Understanding Package Girth

The girth of a package refers to the measurement around the package perpendicular to its length. Specifically, it is calculated by adding the width and height of the package and multiplying the sum by two. Accurate measurement of girth is crucial for determining shipping costs, ensuring safe transportation, and complying with carrier specifications.

Importance of Girth in Shipping

Package girth plays a significant role in several aspects of the shipping process:

- Shipping Costs: Most shipping carriers use girth, along with package weight, to calculate shipping fees. Larger girth can lead to higher costs.

- Transportation Efficiency: Packages with excessive girth may not fit properly on conveyor belts or in delivery vehicles, leading to delays and potential damage.

- Regulatory Compliance: Carriers have specific girth limits to ensure packages meet transportation standards. Exceeding these limits can result in additional fees or shipment rejection.

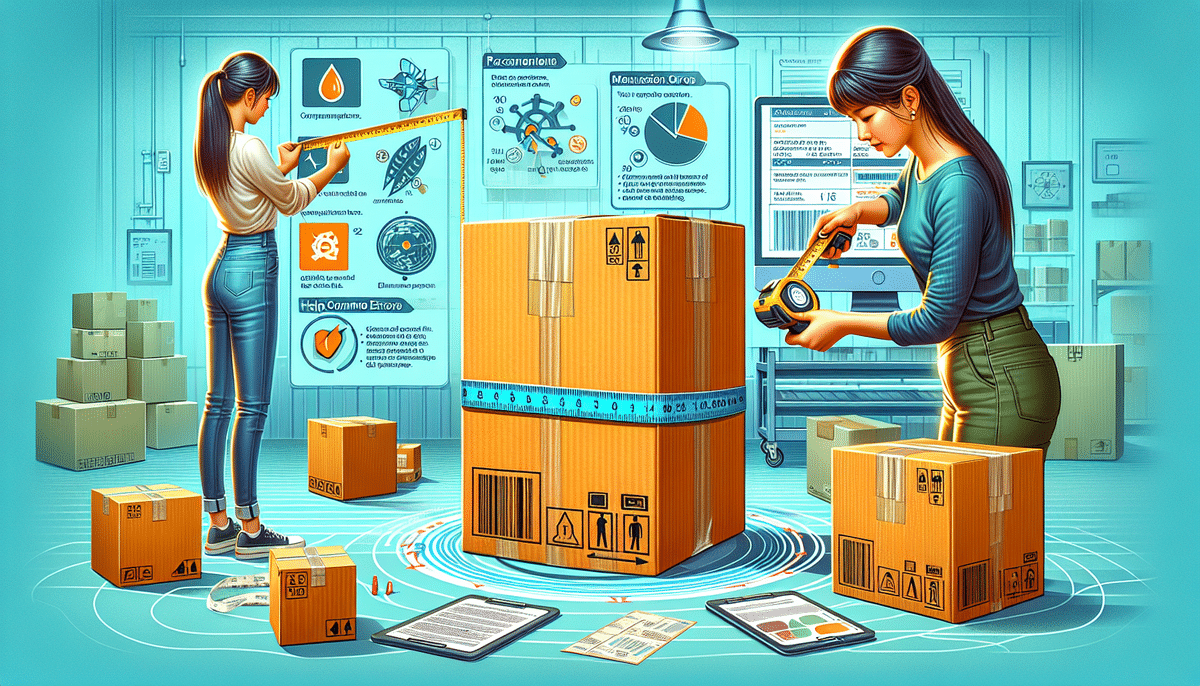

Measuring Package Girth Accurately

Accurate measurement of package girth is essential for avoiding unnecessary shipping costs and ensuring the safe transport of goods. Follow these steps to measure girth correctly:

- Identify the Widest Part: Place the package upright and determine the largest circumference around the package perpendicular to its length.

- Use Appropriate Tools: Utilize a flexible measuring tape or a piece of string to measure the distance around the widest part of the package.

- Account for Protrusions: Include any handles, wheels, or other extensions in your measurement to ensure accuracy.

- Calculate Girth: If the package has irregular dimensions, take multiple measurements and use the formula: Girth = 2 × (Width + Height).

Be aware that different shipping carriers may have specific guidelines for measuring girth. Always consult the carrier's official resources to ensure compliance.

Impact of Girth on Shipping Costs and Security

Shipping costs are directly influenced by both the weight and girth of a package. Here's how girth affects these factors:

- Cost Calculation: Carriers often use a dimensional weight formula, which considers both weight and girth, to determine shipping fees. Larger girth can increase the dimensional weight, leading to higher costs even if the actual weight is low.

- Package Security: Packages with larger girth may be more challenging to secure during transit, increasing the risk of damage. Proper packaging techniques are essential to mitigate this risk.

According to the latest industry reports, optimizing package girth can lead to significant cost savings and improved delivery times.

Optimizing Packaging to Reduce Girth

Reducing package girth not only lowers shipping costs but also enhances transportation efficiency. Here are some strategies to optimize packaging:

- Choose the Right Box Size: Select a box that closely fits the dimensions of your product to minimize excess space.

- Use Lightweight Materials: Opt for materials like lightweight cardboard or biodegradable packing peanuts to reduce overall package size.

- Employ Vacuum-Sealed Packaging: For items like clothing and linens, vacuum-sealed bags can significantly reduce package girth.

- Avoid Overpacking: Ensure that the package is not unnecessarily bulky by removing empty spaces and avoiding multiple layers of packaging.

Girth in International Shipping Regulations

International shipments are subject to varying girth regulations depending on the destination country:

- European Union: Maximum girth limit of 300 cm for international shipments.

- Australia: Restrictions on certain packaging materials to prevent environmental hazards.

- Asia: Specific girth requirements can vary widely between countries, necessitating thorough research before shipping.

Compliance with these regulations is essential to avoid additional fees or shipment rejections. Always verify the girth and packaging requirements with your chosen carrier before sending international packages.

Technological Advances and Future Trends in Girth Calculation

Advancements in technology have revolutionized the way package girth is calculated and managed:

- Automated Software Systems: Many carriers now use software that automatically calculates girth based on input dimensions, reducing human error.

- 3D Scanning Technology: This allows for precise measurements of irregularly shaped packages, ensuring accurate girth calculations.

- Mobile Measurement Apps: Apps utilizing augmented reality enable users to measure package girth using smartphone cameras, streamlining the shipping process.

Looking ahead, these technologies are expected to further enhance accuracy and efficiency in shipping operations, making girth measurement an even more integral part of the e-commerce landscape.

The Future of Girth and Its Impact on E-commerce

As e-commerce continues to expand, the role of package girth in shipping logistics becomes increasingly significant:

- Cost Optimization: Businesses will seek innovative packaging solutions to minimize girth, thereby reducing shipping expenses.

- Customer Experience: Accurate girth measurements ensure timely deliveries and reduce instances of shipping delays or damages, enhancing overall customer satisfaction.

- Environmental Considerations: Minimizing girth leads to reduced packaging material usage, contributing to more sustainable shipping practices.

By prioritizing girth optimization, e-commerce businesses can achieve cost savings, improve operational efficiency, and foster a positive brand image.

Conclusion

Understanding and accurately measuring package girth is essential for effective shipping, cost reduction, and enhancing customer satisfaction. By avoiding common measurement mistakes, optimizing packaging, and leveraging technological advancements, businesses can streamline their shipping processes and achieve significant savings. Stay informed about international regulations and future trends to maintain a competitive edge in the evolving e-commerce landscape.