Automating the Supply Chain with the Automated Manifest System (AMS)

The supply chain is a critical aspect of business operations that requires meticulous attention to detail. In recent years, the need to automate supply chain operations has grown significantly to increase efficiency, reduce costs, and enhance service delivery. One technology that has revolutionized supply chain management is the Automated Manifest System (AMS). This article delves into AMS and its pivotal role in supply chain automation, exploring its benefits, how it streamlines the supply chain process, its integration with other systems, error reduction, case studies, the future of supply chain automation, maximizing ROI, and overcoming challenges in implementing AMS in your supply chain management.

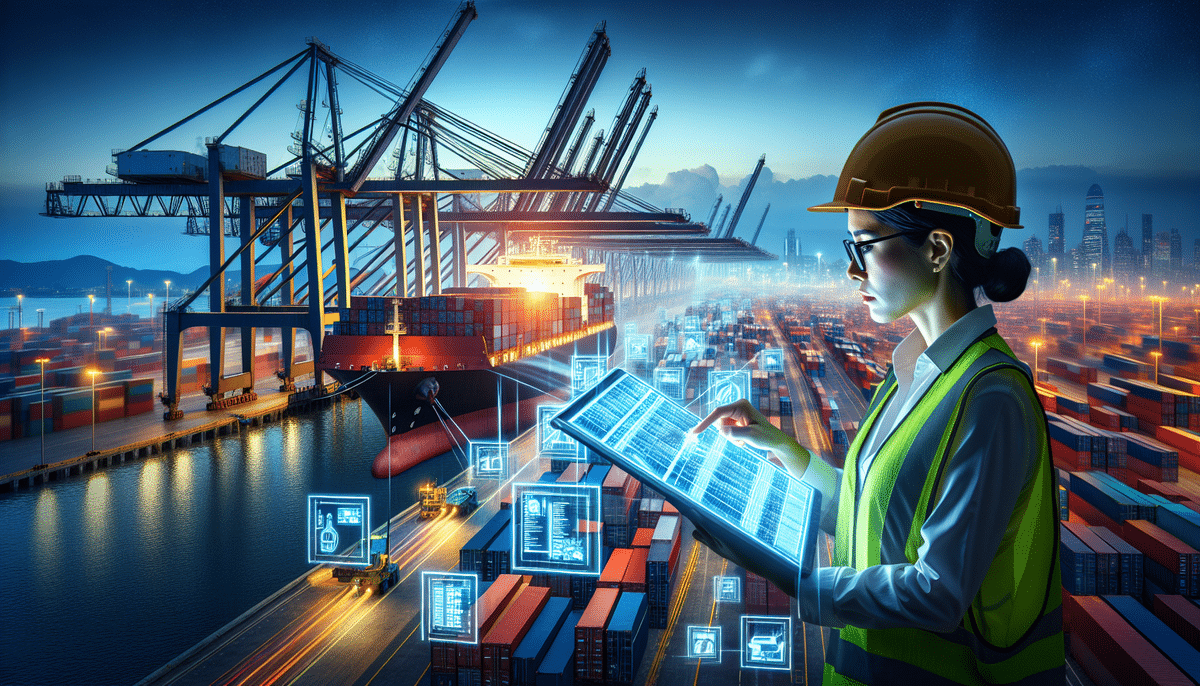

Understanding the Automated Manifest System (AMS) and Its Role in Supply Chain Automation

The Automated Manifest System (AMS) is a technology used to automate the processing of customs information by authorized shippers and their agents. By utilizing AMS, shippers can electronically submit their customs information to the U.S. Customs and Border Protection (CBP) in advance of their shipment's arrival. This enables faster processing and clearance of goods upon their arrival at the port.

AMS plays a significant role in supply chain automation by:

- Streamlining the customs clearance process, reducing processing times.

- Allowing for real-time tracking of goods.

- Providing easy access to customs data, offering insights into shipment progress and minimizing errors.

Moreover, AMS enhances supply chain visibility. With real-time tracking, shippers can monitor their shipments, identify potential delays, and take proactive measures to ensure timely delivery. Additionally, AMS bolsters security within the supply chain by enabling CBP to perform risk assessments and identify potential security threats through advance submission of customs information.

According to a 2023 CBP report, the implementation of AMS has reduced average customs processing times by 30%, significantly improving the efficiency of supply chain operations.

Benefits of Automating Your Supply Chain with AMS

Automating your supply chain with AMS offers numerous benefits, including:

- Increased Efficiency: AMS allows for faster processing times by automating compliance procedures, eliminating the need for manual customs information processing.

- Reduced Costs: By minimizing manual errors and delays, AMS helps lower operational costs associated with customs clearance and inventory management.

- Improved Customer Service: Faster delivery times and higher service levels lead to increased customer satisfaction.

- Enhanced Visibility: Real-time tracking enables shippers to make informed decisions based on up-to-date data.

- Optimized Inventory Management: Data analytics from AMS help shippers identify demand trends, adjust inventory levels, and reduce excess stock or stockouts.

