What is a Floor Loaded Container?

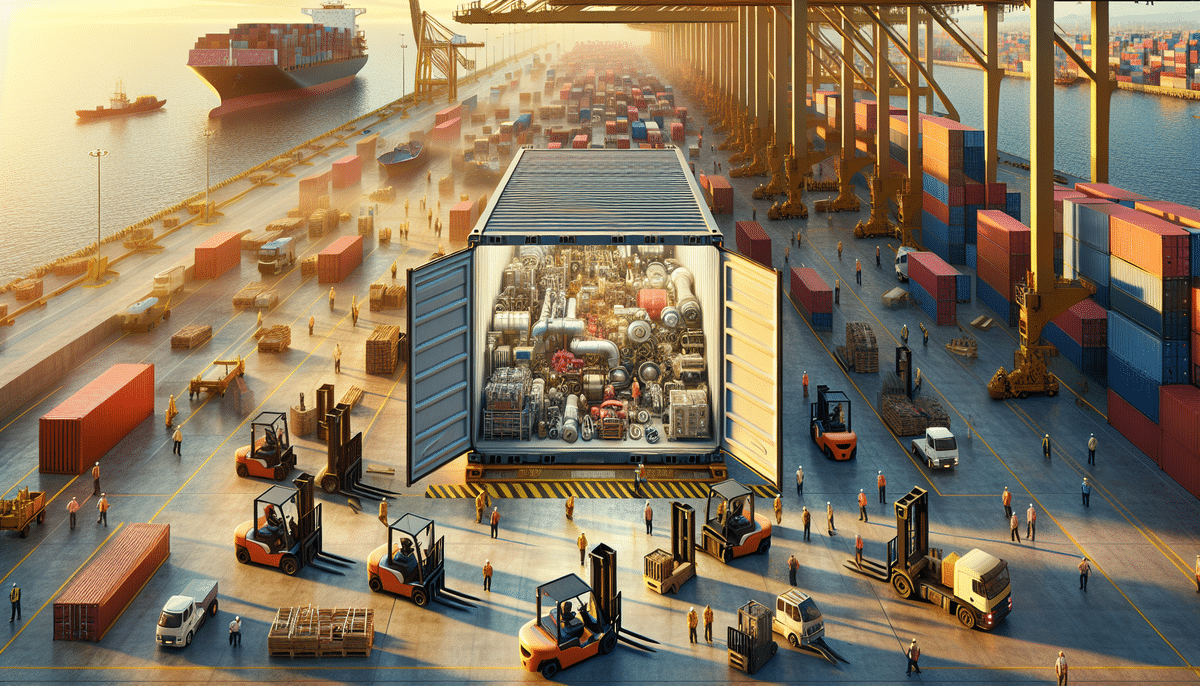

A floor loaded container is a specialized type of shipping container designed to be loaded directly from the floor, rather than using pallets. This design is ideal for transporting heavy or oversized items that cannot be easily placed on pallets, such as machinery, pipes, barrels, and furniture. Typically constructed from steel, floor loaded containers come in various sizes and capacities to meet the diverse needs of shippers.

Understanding the Basics of Floor Loaded Containers

Floor loaded containers are essentially robust rectangular boxes with a single open end. The container's floor is reinforced with steel or aluminum to support the weight of heavy and bulky cargo. The sides and top are usually made of corrugated steel panels, providing structural strength and protection during transit. Common sizes for these containers include 20-foot and 40-foot lengths, although custom sizes are available to accommodate specific shipping requirements.

When loading a floor loaded container, it is crucial to:

- Distribute the weight evenly to prevent damage to both the container and the cargo.

- Secure the cargo properly to avoid shifting during transportation.

- Use appropriate loading techniques for different types of items.

Floor loaded containers are widely used in industries such as construction, manufacturing, and automotive, where transporting heavy machinery, vehicles, and large components is common.

Benefits of Using Floor Loaded Containers

Floor loaded containers offer numerous advantages for shippers:

- Enhanced Heavy Cargo Support: These containers are reinforced to handle heavier loads compared to standard containers.

- Cost Efficiency: Eliminating the need for pallets reduces shipment costs.

