Overview of Robotics in Warehousing

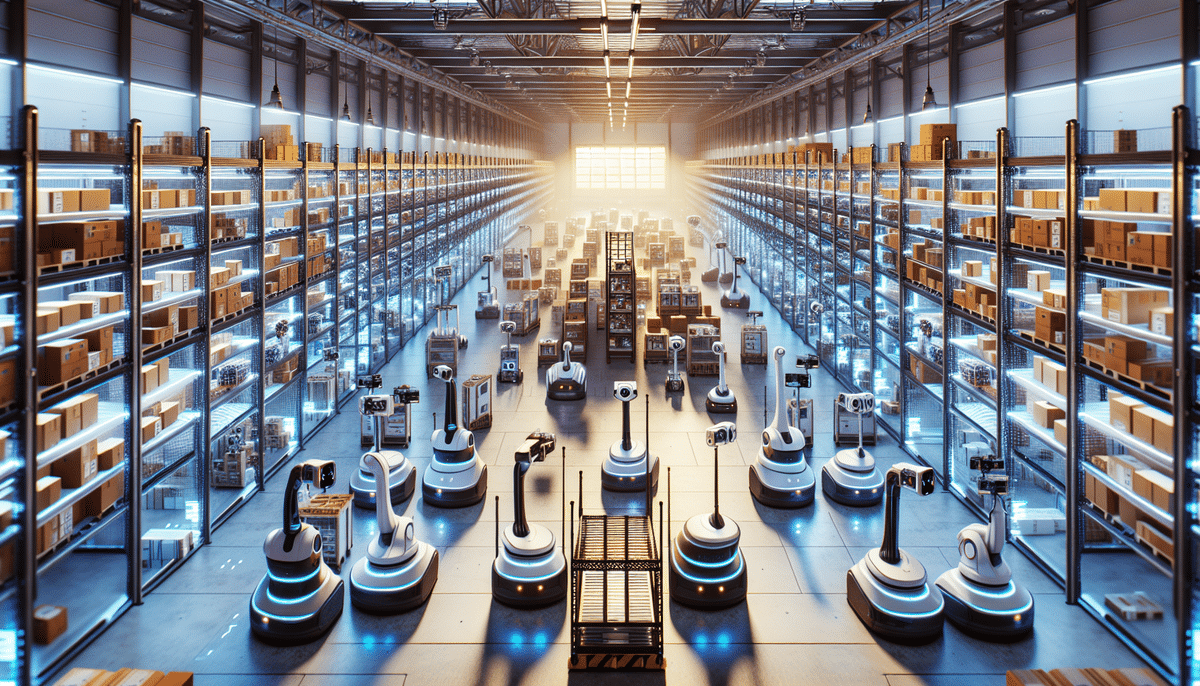

As the logistics and warehousing industry continues to grow, technology plays a pivotal role in meeting the demands of a fast-paced environment. Robotics has emerged as a key innovation, enhancing efficiency and reducing operational costs. Two prominent players in this space are Geek+ and Amazon Robotics (formerly Kiva Systems). This article explores these systems, comparing their advantages and limitations, and examines the broader impact of robotics on the industry.

Comparing Geek+ and Amazon Robotics

Geek+

Geek+ is a Chinese robotics company founded in 2015, specializing in AI-powered robots and software solutions for various industries, including logistics and warehousing. Their autonomous robots handle tasks such as picking and transporting goods, significantly reducing the need for manual labor and boosting operational efficiency. According to their 2023 annual report, Geek+ has deployed over 10,000 robots across 15 countries, partnering with industry giants like Alibaba and Walmart.

Geek+ has received accolades for its innovative technology, including the 2020 RBR50 Robotics Innovation Award. Their global presence extends to the United States, Germany, Japan, and Singapore, facilitating tailored solutions for diverse market needs.

Amazon Robotics

Amazon Robotics, originally founded as Kiva Systems in 2003 and acquired by Amazon in 2012, focuses primarily on automating e-commerce fulfillment processes. Their robotic fulfillment system streamlines the picking, packing, and shipping of orders by utilizing a three-dimensional grid system to organize and transport inventory efficiently. As reported in Amazon's 2023 sustainability report, Amazon Robotics operates over 300,000 robots in Amazon's fulfillment centers worldwide, enhancing speed and accuracy in order processing.

Amazon Robotics continues to innovate with the introduction of the Mobile Fulfillment System, offering greater flexibility in warehouse layout and operations. Their contributions have earned recognition, including being named among the World's Most Innovative Companies by Fast Company in 2013.

A Comprehensive Look at Amazon's Innovations in Logistics Robotics

Robotic Fulfillment Centers

Amazon has heavily invested in its fulfillment centers, integrating advanced robotic technologies to automate operations. The deployment of Amazon Robotics has expedited order processing, reduced errors, and increased overall customer satisfaction.

Drone Delivery Initiatives

Beyond warehouse automation, Amazon is exploring aerial logistics with its Prime Air service, aiming to deliver packages to customers within 30 minutes using unmanned aerial vehicles. In 2023, Amazon successfully completed regulatory approvals for pilot programs in select regions, highlighting the potential of drone delivery to revolutionize the delivery industry.

