Conducting a Comprehensive Shipping Audit for Optimal Efficiency

As a business owner or manager, optimizing your shipping processes is crucial to ensure timely delivery, customer satisfaction, and cost savings. Conducting a comprehensive shipping audit is one way to achieve these goals. This article discusses the importance of shipping audits, key components of a successful audit process, and best practices for identifying shipping costs and reducing overhead expenses.

Understanding the Importance of Shipping Audits for Your Business

Shipping audits can help identify inefficiencies, reduce costs, and ultimately improve your bottom line. By conducting a thorough analysis of your shipping data, you can identify areas for improvement and implement changes to streamline your operations. Shipping audits also provide an opportunity to measure the effectiveness of any changes made and adjust as needed.

One key benefit of shipping audits is identifying compliance issues that may be affecting your business. This is particularly important if you are shipping goods internationally, as there are a number of regulations and requirements that must be met. By conducting regular audits, you can ensure that your business is in compliance with all relevant laws and regulations, avoiding potential penalties or fines. For more information on international shipping regulations, visit the U.S. Customs and Border Protection.

In addition to identifying inefficiencies and compliance issues, shipping audits can improve customer satisfaction. By analyzing your shipping data, you can identify areas where customers may experience delays or other issues and address these problems. This can help build stronger relationships with your customers and improve your reputation and bottom line.

Key Components of a Successful Shipping Audit Process

Evaluating Current Shipping Processes

Evaluate your current shipping processes by analyzing data on delivery times, shipping costs, and customer satisfaction rates. Pinpoint inefficiencies to focus improvement efforts.

Establishing Communication with Shipping Carriers

Establish clear communication channels with your shipping carriers. Set expectations for delivery times, tracking packages, and resolving issues that may arise during the shipping process. Consider using multiple carriers to optimize costs and performance. For insights on selecting the right shipping carriers, refer to this PwC report.

Reviewing and Updating Shipping Policies

Regularly review and update your shipping policies and procedures to align with industry standards and best practices. This ensures that your shipping operations remain efficient and cost-effective.

Analyzing and Improving Shipping Data

Conducting Thorough Shipping Data Analysis

Collect and review data on shipping volumes, delivery times, shipping costs, and customer satisfaction levels. Use analytical tools to identify trends, patterns, and areas for improvement. Tools such as data visualization and statistical analysis can help uncover insights.

Implementing Best Practices to Reduce Shipping Costs

Negotiate favorable rates with carriers and consider using multiple carriers to minimize costs. Implement shipping software that automates shipping processes, reduces manual errors, and enhances efficiency. Learn more about the benefits of shipping software on Business News Daily.

Optimizing Packaging Materials

Choose the right packaging materials and sizes to reduce shipping costs and minimize damages during transit. Sustainable packaging practices can also reduce waste and lower costs in the long run.

Leveraging Technology to Streamline Shipping Operations

Implementing Shipping Software

Shipping software can automate processes such as label printing, tracking, and order management, reducing time and resources required for shipping and minimizing potential human error. Explore the advantages of shipping software in this Forbes article.

Using Transportation Management Systems (TMS)

A Transportation Management System (TMS) can optimize shipping routes and reduce transportation costs while providing real-time visibility into your shipments. Learn more about TMS benefits and challenges on Supply Chain Digital.

Implementing Warehouse Management Systems (WMS)

A Warehouse Management System (WMS) optimizes warehouse operations by automating inventory management, order fulfillment, and picking and packing processes, reducing errors and improving efficiency.

Implementing and Measuring Audit Results

Creating an Action Plan

Create an action plan based on audit results, including specific goals, timelines, and responsibilities. Communicate the plan with relevant stakeholders to ensure buy-in and support.

Monitoring Progress and Adjusting as Needed

Regularly monitor and evaluate the progress of the action plan to identify roadblocks or challenges. Adjust the plan as necessary and celebrate successes to maintain momentum.

Measuring Effectiveness

Measure the effectiveness of your shipping audit by monitoring key performance indicators such as delivery times, shipping costs, and customer satisfaction levels. Conduct customer surveys and analyze shipping error data to identify patterns and make necessary adjustments.

Benefits of Regularly Conducting Shipping Audits

Regular shipping audits help identify and reduce inefficiencies, leading to cost savings and improved customer satisfaction. By adopting best practices and technology, you can stay competitive in a rapidly evolving shipping landscape. Additionally, regular audits enable proactive identification and resolution of potential issues.

Shipping audits also enhance sustainability efforts by identifying opportunities to reduce your carbon footprint, such as optimizing routes or using eco-friendly packaging materials. This benefits the environment and improves your brand image among environmentally conscious customers. For more on sustainable shipping practices, visit the EPA's Sustainable Materials Management.

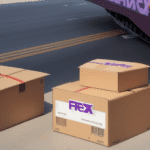

Case Studies: Examples of Companies Who Have Improved Their Shipping Processes Through Audits

- Company A: Conducted a shipping audit and discovered they were overpaying for shipping due to exclusive use of a single carrier. By diversifying carrier options and negotiating better rates, they achieved a 20% cost saving.

- Company B: Implemented shipping software to automate labeling and tracking processes, reducing the time and resources required for shipping and minimizing manual errors.

- Company C: Regularly conducts shipping audits and adjusts processes accordingly, maintaining competitiveness, improving delivery times, reducing costs, and increasing customer satisfaction.

Shipping audits should be an ongoing process, regularly reviewing shipping processes to ensure efficiency and cost-effectiveness. This includes analyzing carrier rates, evaluating packaging options, and assessing delivery times.

Additionally, shipping audits can help companies identify areas for improvement in their sustainability efforts. By analyzing their shipping practices, companies can find ways to reduce their carbon footprint, such as using more eco-friendly packaging materials or optimizing delivery routes to reduce fuel consumption.

Partnering with Third-Party Logistics Providers to Enhance Your Shipping Operations

Partnering with third-party logistics (3PL) providers can enhance your shipping operations by bringing expertise, resources, and networks that your organization may lack in-house. A reliable 3PL can help improve efficiency, reduce costs, and optimize your overall shipping operations. Learn more about the benefits of 3PL partnerships on Supply Chain Digital.

Final Thoughts: Key Takeaways for Conducting a Comprehensive Shipping Audit

Conducting a comprehensive shipping audit is essential for optimizing your shipping operations. Key takeaways include evaluating current shipping processes, thoroughly analyzing shipping data, leveraging technology, creating and implementing an action plan, and regularly measuring the effectiveness of your audit. By following these best practices, you can achieve optimal efficiency, cost-effectiveness, and customer satisfaction in your shipping operations.