Understanding CBM: Definition and Basics

CBM stands for cubic meters, a fundamental measurement unit in the shipping industry. It calculates the volume of cargo being transported, determining how much space your goods will occupy in a container or vessel. Understanding CBM is essential for freight forwarders to select the appropriate container size, ultimately influencing shipping costs.

What is CBM?

CBM is derived by multiplying the length, width, and height of the cargo, resulting in the total volume in cubic meters. For example, a cargo measuring 2 meters in length, 1.5 meters in width, and 1.5 meters in height will have a CBM of 4.5 cubic meters.

Why CBM Matters

CBM accuracy is paramount, especially for bulky or irregularly shaped cargo, as it provides a realistic estimation of space requirements, optimizing container usage and minimizing unnecessary costs. Accurate CBM calculations can lead to up to a 10% reduction in shipping costs and improve overall logistics efficiency (International Maritime Organization).

Calculating CBM: Methods and Tools

Accurate CBM calculation involves precise measurement of the cargo, including packaging and pallets. The basic formula is:

CBM = Length (m) × Width (m) × Height (m)

For example:

- Length: 2 meters

- Width: 1.5 meters

- Height: 1.5 meters

- CBM = 2 × 1.5 × 1.5 = 4.5 cubic meters

Tools for CBM Calculation

- Manual Calculations: Utilizing measuring tapes and calculators.

- Software Solutions: Advanced freight forwarding software that automates CBM calculations, enhancing accuracy and efficiency.

- 3D Scanning Technology: Emerging technologies like 3D scanning provide precise measurements for irregularly shaped cargo.

Best Practices for Measurement

- Always use external dimensions, accounting for packaging.

- Consider any protrusions or irregularities in the cargo.

- Double-check measurements to avoid discrepancies.

The Importance of CBM in International Shipping

In international shipping, CBM is integral for:

- Container Selection: Choosing the right container size based on cargo volume.

- Cost Estimation: Calculating shipping costs, which often depend on CBM.

- Space Optimization: Ensuring efficient use of container space, reducing fuel consumption and emissions.

- Compliance: Adhering to shipping regulations regarding container loading weights and dimensions.

Impact on Shipping Rates

Freight charges are typically calculated based on either CBM or weight, whichever is greater. According to IATA, accurate CBM assessments help avoid unexpected costs and ensure competitive pricing, with up to 15% cost savings achievable through optimized volume handling.

Environmental Considerations

Efficient CBM usage contributes to environmental sustainability by minimizing fuel consumption and emissions through optimized space utilization, aligning with global efforts to reduce the shipping industry's carbon footprint.

CBM vs Weight: Impact on Freight Charges

Shipping costs are influenced by both CBM and weight, with pricing structures often based on the higher value between the two. This is known as dimensional weight pricing.

When CBM Takes Priority

For lightweight but bulky items, CBM is the dominant factor in determining shipping costs. Examples include electronics, furniture, and textiles, where volume impacts container space more significantly than mass.

When Weight Matters More

For dense and heavy goods like machinery, metals, and construction materials, weight is the primary factor in freight charges. Overloading containers can lead to safety hazards and increased handling costs.

Calculating Dimensional Weight

Dimensional weight is calculated by dividing the CBM by a factor determined by the shipping carrier (commonly 6 for air freight). The higher of the actual weight or dimensional weight is used for billing, ensuring fair pricing based on space or mass requirements.

Common Misconceptions About CBM

CBM Equals Weight

One prevalent myth is that CBM is synonymous with weight. In reality, CBM measures volume, while weight measures mass. Both dimensions separately influence shipping logistics and costs.

CBM is Only for Large Shipments

Another misconception is that CBM is relevant only for large cargos. However, CBM is beneficial for optimizing space and costs even for smaller shipments, enhancing efficiency across various shipment sizes.

Overlooking Packaging Impact on CBM

Improper packaging can inflate CBM, leading to higher shipping costs. Utilizing space-efficient packaging methods can significantly reduce CBM, as demonstrated by industry reports showing up to 20% cost reductions through optimized packaging strategies (Forbes).

Maximizing CBM Efficiency: Best Practices

Optimizing CBM usage ensures cost-effective and efficient shipping processes. Implementing the following strategies can lead to significant improvements:

Efficient Packaging

- Use nestable or foldable packaging to save space.

- Choose appropriate packaging materials that minimize volume.

- Implement standardized packaging sizes for easier stacking and arrangement.

