Chemical exposure

- Repetitive motion injuries, such as carpal tunnel syndrome, due to extended production hours

Safety Regulations and Standards for Warehouses in Q4

There are comprehensive laws and regulations that set safety standards for warehouses, including those specific to Q4. Key standards include [OSHA regulations](https://www.osha.gov/laws-regs), the International Building Code, and various state and local jurisdictions. It is advisable for companies to review OSHA regulations specific to warehouses and ensure they are fulfilling their legal obligations on workplace health and safety. This involves conducting regular inspections, maintaining records of potential hazards, and partnering with OSHA to stay updated on best practices and resources.

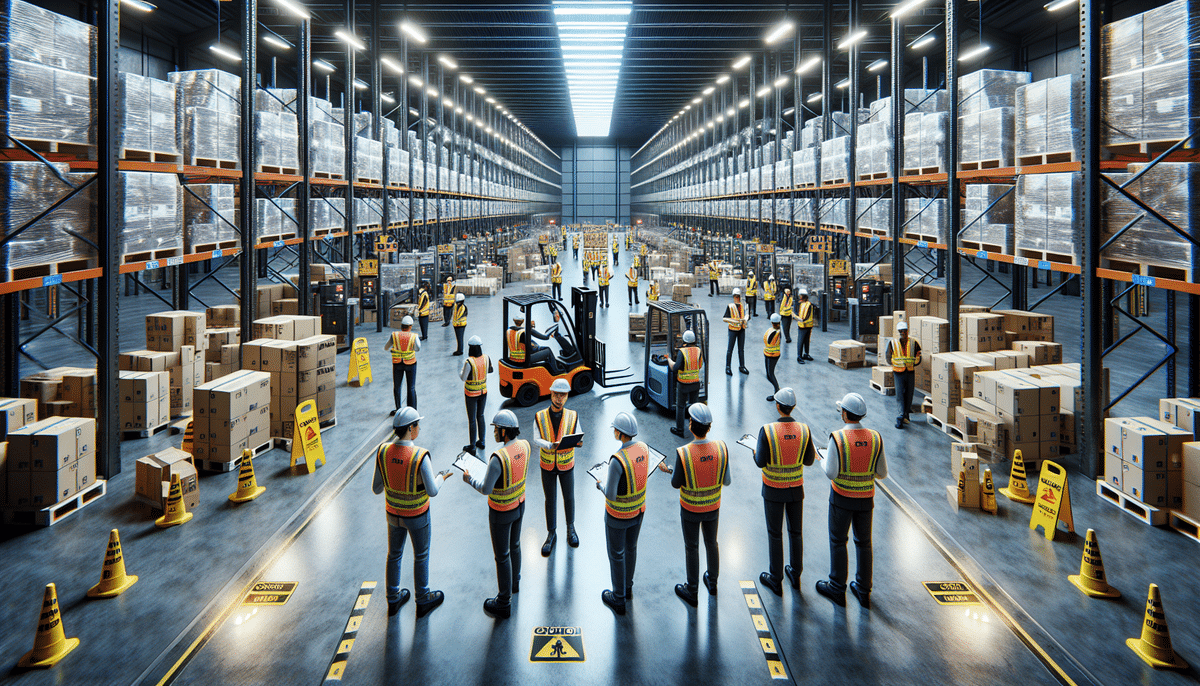

Essential Safety Equipment for Warehouse Workers in Q4

Employers should invest in the right safety equipment to ensure that their workers are comfortable and safe during Q4 operations. Some essential safety equipment includes:

- Protective gloves, suits, and eye protection to guard against chemical exposure and other hazards

- Safety vests and helmets for workers operating in high-traffic areas

- Heat stress gear for workers exposed to high temperatures

- Hearing protection or earplugs for those working near loud machinery

- Work gloves for frequent material handling

- A well-stocked first aid kit for immediate injury response

Additionally, companies should develop an emergency response plan outlining steps to take in case of accidents or emergencies, including proper equipment usage.

Training and Education for Warehouse Workers on Safety in Q4

Ensuring that workers are adequately trained before Q4 operations is vital. Training should cover:

- Safety protocols and procedures

- Proper use of equipment and safety gear

- Hazardous material handling techniques

- Emergency response protocols

- Warehouse traffic rules and regulations

Ongoing training with regular updates is essential as standards and protocols evolve. Offering refresher courses can help workers stay informed about best practices and maintain confidence in their roles.

Establishing a Safety Culture in Your Warehouse During Q4

Fostering a safety culture ensures that all workers prioritize safety during Q4. This can be achieved by:

- Regularly communicating safety issues and protocols with employees

- Establishing safety committees comprising workers and management to address emerging issues

- Offering incentives for adhering to safety practices

- Encouraging workers to report safety concerns to supervisors or managers

A strong safety culture promotes collective responsibility for maintaining a safe working environment.

Conducting Regular Inspections to Ensure Warehouse Safety in Q4

Regular inspections are critical to ensure adherence to safety protocols and to identify potential hazards before they cause accidents. Inspections should include:

- Checking machinery and equipment for defects or damage

- Assessing flooring for hazards such as wet spots or obstructions

- Verifying that emergency exits are unobstructed and functional

Following inspections, employers should address identified issues promptly and conduct safety training and communication to reinforce best practices.

Identifying and Addressing Potential Hazards in Your Warehouse during Q4

Proactively identifying and addressing potential hazards helps prevent accidents and injuries. This involves:

- Regularly inspecting for hazards like hanging wires or faulty equipment

- Implementing protocols to mitigate identified risks

- Conducting training sessions to educate workers on hazard recognition and prevention

The goal is to eliminate risks before they result in incidents, thereby maintaining a safe working environment.