- Minimized Damage: Direct floor loading allows for a more secure arrangement of cargo, reducing the risk of shifting and damage during transit.

- Flexibility in Cargo Size and Shape: Without pallets, cargo can be loaded in various configurations, accommodating odd-shaped or oversized items more easily.

- Efficient Loading and Unloading: The absence of pallets simplifies the loading process, saving time and reducing labor costs.

According to the 2023 Logistics Report, floor loaded containers have seen a 15% increase in usage among manufacturing firms due to their superior adaptability and cost-saving benefits.

What Industries Use Floor Loaded Containers?

A wide range of industries utilize floor loaded containers, including:

- Manufacturing: Transporting heavy machinery and large components.

- Automotive: Shipping vehicles and automotive parts.

- Construction: Moving construction materials like bricks, cement, and steel beams.

- Agriculture: Transporting bulk crops such as fruits and vegetables directly from the field.

- Furniture: Shipping large or bulky furniture items without the need for disassembly.

These industries benefit from the versatility and strength of floor loaded containers, allowing for the efficient and safe transportation of a variety of goods.

How to Load a Floor Loaded Container

Proper loading of a floor loaded container is essential to maximize space and ensure the safety of the cargo. Follow these steps for optimal loading:

- Prepare the Container: Ensure the container floor is clean, smooth, and level to provide a stable base for the cargo.

- Plan the Layout: Arrange items to optimize space usage, placing larger and heavier items first.

- Distribute Weight Evenly: Position heavier items towards the center to maintain balance and prevent undue strain on the container walls.

- Secure the Cargo: Use ratchet straps, tie-downs, or other restraints to secure items and prevent movement during transit.

- Protect Fragile Items: Use cushioning materials like bubble wrap or foam to protect delicate goods from impact.

- Monitor Environmental Conditions: For sensitive items, ensure the container is equipped with temperature and humidity control systems.

Tips for Maximizing Space in a Floor Loaded Container

Efficient use of space in a floor loaded container can lead to significant cost savings. Consider the following strategies:

- Puzzle-Packing: Arrange odd-shaped items like pieces of a puzzle to fill gaps and maximize space utilization.

- Stacking: Tightly stack items while ensuring even weight distribution to optimize vertical space.

- Strategic Weight Placement: Place lightweight items on top of heavier ones to balance the overall weight.

- Use of Dunnage: Implement airbags or dunnage bags to fill gaps and prevent shifting.

- Pallets and Skids: Utilize pallets or skids to facilitate stacking and organization, enhancing space efficiency.

By applying these techniques, shippers can fully leverage the container's capacity, reducing the number of shipments required and lowering transportation costs.

Types of Products Suitable for Floor Loading

Floor loaded containers are ideal for transporting a diverse range of products, including:

- Automotive parts and vehicles

- Furniture and appliances

- Heavy machinery and industrial equipment

- Pipes and storage tanks

- Construction materials like bricks, cement, and steel beams

These containers are particularly beneficial for shipping odd-shaped or oversized items that do not conform to standard pallet configurations, providing a versatile solution for various industries.

How to Choose the Right Size of a Floor Loaded Container

Selecting the appropriate size of a floor loaded container is crucial for efficient shipping. Consider the following factors:

- Dimensions and Weight of Cargo: Measure the size and weight of all items to determine the necessary container capacity.

- Mode of Transportation: Ensure the container size complies with legal regulations for road运输 or is compatible with shipping lines for sea transport.

- Cost Implications: Balance the size of the container with transportation costs, opting for a size that minimizes total expenses.

For instance, a 40-foot container may offer more space for bulkier items, but a 20-foot container might be more cost-effective for smaller shipments. Assessing these factors helps businesses choose the most suitable container size for their specific needs.

Safety Considerations When Using Floor Loaded Containers

Ensuring safety is paramount when handling floor loaded containers. Key considerations include:

- Proper Training: Workers should be trained in safe loading and unloading practices to prevent injuries.

- Securement of Cargo: Use appropriate restraints to keep cargo stable and prevent shifting during transit.

- Weight Distribution: Evenly distribute weight within the container to avoid tipping or structural damage.