Sustainable Robotics Practices

Amazon is committed to sustainability, setting a target to achieve net-zero carbon emissions by 2040. The company invests in renewable energy sources, such as wind and solar, to power its fulfillment centers. Additionally, optimizing delivery routes with AI reduces mileage and carbon footprint, aligning robotics deployment with environmental goals.

Benefits of Implementing Robotics in Warehousing

Increased Efficiency and Productivity

Robotics eliminates manual labor constraints by operating 24/7 with high speed and accuracy. For instance, Geek+ robots can handle up to 2,500 parcels per hour, while Amazon Robotics boosts order processing capabilities by up to 80%, as seen in case studies from companies like Zappos.

Enhanced Workplace Safety

Robots take over heavy and repetitive tasks, reducing the risk of workplace injuries and associated insurance costs. This shift also leads to higher employee satisfaction, as workers focus on less physically demanding roles.

Optimized Space Utilization

Robotic systems navigate narrow aisles and high shelves, allowing more efficient use of warehouse space. This optimization can increase storage capacity without the need for costly expansions or relocations.

Improved Inventory Accuracy

Real-time data tracking by robots enhances inventory management, reducing instances of stockouts and overstocking. This accuracy ensures better resource allocation and customer satisfaction.

Challenges and Considerations in Robotics Implementation

Cost of Acquisition and Maintenance

Initial investment for robotics technology can be substantial, particularly for smaller businesses. Additionally, ongoing maintenance and upgrades add to the long-term costs, potentially making it unaffordable for some enterprises.

Integration with Existing Systems

Incorporating robots into current warehouse management systems may require significant changes and adaptations. This integration often involves a learning curve and additional training resources for employees to effectively work alongside robotic systems.

Technological Limitations

Despite advancements, robotics technology may still face limitations in handling certain tasks or adapting to unique operational needs. Ensuring that robotic solutions are fully compatible with specific business requirements is crucial for successful deployment.

Workforce Adaptation

Transitioning to a more automated environment requires employees to adapt to new roles and workflows. Providing adequate training and addressing potential job displacement concerns are essential for maintaining workforce morale and productivity.

The Role of Artificial Intelligence in Enhancing Robotics

Real-Time Decision Making

AI enables robots to perform complex tasks and make informed decisions on the fly. For example, AI-powered robots can analyze data to optimize routing and order selection, enhancing overall efficiency.

Applications Beyond Warehousing

AI-driven robotics extend into various sectors, including healthcare and agriculture. In healthcare, robots assist in patient monitoring and administering medication with precision, while in agriculture, they optimize planting and harvesting processes based on data analysis.

Future Innovations

As AI technology continues to evolve, future robotics will likely feature more advanced capabilities, such as enhanced machine learning for better adaptability and improved human-robot collaboration in diverse operational settings.

Impact of Global Events on Robotics Adoption

COVID-19 Pandemic

The COVID-19 pandemic underscored the importance of automation in maintaining productivity during disruptions. With social distancing measures and workforce limitations, robotics provided a solution to sustain warehouse operations without compromising safety.

Supply Chain Resilience

Global supply chain challenges have accelerated the adoption of robotics, as businesses seek to streamline operations and mitigate risks associated with human-dependent processes.

Case Studies: Success Stories with Geek+ and Amazon Robotics

Geek+ in An Post

An Post, the national postal service provider in Dublin, implemented Geek+ robots and achieved a 60% improvement in efficiency, processing an average of 2,500 parcels per hour.

Amazon and Zappos

Zappos, a leading online shoe retailer owned by Amazon, integrated Amazon Robotics into their fulfillment centers, resulting in an 80% increase in productivity and a significant reduction in order processing time from hours to minutes.

Cost Analysis: Robotics vs. Manual Labor

While the upfront costs of robotics may be higher compared to manual labor, the long-term benefits often outweigh these initial expenses. Robots operate continuously with minimal errors, enhancing productivity and reducing operational costs over time. Additionally, robotics implementation can lead to lower insurance costs and decreased expenses related to workplace injuries, providing a more cost-effective solution in the long run.

The Future of Robotics in Logistics and Warehousing

The trajectory of robotics in logistics and warehousing points towards increased automation and more sophisticated AI integration. Future advancements are expected to bring faster, more efficient robots with enhanced capabilities, making automation even more indispensable across various industries.

As companies continue to embrace robotics, we can anticipate broader adoption of these technologies, leading to more streamlined and resilient supply chains that can adapt to changing market demands and global challenges.

Conclusion

Both Geek+ and Amazon Robotics offer robust solutions to the logistics industry, each with unique strengths and considerations. Businesses must carefully evaluate their specific needs and operational contexts to choose the most suitable system. Despite challenges in cost and integration, the benefits of robotics—ranging from increased efficiency to enhanced safety—underscore their critical role in the future of logistics and warehousing.