What is Box Girth and Why It Matters?

The girth of a box refers to the total distance around its thickest part, typically calculated by adding the length and width of the box and multiplying by two. This measurement is a critical factor used by shipping carriers like UPS and FedEx to determine shipping costs, assess package eligibility for specific services, and ensure compliance with size restrictions.

Understanding box girth is essential for businesses to optimize their shipping strategies, control costs, and maintain product integrity during transit.

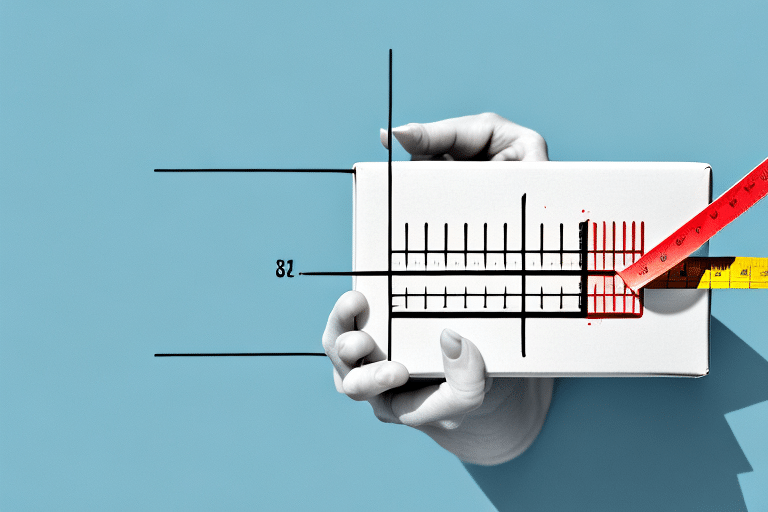

How to Accurately Measure Box Girth

Step-by-Step Measurement Guide

- Measure the Length: Use a flexible measuring tape to determine the longest side of the box.

- Measure the Width: Measure the side perpendicular to the length.

- Calculate the Girth: Add the length and width, then multiply by two. For example, a box with a length of 12 inches and a width of 8 inches has a girth of 40 inches.

Common Mistakes and How to Avoid Them

- Measuring the Wrong Part: Always measure the thickest part of the box to ensure accuracy.

- Ignoring Protrusions: Include any handles or flaps in your measurements as they can affect the total girth.

- Inconsistent Units: Use consistent units of measurement, preferably inches, as most carriers use this standard.

The Impact of Box Girth on Shipping Costs

Shipping carriers use box girth in combination with weight and destination to calculate shipping costs. Larger girth measurements often result in higher shipping fees due to increased space requirements and handling complexities.

For instance, UPS defines oversized packages as those exceeding a certain girth and length threshold, which incurs additional fees. Understanding these parameters can help businesses select the most cost-effective shipping options.

According to the UPS Shipping Guide, managing box girth effectively can lead to significant savings, especially for businesses that ship products frequently.

Strategies to Optimize Box Girth for Efficiency and Cost

Choosing the Right Box Size and Shape

Selecting a box that closely fits the product minimizes excess girth, reducing shipping costs and the need for additional packing materials. Custom-sized boxes can be a worthwhile investment for businesses aiming to optimize their packaging efficiency.

Utilizing Efficient Packaging Materials

Using materials like bubble wrap or foam inserts can protect products without significantly increasing girth. Additionally, innovative packaging solutions such as flexible packaging can adapt to product shapes, further reducing unnecessary space.

Case Studies

Companies like Amazon leverage automated systems to select optimal box sizes based on product dimensions, effectively managing girth and reducing shipping costs. Similarly, Dollar Shave Club uses flexible packaging materials to conform to product shapes, minimizing girth and enhancing customer satisfaction.

Future Trends in Packaging and Box Girth

Sustainable Packaging Materials

The shift towards environmentally friendly packaging is influencing box girth. Sustainable materials like biodegradable plastics and recycled cardboard offer flexibility and durability, allowing for reduced girth without compromising product safety.

Automation and IoT in Packaging

Advancements in automation and the Internet of Things (IoT) are revolutionizing packaging processes. Smart packaging systems can dynamically adjust box sizes in real-time, optimizing girth and improving overall shipping efficiency.

Research by Pack World highlights how these technologies are set to significantly reduce packaging waste and enhance logistic operations in the coming years.

Conclusion: Mastering Box Girth for Business Success

Accurately measuring and optimizing box girth is a fundamental aspect of effective shipping and packaging strategies. By understanding how girth impacts shipping costs, implementing efficient packaging techniques, and staying abreast of emerging trends, businesses can achieve significant cost savings, enhance product protection, and improve overall operational efficiency.

Investing time and resources into mastering box girth not only streamlines the shipping process but also contributes to better customer experiences and stronger brand reputation in a competitive marketplace.