- Regular Inspections: Inspect containers for structural integrity and ensure they are free from defects.

Adhering to these safety measures reduces the risk of accidents, protects valuable cargo, and minimizes liability and additional costs associated with damaged goods.

Cost-Effective Shipping with Floor Loaded Containers

Floor loaded containers can significantly reduce transportation costs for businesses by:

- Maximizing Space Utilization: Efficient packing reduces the number of containers needed, lowering shipping expenses.

- Eliminating Pallet Costs: Direct floor loading removes the need for pallets, resulting in immediate cost savings.

- Reducing Labor Costs: Streamlined loading and unloading processes decrease the time and labor required.

- Minimizing Damage: Secure cargo handling reduces the likelihood of damage, avoiding costly replacements or repairs.

According to industry data, companies utilizing floor loaded containers have reported up to a 20% reduction in shipping costs compared to traditional pallet-based methods.

Innovations and Advancements in the Field of Floor Loaded Containers

The design and functionality of floor loaded containers continue to evolve with technological advancements:

- Enhanced Safety Features: Incorporation of locking mechanisms and reinforced structures to improve cargo stability.

- Smart Containers: Integration of IoT devices for real-time tracking and monitoring of environmental conditions.

- Modular Designs: Flexible interior configurations that allow for easy customization based on cargo requirements.

- Eco-Friendly Materials: Use of sustainable materials and energy-efficient manufacturing processes.

These innovations enhance the reliability, efficiency, and sustainability of floor loaded containers, providing shippers with more effective solutions for their transportation needs.

Common Mistakes to Avoid When Using a Floor Loaded Container

To ensure successful shipping with floor loaded containers, avoid the following common mistakes:

- Poor Packing Techniques: Failing to arrange cargo properly can lead to wasted space and increased risk of damage.

- Inadequate Securing of Cargo: Not using sufficient restraints can result in shifting items during transit.

- Ignoring Weight Distribution: Uneven weight can cause container instability and potential tipping.

- Overloading the Container: Exceeding weight limits can compromise container integrity and lead to safety hazards.

- Neglecting Environmental Controls: Failing to maintain proper temperature and humidity levels for sensitive goods.

Awareness and prevention of these mistakes ensure safe and cost-effective transportation of goods using floor loaded containers.

Differences Between Regular and Floor Loaded Containers

The primary distinction between floor loaded containers and regular shipping containers lies in their loading methods:

- Floor Loaded Containers: Loaded directly from the floor without the use of pallets, allowing for greater flexibility in cargo size and shape.

- Regular Containers: Utilize standard-sized pallets for loading, which can limit the types and arrangements of cargo.

Consequently, floor loaded containers offer maximized space utilization and are better suited for irregular or oversized items, whereas regular containers are ideal for palletized shipments that conform to standard dimensions.

Comparison of Different Types of Container Loading Techniques

Several container loading techniques are available, each with its own set of advantages:

- Standard Pallet Loading: Uses uniform pallets for easy stacking and handling, suitable for consistent and palletized cargo.

- Rack Loading: Employs racks to organize and secure cargo, ideal for larger or heavier items that need additional support.

- Slip-Sheet Loading: Utilizes slip-sheets instead of pallets, offering a lightweight alternative for stacking goods.

- Roll-On/Roll-Off (RoRo) Loading: Designed for wheeled cargo like vehicles, allowing easy loading and unloading without traditional container handling.

- Floor Loading: Directly loads cargo onto the container floor, providing maximum flexibility for various shapes and sizes.

Each method caters to different shipping needs, with floor loading being particularly advantageous for irregular, bulky, or heavy items that do not fit standard pallet configurations.

Conclusion

Floor loaded containers present a practical and cost-effective solution for shipping heavy and oversized cargo. By employing proper loading techniques and adhering to safety protocols, businesses can maximize container space, reduce transportation costs, and ensure the safe delivery of goods. Advancements in container design and technology continue to enhance the efficiency and versatility of floor loaded containers, making them an increasingly popular choice across various industries. Companies looking to optimize their shipping operations should consider the benefits of floor loaded containers and implement best practices to leverage their full potential.