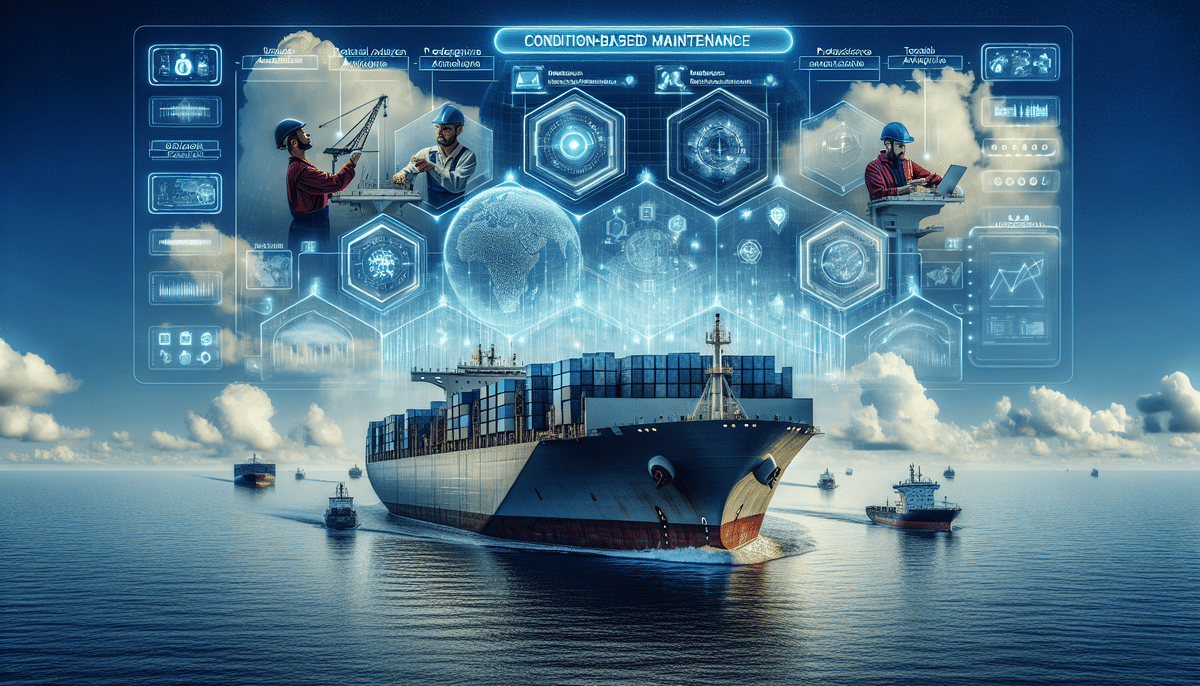

Shipping is a vital component of the global economy, necessitating the efficient and effective management of cargo. One technology that has emerged as a valuable asset in the shipping industry is Condition-Based Maintenance (CBM). By providing real-time data on the condition of critical ship components, CBM technology enables shipping companies to optimize operations and minimize downtime. This article delves into the fundamental concepts of CBM, its economic and operational benefits, challenges in implementation, and its role in enhancing safety, sustainability, and supply chain efficiency within the shipping industry.

Understanding Condition-Based Maintenance (CBM)

What is CBM and How Does it Work in Shipping?

Condition-Based Maintenance (CBM) involves monitoring the actual condition of equipment to decide what maintenance needs to be done. In the shipping industry, CBM utilizes sensors and monitoring tools to collect data from key ship components. By analyzing this data, CBM can identify patterns and predict potential issues before they escalate into critical problems. This proactive approach contrasts with traditional reactive maintenance, which addresses issues only after they occur, often leading to unplanned downtime and higher costs.

The Evolution of CBM in the Shipping Industry

CBM is a relatively recent advancement in the shipping sector. Historically, maintenance schedules were fixed and did not account for the actual condition of equipment, leading to inefficiencies and increased downtime. Advances in sensor technology, data analytics, and the Internet of Things (IoT) have revolutionized CBM, enabling real-time monitoring and more efficient maintenance practices. Today, CBM is integral to modern shipping operations, enhancing performance and reliability across fleets.

