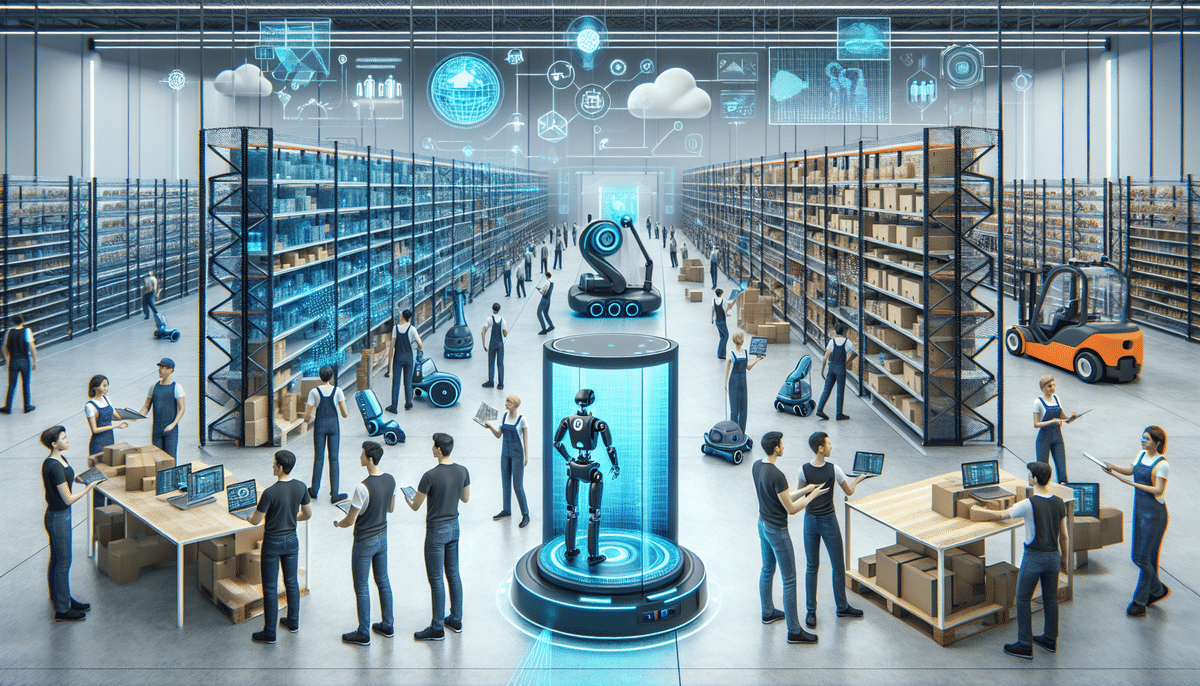

Introduction to Warehouse Robotics

The integration of robotics in warehouses has surged in recent years, fundamentally transforming how goods are stored, managed, and retrieved. According to a McKinsey report, the global warehouse robotics market is expected to grow by over 20% annually through 2025. Among the leading players in this space are Locus Robotics and Fetch Robotics, both of which offer advanced autonomous mobile robots designed to enhance warehouse efficiency and productivity.

Company Profiles: Locus Robotics and Fetch Robotics

Locus Robotics

Founded in 2015 by Bruce Welty and Rick Faulk, Locus Robotics is headquartered in Wilmington, Massachusetts. With over $105 million in funding, the company specializes in developing robots that collaborate seamlessly with human workers. Their LocusBot is designed to support e-commerce, retail, and third-party logistics (3PL) providers by automating order picking and inventory management.

Fetch Robotics

Established in 2014 by Melonee Wise and Steve Hogan, Fetch Robotics operates out of San Jose, California. Garnering more than $94 million in funding, Fetch focuses on creating versatile autonomous mobile robots (AMRs) for a variety of applications, including material handling, data collection, and security within the logistics and manufacturing sectors.

Robot Comparison: LocusBot vs. Fetch Freight

Design and Capabilities

The LocusBot from Locus Robotics is engineered for collaborative work environments. It features omni-directional wheels and advanced sensors that enable precise navigation and safe interaction with human workers. Additionally, the PickMate accessory provides an augmented reality interface to assist workers in identifying and selecting items efficiently.

In contrast, Fetch Robotics offers a range of models such as the Freight and Freight500, both boasting a payload capacity of up to 1,000 lbs. These robots are equipped with sophisticated perception systems that allow for dynamic obstacle avoidance and optimized routing within warehouse settings.

