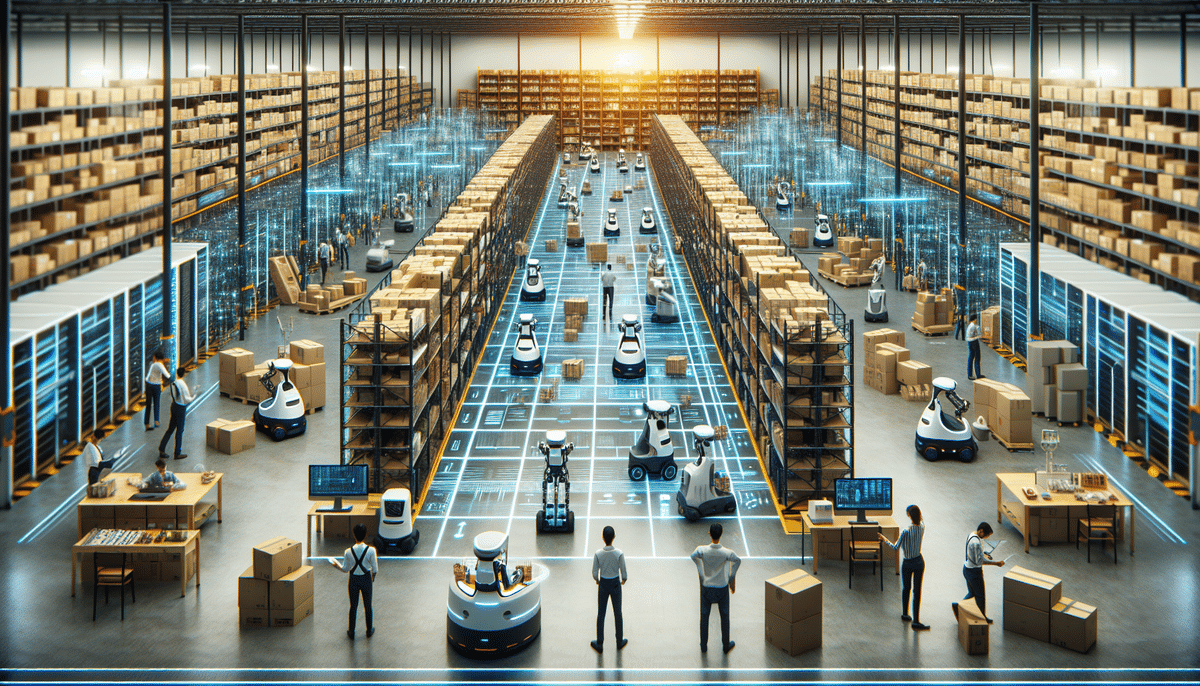

Introduction to Warehouse Automation

In today's fast-paced logistics landscape, warehouse automation has become a critical component for businesses aiming to enhance efficiency and meet increasing consumer demands. Among the myriad of automation solutions available, AutoStore and Kiva Systems (now known as Amazon Robotics) stand out as two of the most prominent systems. This article delves into the mechanisms, features, cost-effectiveness, and impacts of both systems, providing a comprehensive guide to help businesses make informed decisions.

Overview of AutoStore and Kiva Systems

What is AutoStore?

AutoStore is a cube-based automated storage and retrieval system that utilizes small robots to transport product bins within a densely packed grid structure. Renowned for its high storage density and flexibility, AutoStore allows warehouses to maximize space efficiency, storing up to four times more inventory than traditional shelving systems (AutoStore Official Website). The system is easily reconfigurable, enabling businesses to adapt swiftly to changing inventory needs without significant downtime.

What is Kiva Systems?

Kiva Systems, rebranded as Amazon Robotics, employs a fleet of mobile robots to transport entire shelves of products directly to human workers at picking stations. This approach significantly increases speed and scalability, allowing for rapid order fulfillment and seamless expansion to accommodate growing business demands (Amazon Robotics). Kiva Systems are highly adaptable, capable of handling various product types and volumes with minimal reconfiguration.

Working Mechanisms of AutoStore and Kiva Systems

How AutoStore Operates

AutoStore's system consists of a hexagonal grid of cubes stacked to form a compact storage structure. Robots traverse the top of this grid, moving along predefined paths to fetch or store bins. Each robot is equipped with a lifting mechanism to access bins from the top of the stack and transport them to designated workstations where human operators pick items for orders. The sophisticated software coordinating the robots ensures optimized movement patterns, minimizing travel time and maximizing efficiency.

How Kiva Systems Operate

Kiva Systems utilize mobile robots that navigate the warehouse floor to retrieve entire shelves, known as pods, and transport them to fixed picking stations. Workers at these stations then manually pick items from the pods to fulfill orders. The central control system directs the robots, ensuring seamless coordination and reducing idle time. The absence of fixed rails or tracks allows for greater flexibility in warehouse layouts and easier scalability as business needs evolve.

Comparative Analysis: AutoStore vs. Kiva Systems

Storage Density and Space Utilization

AutoStore offers superior storage density, allowing warehouses to store more items within a smaller footprint. Its grid-based design maximizes vertical space, making it ideal for facilities with limited floor area. In contrast, Kiva Systems require more horizontal space due to the need for robot navigation pathways and pod storage, potentially resulting in a larger overall warehouse footprint.