Economic and Operational Benefits of CBM

The Economic Benefits of CBM in Shipping

Implementing CBM can lead to significant economic advantages for shipping companies. By reducing unplanned downtime, companies can avoid the high costs associated with emergency repairs and operational interruptions. Additionally, optimized maintenance schedules decrease unnecessary maintenance activities, further lowering operational expenses. According to a McKinsey report, CBM can improve operational efficiency by up to 20%, translating to substantial cost savings and increased profitability.

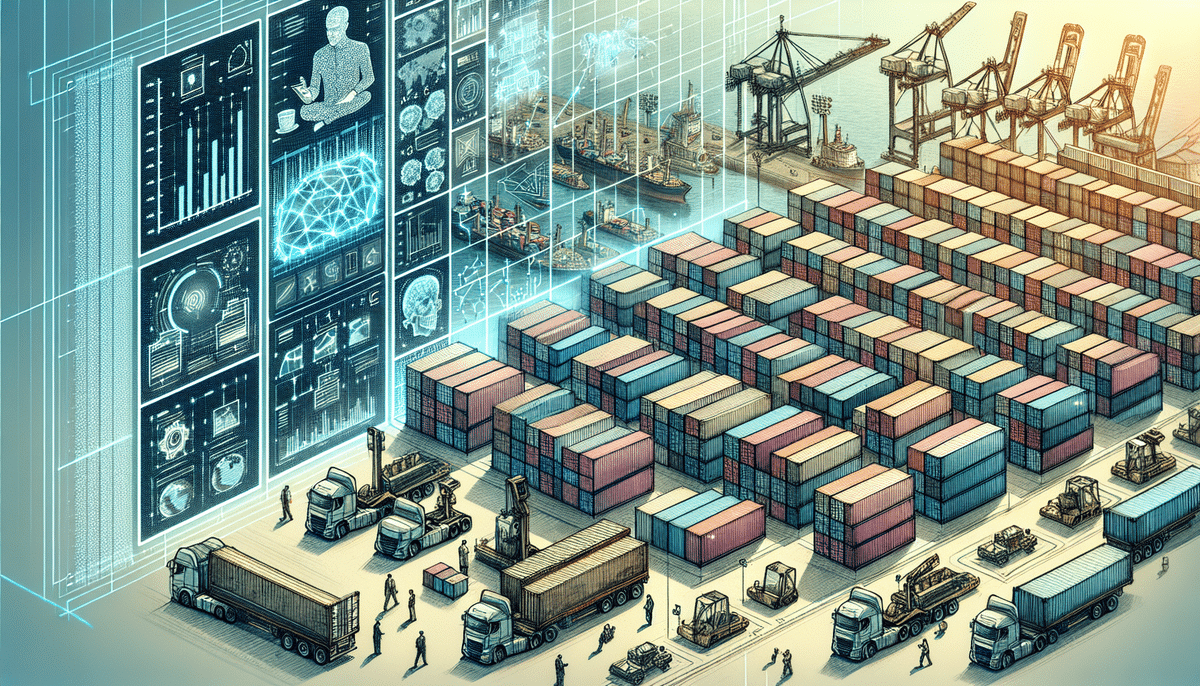

The Role of CBM in Improving Supply Chain Efficiency

Efficient supply chain management is crucial for shipping companies. CBM enhances supply chain efficiency by ensuring that critical components are always functioning optimally. This reduces the likelihood of delays caused by equipment failures and improves the accuracy of delivery times. As a result, customer satisfaction increases, and companies can achieve more reliable service. Additionally, CBM provides valuable data insights that help in optimizing routes and reducing transportation costs.

Understanding the ROI of Investing in CBM Technology

Investing in CBM technology offers a strong return on investment (ROI) for shipping companies. The initial costs of implementing CBM are offset by the long-term savings from reduced downtime, lower maintenance costs, and increased operational efficiency. Furthermore, CBM contributes to enhanced safety and compliance, which can reduce the risk of costly regulatory fines and事故-related expenses. A study by the Bain & Company indicates that companies adopting CBM can see an ROI of 150% within the first two years of implementation.