Software and Integration

Locus Robotics utilizes a cloud-based software platform, Locus Robotics Advanced Navigation (LRAN), which provides real-time monitoring, performance optimization, and comprehensive data analytics. This platform empowers warehouse managers with actionable insights to enhance operational efficiency.

Fetch Robotics leverages the Robot Operating System (ROS), an open-source framework that offers greater flexibility for customization. Their Software Development Kit (SDK) allows businesses to tailor the robots' functionalities to specific tasks and workflows, accommodating a broader range of operational needs.

Key Features and Technological Innovations

Locus Robotics Features

- Scalability: Easily scalable to accommodate warehouse growth.

- Gamification: Engages workers through friendly competitions to enhance productivity.

- Advanced Navigation: Utilizes LRAN for efficient pathfinding and task allocation.

Fetch Robotics Features

- 3D Mapping: Enables precise navigation and environment mapping.

- Real-Time Tracking: Provides live updates on robot status and location.

- Virtual Conveyor: Facilitates coordinated item transportation, simulating a conveyor belt system.

Advantages of Implementing Warehouse Robots

- Increased Efficiency: Automating tasks like order picking and inventory management accelerates processes.

- Enhanced Accuracy: Reduces human error, ensuring higher accuracy in order fulfillment.

- Cost Savings: Decreases labor costs by minimizing the need for manual intervention.

- Improved Safety: Robots handle repetitive and hazardous tasks, lowering the risk of workplace injuries.

- 24/7 Operations: Robots can operate continuously without the need for breaks, increasing overall output.

Industry Use Cases

E-commerce

Both Locus Robotics and Fetch Robotics enhance order fulfillment processes, enabling faster and more accurate deliveries to customers.

Manufacturing

In manufacturing settings, robots automate material handling, streamline supply chain operations, and facilitate efficient inventory management.

Healthcare

Within healthcare facilities, these robots transport medical supplies, equipment, and pharmaceuticals, ensuring timely availability and reducing manual labor.

Hospitality

Robots assist in delivering items such as food and amenities to guests in hotels, enhancing service efficiency and guest satisfaction.

Integration with Existing Systems and Cost Analysis

System Integration

Locus Robotics seamlessly integrates with existing Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) solutions through their LRAN platform, ensuring smooth communication between robots and other operational systems.

Fetch Robotics’ use of ROS allows for extensive customization and compatibility with a wider range of hardware and software, providing businesses with the flexibility to tailor solutions to their specific needs.

Cost Considerations

- Initial Investment: The upfront cost of acquiring robotic systems can be significant, but it is often offset by long-term savings and increased productivity.

- Maintenance and Support: Ongoing maintenance costs should be considered as part of the total cost of ownership.

- Customization: Fetch Robotics’ customizable solutions may require additional technical expertise, potentially influencing overall costs.

Customer Feedback and Testimonials

Customers of both Locus Robotics and Fetch Robotics have reported substantial improvements in warehouse operations. For instance, a Locus Robotics client observed a 200-300% increase in picking rates, significantly accelerating order fulfillment times. Similarly, a Fetch Robotics user praised the freight robots' adaptability, highlighting their seamless integration into existing workflows.

However, some clients have noted the high initial costs and reported occasional technical issues that necessitated additional support and maintenance. Despite these challenges, the overall feedback remains positive, emphasizing the long-term benefits of robotic automation.

Future Prospects in Warehouse Robotics

The future of warehouse robotics looks promising, with advancements in artificial intelligence and machine learning poised to further enhance robot capabilities. Predictive maintenance, improved autonomous navigation, and greater interoperability with other smart systems are on the horizon. Both Locus Robotics and Fetch Robotics are expected to continue innovating, driving the adoption of robotics across diverse industries and expanding the potential applications of their technologies.

Conclusion: Selecting the Right Robot for Your Warehouse

Choosing between Locus Robotics and Fetch Robotics depends on your warehouse's specific needs, operational scale, and budget. Locus Robotics excels in collaborative environments with a focus on scalability and worker engagement, while Fetch Robotics offers greater flexibility and customization through its open-source platform. Carefully assess your requirements and consider factors such as integration capabilities, cost implications, and desired functionalities to select the robot that best aligns with your business objectives.