Flexibility and Scalability

Kiva Systems excel in flexibility, easily accommodating various product sizes and types without significant reconfiguration. Their modular design allows businesses to scale operations up or down rapidly in response to demand fluctuations. AutoStore, while flexible in storage configuration, may require more intricate adjustments when scaling, especially in environments with dynamic inventory profiles.

Cost-Effectiveness

From a cost perspective, Kiva Systems typically involve lower initial capital investments and are less maintenance-intensive. Their energy-efficient robots and simpler infrastructure contribute to long-term savings. AutoStore, although involving higher upfront costs due to its complex grid system, can lead to significant savings through space optimization and reduced labor requirements over time.

Integration with Existing Systems

Both AutoStore and Kiva Systems offer robust integration capabilities with existing Warehouse Management Systems (WMS). Kiva Systems are often praised for their seamless integration process, allowing businesses to incorporate robotic automation without overhauling their current operations. AutoStore's advanced software analytics also facilitate smooth integration, providing real-time data on inventory levels and operational performance.

Cost and Efficiency Considerations

Initial Investment and ROI

Kiva Systems generally require a lower initial investment compared to AutoStore, making them accessible to a broader range of businesses. The return on investment (ROI) for Kiva Systems can be realized quickly through labor cost reductions and increased order processing speeds. AutoStore's higher initial costs are offset by its ability to maximize storage capacity and operational efficiency, leading to substantial ROI over the long term.

Operational Efficiency

AutoStore's high storage density reduces the physical space required for storage, allowing for more efficient use of existing warehouse facilities. This efficiency translates to lower operational costs and streamlined inventory management. Kiva Systems enhance operational efficiency by minimizing the time between order receipt and fulfillment, thereby increasing throughput and customer satisfaction.

Maintenance and Energy Consumption

Kiva Systems are known for their low maintenance requirements and energy-efficient operation, contributing to ongoing cost savings. AutoStore's complex grid and robot coordination system may necessitate more frequent maintenance, but its energy consumption remains competitive due to the optimized movement patterns and reduced need for auxiliary systems.

Impact on Warehouse Automation and Future Trends

Enhanced Productivity and Accuracy

The implementation of AutoStore and Kiva Systems has led to significant improvements in warehouse productivity and order accuracy. Automation reduces human error, ensures consistent handling of products, and accelerates the order fulfillment process, which is crucial in meeting the demands of e-commerce and just-in-time delivery models.

Technological Advancements

Future trends in warehouse automation are poised to further integrate technologies such as Artificial Intelligence (AI), Internet of Things (IoT), and Big Data analytics. These advancements will enhance the capabilities of systems like AutoStore and Kiva Systems, enabling predictive maintenance, real-time inventory tracking, and more sophisticated decision-making processes.

Sustainability and Energy Efficiency

As businesses increasingly prioritize sustainability, automated systems are being designed to optimize energy usage and reduce waste. Both AutoStore and Kiva Systems contribute to greener warehouse operations by minimizing energy consumption through efficient robot movements and reducing the need for extensive storage infrastructure.

Case Studies of Companies Using AutoStore and Kiva Systems

Success Stories with AutoStore

Companies like Zalando and Boehringer Ingelheim have successfully integrated AutoStore into their warehouse operations. Zalando, a leading online fashion retailer, leveraged AutoStore to enhance their order fulfillment speed and storage efficiency, enabling them to process a higher volume of orders with greater accuracy.

Success Stories with Kiva Systems

Retail giants such as The Gap and Staples have adopted Kiva Systems to streamline their warehousing processes. These companies have reported significant improvements in order processing times and overall operational efficiency, allowing them to better meet customer expectations and manage large inventories effectively.

Choosing the Right System for Your Business

Assessing Your Warehouse Needs

When deciding between AutoStore and Kiva Systems, it's essential to evaluate your specific warehouse requirements. Consider factors such as the types and quantities of products you handle, the available warehouse space, order volume, and the level of flexibility needed to adapt to changing demands.

Evaluating Cost vs. Benefits

Analyze the total cost of ownership, including initial investment, maintenance, and operational costs, against the potential benefits in terms of increased efficiency, space utilization, and labor savings. This evaluation will help determine which system offers the best ROI for your business.

Consulting with Automation Experts

Engaging with warehouse automation consultants can provide valuable insights and recommendations tailored to your business needs. These experts can assist in assessing your current operations, identifying bottlenecks, and determining the most suitable automation solution to enhance your warehouse performance.

Pros and Cons of Each System

AutoStore

- Pros:

- High storage density

- Flexible and reconfigurable layout

- Advanced software analytics

- Optimized space utilization

- Cons:

- Higher initial capital investment

- More complex maintenance requirements

- Potentially larger footprint for robot movement

Kiva Systems

- Pros:

- Lower initial investment

- High flexibility and scalability

- Energy-efficient operations

- Easy integration with existing systems

- Cons:

- Lower storage density compared to AutoStore

- Requires more floor space for robot navigation

- Potentially higher ongoing maintenance costs

Conclusion: Which System is the Best Fit for Your Business?

Both AutoStore and Kiva Systems offer robust solutions for warehouse automation, each with its unique strengths and considerations. AutoStore is ideal for businesses seeking maximum storage efficiency and advanced inventory management, while Kiva Systems are well-suited for operations requiring high flexibility and rapid scalability. By thoroughly assessing your warehouse needs, evaluating cost implications, and consulting with automation experts, you can select the system that best aligns with your operational goals and positions your business for future growth.