Enhancing Safety and Sustainability with CBM

How CBM Enhances Safety and Risk Management in the Shipping Industry

CBM plays a critical role in improving safety within the shipping industry by providing early warnings of potential equipment failures. This proactive approach allows for timely maintenance, preventing accidents and enhancing the overall safety of onboard operations. By monitoring essential systems continuously, CBM helps mitigate risks associated with equipment malfunction, thereby fostering a safer working environment for crew members.

How CBM Can Help Reduce Environmental Impact in the Shipping Industry

CBM contributes to environmental sustainability by optimizing the use of resources and reducing waste. Accurate maintenance schedules ensure that equipment operates efficiently, leading to better fuel utilization and lower greenhouse gas emissions. Additionally, minimizing unplanned maintenance reduces the amount of waste generated from parts and materials used in repairs. According to the International Energy Agency, improving maintenance practices can reduce a ship's carbon footprint by up to 10%.

Implementation of CBM in the Shipping Industry

Implementing CBM: Challenges and Solutions for Shipping Companies

While the benefits of CBM are substantial, implementing this technology presents several challenges. Shipping companies must navigate the complexities of integrating CBM systems with existing infrastructure, ensuring compatibility across diverse equipment types. Additionally, there is a need for skilled personnel to manage and interpret the vast amounts of data generated by CBM systems. Solutions include investing in robust training programs, partnering with technology providers for seamless integration, and adopting scalable CBM solutions that can adapt to varying operational needs.

How to Choose the Right CBM Solution for Your Shipping Needs

Selecting the appropriate CBM solution requires careful consideration of a company's specific operational requirements. Key factors include the types of equipment being monitored, the scalability of the CBM system, and the level of technical support offered by the provider. It is essential to choose a CBM solution that offers flexibility, accurate data analytics, and easy integration with existing systems. Additionally, providers should offer comprehensive training and ongoing support to ensure successful implementation and maximum benefits.

Future Trends and Case Studies

The Future of CBM in the Shipping Industry: Trends and Forecast

The future of CBM in the shipping industry is promising, driven by advancements in IoT, artificial intelligence (AI), and machine learning. These technologies enhance the predictive capabilities of CBM, allowing for even more precise maintenance scheduling and operational optimization. Upcoming trends include the integration of CBM with autonomous shipping systems, real-time data sharing across fleets, and the use of augmented reality (AR) for maintenance training and support. These innovations are set to further enhance the efficiency and reliability of shipping operations.

Case Studies: Successful Implementation of CBM in Major Shipping Companies

Several leading shipping companies have successfully integrated CBM into their operations, demonstrating its effectiveness. For instance, Maersk Line has implemented CBM across its fleet, resulting in a 15% reduction in maintenance costs and a 25% decrease in unplanned downtime. Similarly, CMA CGM has utilized CBM to enhance vessel performance and extend equipment lifespan, leading to significant operational savings. These case studies underscore the tangible benefits of CBM in improving both economic and operational outcomes within the shipping industry.

Regulatory and Data Considerations

The Importance of Data Analytics in CBM for Improved Shipping Operations

Data analytics is integral to the success of CBM, enabling shipping companies to extract meaningful insights from the vast amounts of data collected by CBM systems. Advanced analytics tools help in identifying trends, predicting equipment failures, and optimizing maintenance schedules. By leveraging data analytics, companies can make informed decisions that enhance operational efficiency, reduce costs, and improve overall performance.

Regulatory Considerations for Implementing CBM in the Global Shipping Network

Implementing CBM in the shipping industry requires adherence to various regulatory standards and frameworks. Shipping companies must ensure that their CBM systems comply with international maritime regulations, including safety, environmental, and data protection standards. Staying abreast of regional regulations and obtaining necessary certifications is crucial for avoiding legal issues and ensuring seamless operations across different jurisdictions. CBM also aids in maintaining compliance by providing accurate records of equipment conditions and maintenance activities.

Conclusion

The integration of Condition-Based Maintenance (CBM) in the shipping industry is a transformative development that offers extensive benefits in terms of efficiency, cost savings, safety, and sustainability. By providing real-time insights into the health of critical components, CBM enables proactive maintenance, reducing unplanned downtime and enhancing operational reliability. While challenges in implementation exist, the long-term advantages far outweigh these hurdles. As technology continues to advance, CBM is set to play an increasingly pivotal role in shaping the future of shipping, ensuring that companies remain competitive and resilient in a dynamic global market.