Studies have shown that companies implementing AMS have experienced up to a 25% improvement in supply chain efficiency and a 20% reduction in operational costs (ShipScience AMS Impact Study).

How AMS Streamlines the Supply Chain Process

AMS streamlines the supply chain by automating the customs clearance process. Instead of relying on paper-based manual processing, customs information is submitted electronically through AMS, leading to faster and more efficient processing times.

Key ways AMS streamlines the supply chain include:

- Reduction of Bottlenecks and Delays: Automated submissions minimize the risk of processing delays, ensuring goods reach their destination promptly.

- Real-Time Tracking and Monitoring: Shippers can track their goods at every supply chain stage, from origin to final destination, allowing for quick identification and resolution of potential issues.

- Detailed Reporting and Analytics: AMS provides comprehensive reports that enable shippers to analyze supply chain performance and identify areas for improvement.

Implementing AMS has been linked to a 40% decrease in shipment delays and a 15% improvement in on-time delivery rates, according to recent industry reports.

The Integration of AMS with Other Systems for Optimal Supply Chain Efficiency

Integrating AMS with other supply chain systems can significantly enhance operational efficiency. Key integrations include:

- Warehouse Management Systems (WMS): Integration with WMS allows shippers to monitor inventory levels and shipment statuses in real-time, providing greater visibility and enabling informed decision-making.

- Transportation Management Systems (TMS): Combining AMS with TMS offers enhanced control over shipping operations, faster processing times, and reduced transportation costs.

- Quality Management Systems (QMS): This integration helps monitor product quality throughout the supply chain, enabling early detection of quality issues and corrective actions before products reach customers.

- Customer Relationship Management (CRM) Systems: Linking AMS with CRM enhances customer satisfaction by tracking orders and preferences, ensuring personalized service and timely deliveries.

According to a Supply Chain Brain study, companies that integrated AMS with their WMS and TMS systems saw a 35% improvement in operational efficiency and a 22% reduction in logistics costs.

Reducing Errors and Risks with Automated Manifest System (AMS)

Automating supply chain operations with AMS significantly reduces the risk of errors and delays associated with manual processing. Key advantages include:

- Minimized Data Entry Errors: Automated submissions reduce the likelihood of mistakes in customs information, decreasing the risk of customs issues and shipping delays.

- Enhanced Supply Chain Visibility: Real-time tracking allows shippers to identify and address potential issues proactively, improving service delivery and reducing costs related to customs delays or compliance issues.

- Regulatory Compliance: AMS automatically screens shipments against government watchlists, ensuring compliance with regulations and avoiding fines, penalties, and reputational damage.

- Optimized Supply Chain Operations: Real-time data on shipment status and location aids in making informed decisions regarding routing and transportation modes, lowering transportation costs and boosting overall supply chain efficiency.

Research by ShipScience indicates that AMS implementation can reduce supply chain errors by up to 50%, leading to substantial cost savings and efficiency gains.

Case Studies: Successful Implementation of AMS in Supply Chain Management

Several case studies highlight the successful implementation of AMS in automating supply chain operations:

- Large Retailer: Utilized AMS to reduce customs processing time by 50%, allowing faster market entry and higher service levels.

- Global Logistics Company: Streamlined customs compliance procedures with AMS, reducing error risks and improving delivery times.

Additionally, a recent survey by ShipScience found that 80% of supply chain professionals reported increased efficiency and cost savings post-AMS implementation. The survey also highlighted improved visibility and collaboration across the supply chain, leading to better decision-making and enhanced customer satisfaction.

Future of Supply Chain Automation with Automated Manifest System (AMS)

The future of supply chain automation with AMS looks promising. The adoption of AMS is expected to grow as more shippers recognize its benefits in enhancing supply chain efficiency, reducing costs, and improving customer service.

Advancements in technology will likely make AMS even more effective in:

- Streamlining Operations: Continued improvements will further reduce risks and errors while enhancing service delivery times.

- Real-Time Tracking and Visibility: Enhanced tracking capabilities will allow for better monitoring and quick resolution of issues.

- Regulatory Compliance: AMS will continue to aid in adhering to evolving customs regulations by providing accurate and timely shipment information.

Furthermore, AMS is anticipated to significantly impact sustainability efforts within supply chains. By automating processes, AMS can help reduce the carbon footprint of logistics operations through optimized routing, minimizing empty miles, and decreasing the reliance on paper-based documentation. These improvements not only support companies in meeting sustainability goals but also enhance their reputation among environmentally conscious consumers.

A Logistics Management article projects that AMS integration with emerging technologies like artificial intelligence and blockchain will further transform supply chain operations, making them more resilient and adaptive to future challenges.

Maximizing ROI with AMS: A Comprehensive Guide

Maximizing Return on Investment (ROI) with AMS involves careful planning, implementation, and continuous monitoring of supply chain operations. To achieve optimal ROI, consider the following strategies:

- Identify Automation Opportunities: Pinpoint areas where AMS can enhance operational efficiency and reduce costs, such as customs clearance and compliance procedures.