Ensuring Fire Safety in Your Warehouse During the Busy Holiday Season

The increased handling of flammable and combustible materials during the holiday season heightens fire risks. To ensure fire safety:

- Install and maintain accessible fire extinguishers

- Ensure that fire alarm systems are functional and regularly inspected

- Implement a strict no-smoking policy within the warehouse

- Develop and train workers on fire safety protocols and evacuation procedures

These measures help prevent fires and ensure a swift response if one occurs.

Best Practices for Managing Inventory to Enhance Warehouse Safety during Q4

Effective inventory management can significantly enhance warehouse safety during the holiday season. Best practices include:

- Organizing products to prevent disorganization and reduce accident risks

- Avoiding the accumulation of combustible materials

- Maintaining proper inventory levels to prevent overloading shelves and storage units

- Establishing separate storage areas for hazardous materials with appropriate safety protocols

Proper inventory management not only improves safety but also boosts efficiency and reduces worker fatigue.

Importance of Regular Maintenance and Repairs of Equipment and Facilities in Ensuring Warehouse Safety during Q4

Regular maintenance and timely repairs of warehouse equipment and facilities are paramount for safety during Q4. This includes:

- Inspecting and repairing conveyor belts and mechanical devices

- Checking the structural integrity of warehouse roofs and buildings

- Ensuring that all safety equipment is functioning correctly

Neglecting maintenance can lead to machinery malfunctions, falls, and other serious injuries.

Tips for Reducing Workplace Accidents and Injuries During the Busy Holiday Season

To minimize workplace accidents and injuries during the holiday rush, consider the following tips:

- Develop a training program that emphasizes critical safety protocols

- Establish a safety committee for continuous safety improvements

- Provide adequate rest periods to prevent worker fatigue

- Ensure all equipment is well-maintained and handled properly

- Conduct regular warehouse assessments to identify and mitigate hazards proactively

- Equip workers with the necessary safety gear for their tasks

Implementing these strategies can help maintain a safe warehouse environment during the busiest times of the year.

How Technology Can Improve Warehouse Safety During Q4

Leveraging innovative technology can significantly enhance warehouse safety during Q4. Technologies to consider include:

- IoT-based sensors for real-time hazard detection

- Automated machines, robots, and drones to handle repetitive or dangerous tasks

- e-Learning platforms for ongoing safety training and education

These technologies not only help in monitoring and preventing hazards but also allow human workers to focus on more critical and less hazardous tasks.

Creating an Emergency Response Plan to Ensure Quick Response to Accidents or Emergencies during Q4

Developing a comprehensive emergency response plan is essential for a swift reaction to accidents or emergencies during Q4. The plan should include:

- Defining what constitutes an emergency

- Steps to take if someone is injured

- Evacuation procedures in case of fire or other threats

- Protocols for handling chemical spills, including isolation, communication with emergency services, and decontamination

Regularly reviewing and updating the emergency response plan ensures its effectiveness and relevance.

Benefits of Prioritizing Employee Health and Wellness Programs to Enhance Warehouse Safety during the Holiday Season

Prioritizing employee health and wellness is integral to maintaining warehouse safety during Q4. Health and safety programs can:

- Promote healthy work practices and habits

- Reduce fatigue and the likelihood of accidents

- Build resilience and productivity among workers

- Offer incentives for maintaining healthy lifestyles and adhering to safety protocols

Such programs contribute to a more engaged and safety-conscious workforce.

How Partnerships with OSHA Can Enhance Your Company's Commitment to Fulfilling Its Legal Obligations on Workplace Health and Safety

Forming partnerships with [OSHA](https://www.osha.gov/) can greatly benefit both companies and employees. These partnerships provide:

- Technical assistance, training, and consultations on workplace safety

- Guidance on fulfilling legal safety obligations

- Access to the latest research and safety resources

- Potential reductions in OSHA inspections for companies that demonstrate significant safety improvements

For workers, OSHA partnerships ensure safer working conditions through enhanced safety measures and reduced workplace accidents.

Common Mistakes to Avoid When Ensuring Warehouse Safety during the Busy Holiday Season

When aiming to ensure warehouse safety during the busy holiday season, it's crucial to avoid the following mistakes:

- Setting unrealistic work schedules and productivity goals that compromise safety

- Neglecting regular inspections, training, and communication regarding safety protocols

- Overlooking the importance of maintenance and repairs of equipment and facilities

- Failing to address identified safety hazards promptly

Avoiding these pitfalls is essential for maintaining a safe and efficient warehouse environment during peak seasons.

Measuring the Effectiveness of Your Health and Safety Strategies: Key Metrics to Track During Q4

To evaluate the effectiveness of your warehouse's health and safety strategies, track the following key metrics:

- Injury and accident rates and their trends over time

- Workers' willingness to report potential hazards and safety concerns

- Response times to emergency situations

- Recognition and awards received for exemplary safety protocol implementation

- Insurance premium costs related to workplace incidents

Monitoring these metrics allows companies to assess progress, identify areas for improvement, and ensure that safety goals are being met.

Conclusion: Steps You Can Take Today to Ensure Safe Operations in Your Warehouse this Q4 Season!

Ensuring warehouse safety during Q4 is essential for creating a secure working environment for employees. Key steps to take include:

- Conducting regular inspections to identify potential hazards

- Investing in essential safety equipment to protect workers

- Building a safety culture to enhance safety awareness

- Implementing comprehensive training programs on safety protocols and procedures

- Managing inventory carefully to prevent accidents and ensure efficiency

Employers who prioritize these measures can foster safe work environments, prioritize employee health and safety, and ultimately achieve greater productivity and long-term success.