Optimal Loading Plans

- Employ advanced loading software to maximize container space.

- Create systematic loading sequences to prevent unused spaces.

- Utilize techniques like vertical stacking and multi-layer packing.

Balanced Weight Distribution

- Distribute cargo evenly to maintain container stability.

- Secure items properly to prevent shifting during transit.

- Follow container weight limits to avoid overloading and related penalties.

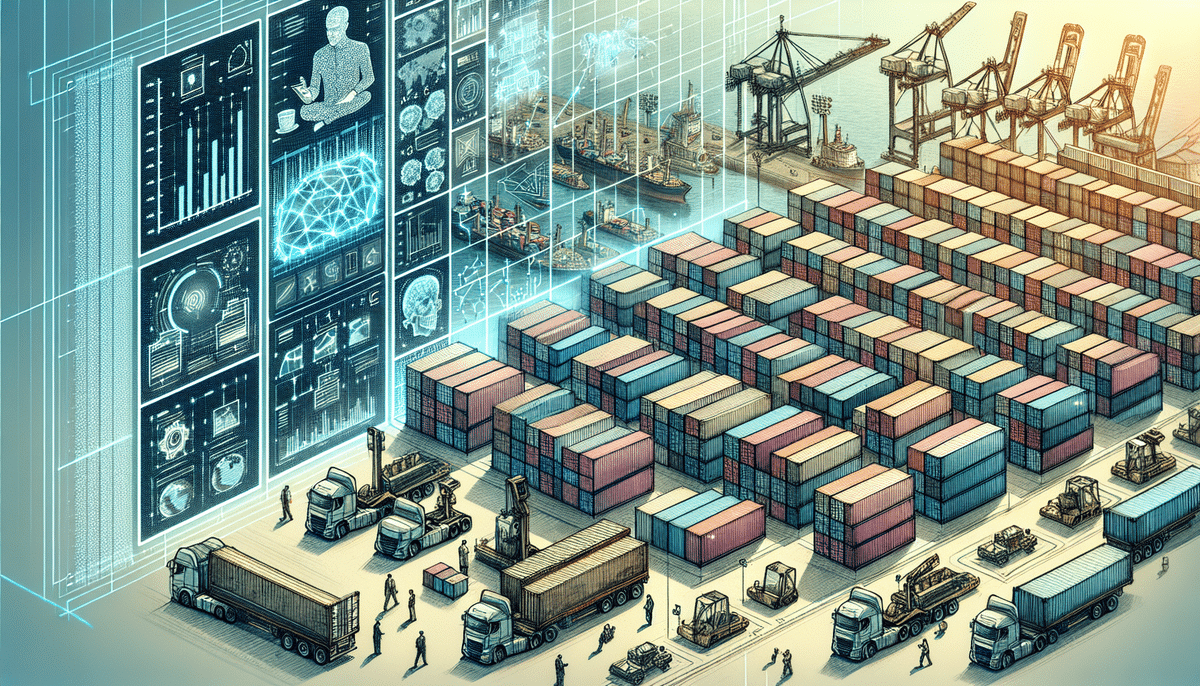

Utilizing Technology

Integrate CBM calculation tools and container optimization software to enhance accuracy and efficiency, leveraging technologies such as AI and machine learning for predictive logistics planning.

Regular Audits and Continuous Improvement

Conduct audits on CBM measurements and loading processes to identify areas for improvement, ensuring that practices evolve with industry standards and technological advancements.

The Future of CBM: Technological Advancements and Trends

Technological innovations are transforming CBM calculation and management, driving greater efficiency and accuracy in the shipping industry:

Automation and AI

Artificial Intelligence enables automated CBM calculations, predictive analytics for space optimization, and real-time tracking, reducing human error and increasing operational efficiency (IBM AI).

Blockchain Integration

Blockchain technology enhances transparency and security in shipping transactions, including CBM data integrity, facilitating trust and accuracy in global supply chains.

IoT and Smart Packaging

Internet of Things (IoT) devices facilitate precise monitoring and reporting of cargo dimensions and conditions, enabling dynamic CBM adjustments and real-time management.

Sustainable Practices

Advancements in CBM contribute to sustainability by enabling more efficient use of space, reducing fuel consumption, and lowering carbon emissions, aligning with global environmental goals.

Digital Platforms and Integration

Cloud-based shipping platforms offer integrated CBM tools, improving accessibility and collaboration across supply chains, and supporting seamless data exchange between stakeholders.