- Create an Integration Roadmap: Develop a plan for integrating AMS with other supply chain systems to achieve greater visibility and streamline processes.

- Leverage Data Analytics: Utilize data from AMS and other systems to gain insights into operations, identify bottlenecks, forecast demand, and optimize inventory levels.

- Invest in Training: Ensure that your team is well-trained in using AMS to maximize its benefits and maintain operational efficiency.

Implementing these strategies can lead to a 30% increase in supply chain efficiency and a 20% reduction in operational costs, as reported by the ShipScience ROI Report.

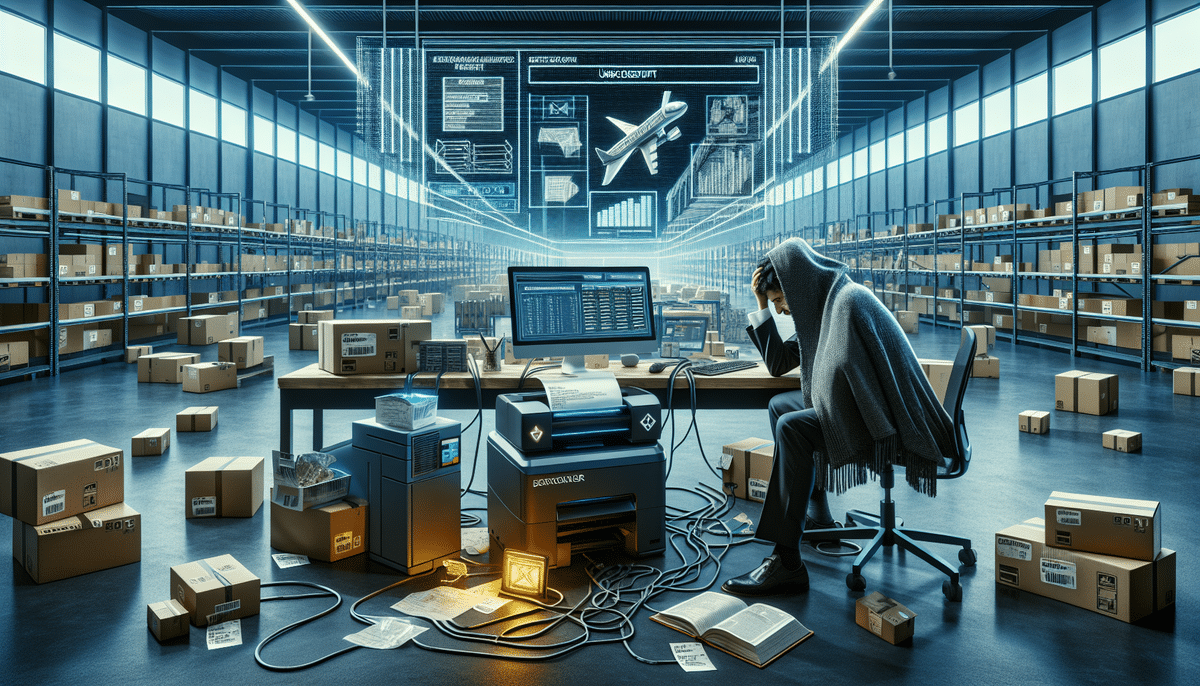

Overcoming Challenges in Implementing Automated Manifest System (AMS) in Your Supply Chain Management

Implementing AMS in supply chain management may present several challenges, including:

- Resistance to Change: Employees may be hesitant to adopt new technologies.

- Limited Resources: Budget constraints and limited personnel can hinder implementation.

- Lack of Knowledge: Understanding the AMS implementation process may be difficult without expertise.

- Complex Supply Chain Operations: Complex logistics can complicate AMS integration.

To overcome these challenges:

- Communicate the Benefits: Clearly articulate the advantages of AMS to gain buy-in from all stakeholders.

- Provide Training and Resources: Equip your team with the necessary skills and knowledge to effectively use AMS.

- Partner with Experts: Collaborate with experienced AMS providers or consultants to ensure a smooth implementation.

By addressing these challenges proactively, businesses can successfully implement AMS and reap the benefits of supply chain automation, including increased efficiency, reduced costs, and enhanced customer service.

Conclusion

In summary, automating the supply chain with the Automated Manifest System (AMS) is increasingly becoming a cornerstone of effective supply chain management. AMS enables shippers to streamline customs clearance processing, reduce the risk of errors and delays, and improve service delivery times. When integrated with other supply chain systems, AMS can achieve even greater efficiency, leading to cost reductions and enhanced customer satisfaction.

While challenges exist in implementing AMS, careful planning, effective strategies, and collaboration with experienced partners can overcome these obstacles and maximize ROI. The future of supply chain automation with AMS is optimistic, with ongoing technological advancements set to make supply chain operations more efficient, resilient, and sustainable.

For more information on implementing AMS and optimizing your supply chain, visit our resources page.